Shandong Lutong Unites India and Germany in Axle Customer Cooperation, Opening a New Global Chapter

At a time when the global construction machinery industry is accelerating its transformation and international cooperation is becoming ever closer, China Zhizao is opening a new chapter in the global market with its strong technical strength and brand charm.Yesterday, Shandong Lutong Drive axle Manufacturing Co., Ltd.(hereinafter referred to as “Shandong Lutong”) successfully negotiated cross-border cooperation through a high-definition videoconferencing system and from two major potential customers from India and Germany.The three-person team overcame time zone restrictions to provide in-depth consultations on customized axle product requirements, harmonized international technical standards, and innovative collaboration models.This not only enabled Shandong Lutong to seamlessly enter the high-end markets of South Asia and Europe, but also demonstrated through practical actions the core competitiveness and brand appeal of Chinese drive axle manufacturers in the global industrial chain.

These cross-border negotiations are not random, but a deliberate effort by Shandong Lutong based on the global market structure. In recent years, with the booming agricultural machinery and infrastructure construction market, India has become one of the fastest growing regions in the world in terms of construction machinery demand, and the annual growth rate of market demand for high-performance drive axles remains at over 15%; Germany, as the “engine” of the market, is one of the fastest growing regions in the world in terms of demand for construction equipment. In the European industry, construction machinery and equipment are known for their precision and high quality, and strict requirements are placed on the technical standards, reliability and service life of drive axles. After vetting customers, Shandong Lutong's foreign trade team finally selected these two key customers who represented the potential of the South Asian market and the European technological benchmark, laying a solid foundation for such precise alignment.

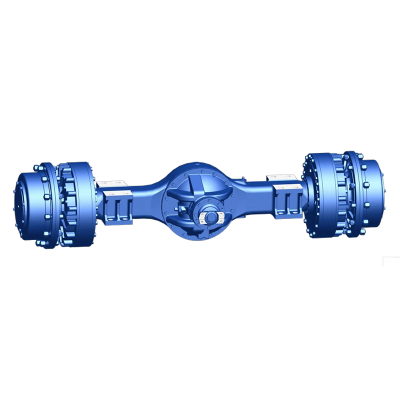

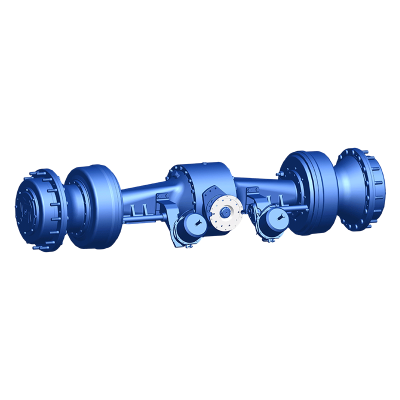

At the meeting, Zhongshan Donglutong conveyed its sincere congratulations to Inde customers through a video. Since the drive axle is the "heart" and "backbone" of construction equipment, its performance directly determines the operating efficiency and service life of the equipment. Shandong Lutong has been active in this field for more than 30 years and has always adhered to the concept of "International Technology Benchmarking, Global Quality Service". This time, the company hopes to use customized solutions to meet the different needs of customers from the two countries and achieve mutually beneficial development between the two countries. three parties. During the subsequent on-demand docking session, the three parties engaged in detailed communication for two hours. The customer representative made high demands on the level of technical standards, and also submitted detailed documents on technical parameters, hoping that Shandong Lutong could provide solutions that meet these requirements. Considering the individual needs of customers from the two countries, the joint team consisting of Shandong Lutong's foreign trade department and technical experts quickly responded and organized targeted questions and answers, and also a software demonstration. The technical director on site explained how the 3D modeling software works, demonstrated the design innovations of the specially designed drive axle through the 3D model, and assured that Shandong Lutong will definitely provide customers with the perfect answer.

