What's the service life of a drive axle? Shandong Lutong provides the answer.

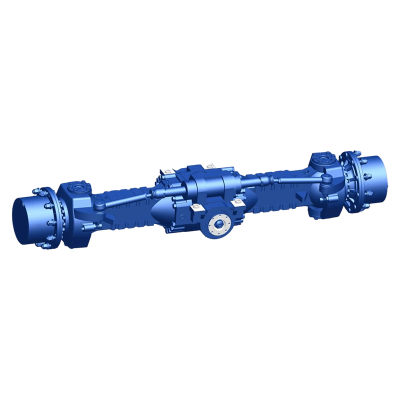

In the operation of construction machinery, agricultural machinery and mining machinery, the drive axle, as a key force transmission unit, its service life directly affects the operating efficiency of the equipment and the operating and maintenance costs. Many users are interested in: what is the service life of the drive axle? Shandong Lutong, as a high-tech enterprise specializing in the field of drive axles, based on many years of industry experience and product development practice, explains in detail the key influencing factors and reveals the secret of longevity of quality drive axles for construction machinery.

I. Key factors affecting the service life of the drive axle

The service life of a drive axle does not have a fixed standard, it is generally limited by three factors: product quality, operating conditions and maintenance method, and there are significant differences in different scenarios

Product quality is the basis:

low-quality drive axles due to insufficient strength of materials and low precision of gear engagement may have a service life of less than 5,000 hours; while high-quality drive axles for construction equipment, thanks to strict process control, can extend their service life to 15,000 - 20,000 hours. For example, for Shandong Lutong loader axles, it uses high-strength alloy materials and robotic welding process, ensuring the products maintain stable performance even under heavy load conditions.

Operating conditions are a key factor:

When operating a wheeled bridge excavator on dirty and wet construction sites, foreign objects can easily enter without adequate protection, causing gear wear and potentially reducing service life by 30%. However, under normal operating conditions and with regular maintenance, the durability benefits can be fully realized.

The method of service determines the duration:

Neglecting gear oil changes, bearing preload adjustments, and other maintenance can lead to drive axle overheating, premature gear wear, and other problems. Statistics show that properly maintained drive axles for construction equipment last over 60% longer than poorly maintained ones.

II. Shandong Lutong: Strong Capability to Ensure the Durability of the Drive Axle

As a key supplier to many famous equipment manufacturers, Shandong Lutong based on technological innovation and strict quality controlProvides reliable support for drive axle life:

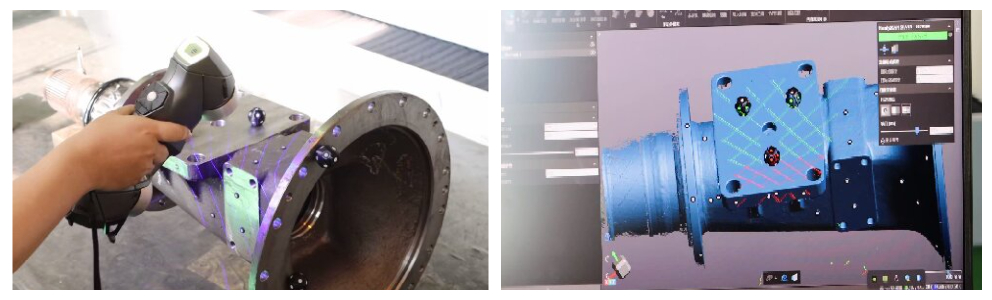

Intelligent manufacturing lays the foundation for quality: the enterprise has built a robotic production line for welding drive axles, an intelligent production line for planetary gearboxes and a specialized testing system, realizing fully automated inspection from parts processing to finished product inspection. The annual output reaches 50,000 drive axles of various types, and the product precision and stability greatly exceed industrial standards.

Customized solutions to meet diverse needs:

In accordance with the operational characteristics of various types of equipment (such as loaders, wheeled excavators, etc.), the parameters of the gear mesh clearance and the pretension of the drive axle bearings are specifically optimized. For example, a specially developed drive axle for mining loaders can adapt to constant heavy load conditions through a reinforced differential structure.

OEM approval confirms the power of:

Thanks to the reliable quality of products, Shandong Lutong has become a long-term partner of leading equipment manufacturers such as SANY, SHANTUI, LOVOL, Leivo, etc. Construction machinery drive axle products are exported abroad and show excellent durability under difficult operating conditions.

III. Practical recommendations for extending the service life of the drive axle

Choosing Shandong Lutong means not only a long service life but also a guarantee of market adaptability. We understand that for our customers, drive axle durability isn't just about the service life figure, but also about local services and adaptability. Our factory currently offers three types of warranties:

Individual guarantee:

According to the load, slope, temperature and other working condition parameters provided by the customer, the drive axle layout design and sample manufacturing can be completed within 30 days;

Guarantee:

The drive axle has a service life of 3,000 hours and a replacement service for defective parts is provided during the warranty period.;

Transaction Guarantee and After-Sales Service:

Support flexible payments and barter transactions, and reserve over 5,000 frequently used accessories to ensure quick response.

Whether you are a mining company, agricultural machinery manufacturer, or construction machinery distributor, Shandong Lutong can provide drive axle solutions tailored to local operating conditions, transforming “long service life” into a digital guarantee of stable operation.

Combined with industry experience, Shandong Lutong reminds users to carry out three-step maintenance: first, fill the specified type of gear oil according to the specification to avoid overheating and wear due to poor lubrication; Second, clean the vent holes regularly to prevent oil seal leakage caused by excess pressure in the axle housing. Third, adjust the gear clearance in a timely manner to prevent tooth breakage caused by impact loads.

Selecting a high-quality drive axle is a prerequisite for extending the service life. Shandong Lutong has always adhered to the principle of “meeting the strict needs of equipment manufacturers” and has continuously improved core manufacturing technologies such as loader drive axles and wheeled excavator drive axles to provide users around the world with reliable and cost-effective construction equipment drive axle solutions.