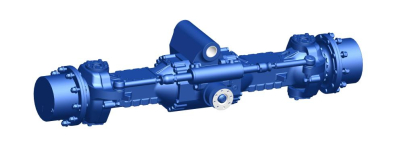

Shandong Lutong's 400hp wet brake drive axle sets new standard

With the global trend of agricultural intensification and large-scale development, high-power tractors have become the main source of power in modern agriculture, and their productivity continues to expand.In harsh operating conditions such as heavy-duty field hauling and challenging ramp work, the reliability, durability, and high cost of traditional braking and transmission systems have become key barriers to improving the efficiency of high-end agricultural machinery.Recently, Shandong Lutong Heavy Industry Machinery Co., Ltd., which has been engaged in the production of drive axles for more than 30 years, officially released a wet brake drive axle specially designed for 400 horsepower tractors.This step is not a simple upgrade, but a major advancement in braking and differential lock technology based on an understanding of scenario requirements and a modular platform.It marks a significant step for Shandong Lutong in customized high-end agricultural drive axle solutions, providing users with smoother, more reliable and enhanced lifetime drivetrain options that redefine tractor chassis performance in this horsepower segment.

1. Market demands and an individual approach to each client: the core value of an exclusive drive axle

With the increasing use of farmland and the popularization of sophisticated farm implements, tractors rated at 400 horsepower and above are performing increasingly complex tasks, from towing large subsoilers to hauling grain bins weighing tens of tons for reloading. The chassis transmission system, especially the drive axle, provides extremely high performance. requirements. Although the cost of the traditional drum brake drive axle is reasonable, when working with high intensity and high load, there are disadvantages: the reduction of brake temperature can easily lead to unstable braking force, and there are safety risks when working on a ramp; Brake pads wear out quickly, increasing maintenance frequency, user operating costs and downtime.

Through top-notch research, Shandong Lutong's technology and marketing team has pinpointed the core needs of high-end users and equipment manufacturers - not only a stronger drive axle, but also a system solution that can provide continuous braking under severe conditions, high reliability and low maintenance costs. Based on this, the company has embarked on special research and development to overcome the dependence on drum brake circuit and develop a new wet braking product as the basis for the segment 400 horsepower, demonstrating its strategic transformation from “making products” to “providing scenario-based solutions.”

2. Evolution of Fundamentals: Wet Braking Revolutionizes Reliability and Cost

The main improvement of the new product is the elimination of traditional drum brakes, and all series are equipped as standard with a multi-disc wet braking system, which provides a revolutionary increase in the performance of 400 horsepower tractors. The system immerses the brake friction linings in a special cooling oil, and the heat generated during braking can be quickly absorbed and dissipated by the oil, which greatly improves the efficiency of heat dissipation. For large tractors that brake frequently and operate on inclines for long periods of time, the effect of temperature reduction can be ignored, and the braking torque always remains stable and linear, which greatly improves operating safety under harsh operating conditions.

From an economic point of view, the oil bath significantly reduces the wear of friction pairs, and the service life of brake pads is exponentially longer than the service life of drum brakes. At the same time, it isolates contaminants such as dust, soil and moisture in the field, thereby avoiding excessive wear and corrosion. This directly translates into longer maintenance intervals, fewer parts to replace and lower long-term costs. Although the initial investment increases slightly, the total cost of ownership (TCO) throughout the life cycle is more competitive, demonstrating the core value of Shandong Lutong's technological innovation to create the best end-to-end operating system. benefits for users.

3. Smart Advantage: Electronic differential lock optimizes traction control.

As part of the brake system upgrade, the new product integrates sensors to intelligently control the Electronic Differential Lock (EDL) to optimize power distribution and traction. Considering slippery conditions such as single-sided wheels gripping mud and soil, the system provides fully automated, intelligent control compared to a traditional manual differential lock.

A high-precision wheel speed sensor monitors the difference in speed between the left and right wheels in real time. When it detects that a wheel is slipping and idling (the speed difference exceeds a threshold value), the Electronic Control Unit (ECU) immediately commands the solenoid valve to operate, quickly locking the differential, and transmits torque to the attached wheels, helping the vehicle quickly recover from the fault and ensuring continuity of operation. This feature not only reduces the driver's workload, allowing him to concentrate on operating the farm tool, but also reduces tire wear, soil damage and power loss, while reducing stress on the drivetrain, extending component life and realizing the “high power + high intelligence” principle.”

4. Modular design: customization and future upgrades possible.

The modular design provides extremely high product flexibility. Equipment manufacturers can combine modules on demand, quickly create custom models and shorten the development cycle of all equipment; end users can carry out maintenance and upgrades at the module level, simplifying the process and reducing reuse costs. More importantly, the platform demonstrates Shandong Lutong's deep management of various subsystems and leaves room for future integration of advanced sensors, wire-controlled chassis functions and adaptation to new energy systems.

5. Proven durability: 30 years of experience has created reliable quality

The stable introduction of advanced technology is inseparable from the support of a strong R&D and production system. Shandong Lutong has been actively engaged in the production of drive axles for 30 years, and has accumulated extensive experience in materials, technology, precise control, etc. In order to withstand the torque of 400 horsepower, the drive axle gears are made of high quality alloy steel, which undergoes case hardening, hardening and precision grinding to ensure strength and smooth operation. engagement; The bridge body is made of high-strength steel and has an optimized design with excellent resistance to bending and torsion; All key components undergo stringent cleaning, testing and bench fatigue testing to ensure factory quality.

This wet brake drive axle is the practical result of Shandong Lutong's commitment to “listening to customers, focusing on technology and demanding high quality”, as well as the company's declaration of comprehensive development in the field of high-quality agricultural machinery and expanding the capabilities of modern agriculture around the world. Through the supply and introduction of its products, Shandong Lutong is expected to set a new standard in the field of high-end agricultural machinery drive axles and cooperate with partners to elevate the production technology of high-power tractors to a new level.