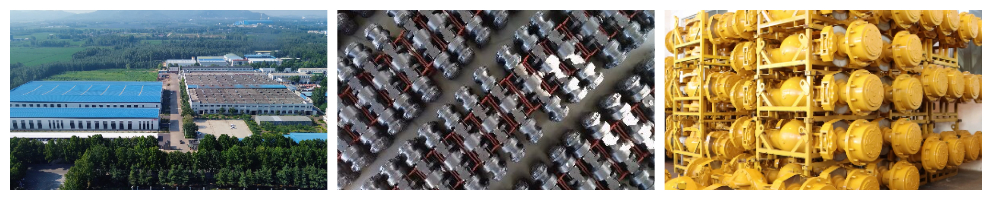

During the production line demonstration, the foreign trade department took customers on a “tour” of Shandong Lutong's intelligent production base via real-time video communication. The visual display of the entire process, from cutting raw materials to assembling finished products, allows customers to intuitively feel the production power of the enterprise: in the workshop, several CNC machining centers perform high-precision operations with high positioning accuracy; Fatigue strength testing system simulates the operating condition of the drive axle under various operating conditions and continuous testing ensures smooth operation; The automated production line automates the process from making parts in real time to releasing the finished product offline, and the production efficiency is 40% higher than traditional production lines.

Efficient and smooth cross-border communication is supported by the highly qualified personnel of Shandong Lutong Foreign Trade Department. To ensure the precise connection of the meeting, the team has carried out preparatory work in advance: according to the customer's preliminary requirements, the joint technical department has carried out special research and generated many alternative solutions; Taking into account technical issues of interest to the customer, a preliminary analysis was carried out. all main technical parameters were agreed upon in advance; Taking into account the difference in time zones between the two countries, the team scheduled the meeting time for 17:00 Beijing time and at the same time provided a professional English translator to ensure there were no barriers to communication. In addition, the team prepared market reports, competitor analysis and product customization examples in the customer's industry in advance, providing clients with a full range of reference databases.

The high recognition of customers is due to Shandong Lutong's solid experience in the field of drive axle manufacturing, accumulated over more than 30 years. As a core enterprise specializing in the research, development and production of drive axles for construction, agricultural and mining machinery in China, the company has taken the leading role in building an integrated R&D-Production-Test-Service production chain in the industry. The company has the intellectual power production base of 150,000 square meters with an annual production capacity of 50,000 sets of various drive axles, and can produce a full range of drive axle products with various load levels from 1 ton to 50 tons, including loaders, excavators, tractors, mining trucks and other equipment. fields.

In terms of quality control, Shandong Lutong has implemented a whole-process quality control system covering the procurement of raw materials and the delivery of finished products, realizing that “every detail can be tracked and every process can be monitored.” Through strict QUALITY CONTROL, the company's products have successfully passed the ISO9001 quality system certification and have become the main supplier to such FAMOUS domestic enterprises as SANY, XCMG, SHANTUI, LINGONG Etc. Despite the fact that the products are supplied in bulk TO THE DOMESTIC MARKET, they are also exported to other countries. IN MORE THAN 20 COUNTRIES AND REGIONS SUCH AS Russia, Belarus and Iran, and have won a GOOD reputation in OVERSEAS markets.

Shandong Lutong said: “Such precise docking with Indian and German customers is the successful practice of the company's online + offline integrated development model. In the future, we will continue to use overseas platforms to deepen the three-dimensional service system of "online precision docking + offline technical support + overseas service centers" and establish localized service teams in key markets such as Southeast Asia and Africa to provide customers around the world with a full range of services from customized product customization, technical training and after-sales service. At the same time, the company will accelerate technical cooperation with research institutes, jointly build a drive axle production R&D center, and promote the upgrading of products to high-quality and intelligent levels, so that more customers around the world can experience the power and charm of China's intelligent manufacturing.”

Shandong Lutong's development trajectory from domestic core enterprises to global market players is a shining example of the transformation and upgrading of China's equipment manufacturing industry. These cooperation negotiations with Indian and German customers not only opened up a new path for the company's global development, but also gained valuable experience in China's drive axle manufacturing to enter the high-end international market. I believe that in the wake of global economic integration, Chinese enterprises represented by Shandong Lutong will rely on its superior technical strength, high product quality and perfect service system, so as to occupy a more central position in the global industrial chain and write more mutually beneficial chapters in China-overseas cooperation.