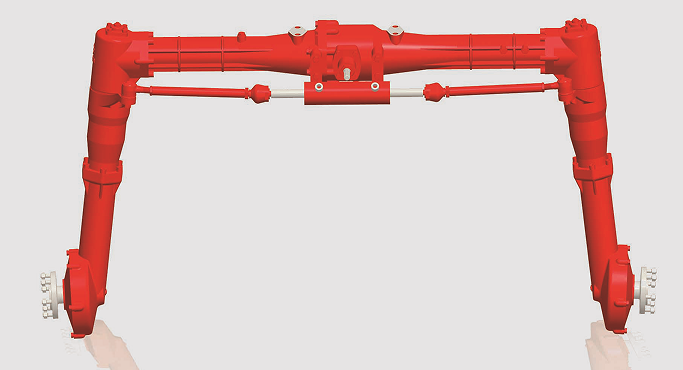

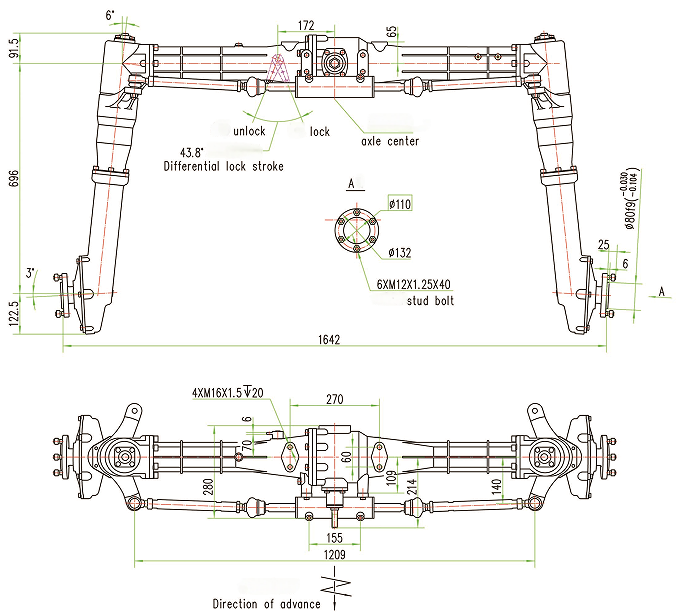

Sprayer rear axle 25 hp

1.Low consumption and reduced costs

2. Super durable

3. Full technical support for the process

4. No hidden defects

5. Short delivery cycle

Main characteristics:

A wet spraying machine in the mining industry is the key equipment for “formwork under the pressure of concrete” in mine tunnels, passages for wells, underground chambers and other projects. It is mainly used to reinforce surrounding rocks and molding supports. The shaft of a wet spraying machine is the main component of energy transmission, which directly connects the hydraulic electric motor for wet spraying is connected to a concrete pump and a rotary platform for injection, which is responsible for the accurate transformation of the power into a coordinated action “Mixing the concrete-shield under high pressure”.

Unlike conventional engineering drive shafts, shafts of machines for wet spraying for mining should be adapted to special working conditions in mines: high underground humidity, high dustiness, strong shocks and aggressive media. Their main value lies in solving the three main problems associated with the mounting of mining, - “lack of catho at high loads.”, Lack of damage in severe operating conditions and high stability during prolonged operation ”, as well as ensuring the effective operation of the machine for wet spraying with the volume of concrete pouring from 3 to 8 m3 per hour and observing critical time to ensure safety in mines.

Impact resistance and wear resistance:The shaft body, made of high-strength alloys, can withstand the instantaneous impact load during concrete transportation, and the wear rate is 70% lower than that of ordinary transportation, and is suitable for high-intensity mining work on average 8-10 hours a day.

Dustproof and anti-corrosion:It adopts double protection design, which can prevent more than 99% of stone and cement dust from entering into the shaft body and solve the problem of corrosion from underground moisture.;

High load stability:By optimizing the gear design and shaft diameter, the transmission efficiency will reach over 97%. Even if concrete slump fluctuates, the feed pump speed can still be maintained at a stable level, eliminating concrete delivery defects and voids caused by uneven power, and preventing infection transmission.

Main technical parameters:

Overall Gear Ratio |

21.43 |

Angle of rotation |

25° |

Steering cylinder stroke |

67.5mm |

Max. working pressure |

16Mpa |

Request for drive axle oil (API standard) |

GL-5; 85W/90 Transmission oil (for use at temperatures above -12°C) |

Input shaft spline parameter |

EXT 127x1.27Mx20P |

The company's core capabilities and mine-specific services

1. Individual solutions for working conditions in mines

Given the differences in the conditions of work on various mines and tunnels, the company conducts in -depth studies of the characteristics of the working environment, the requirements for the operation of equipment and safety specifies, and also offers exclusive solutions for the shaft body for the entire process - from the choice of material, design design to optimization of the performance. Money mines, or the requirements for portable and efficiency in the design of tunnels, individual design can significantly increase the performance of the mine and the efficiency of equipment, as well as create long -term value for customers.

2. Security and quality control in mines

Strictly observe the "Safety Rules for Mining Equipment" and create an exclusive quality control system :

Material Quality: All steels have passed certification, and each batch of raw materials must be tested for impact toughness to ensure that the shaft shell will not be brittle in the low temperature environment underground.

Completion of Testing: The finished product must pass a simulated working environment test - it can operate continuously in a simulated environment for 100 hours without failure before leaving the factory; Safety certification: The shaft body and auxiliary components are certified and can be directly used in underground mining in coal mines and non-coal deposits. mines.

3. “Underground direct” service for mining clients

Considering the complex underground work and slow maintenance response in mines, we offer customers effective solutions by optimizing maintenance processes and technical support.

Fast response mechanism: after receiving a message about a malfunction requiring repair, activate the emergency dispatching system and send a professional maintenance team to provide quick access to the mouth of the mine and timely maintenance work.

Guarantee of the supply of spare parts: Create a platform for supplying spare parts, update the reserves of frequently used spare parts in real time and help customers place orders online. We work as professional logistics companies and use special transport equipment to ensure safe and quick delivery of spare parts to the mine. At the same time, we provide services of the “priority distribution of spare parts” for customers who have long been cooperating to reduce transportation time.

The general idea of the wet spray and the shaft of the wet sprayer for mining

1. Why do wet sprayers use wet sprayers instead of dry mines?

Many people are wondering why wet sprayers are preferable for fastening in mines. The main reasons are directly related to safety in mines and operating conditions.

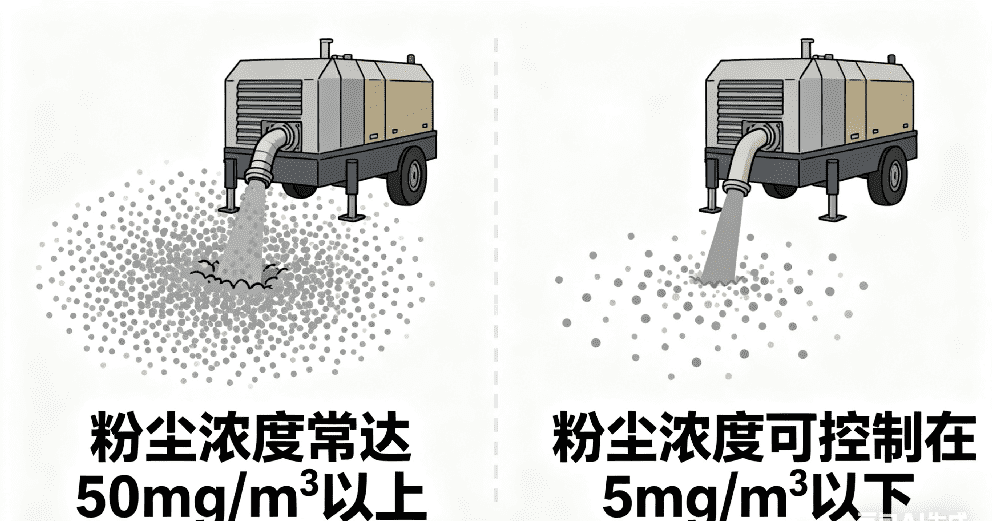

The fight against dust: a dry spraying machine is a “dry cement-sand and gravel mixture + water injection in place”, while the concentration of dust often reaches more than 50 mg/m3, which can easily cause pneumoconiosis in miners; While the car for wet spraying is a “direct injection of pre -mixed wet concrete”, dust concentration can be adjusted at the level below 5 mg/m3, which meets the requirements of labor hygiene in mines .;

The quality of the base: Concrete, applied by dry spraying, has insufficient strength due to the “uneven addition of water in place”, and its density leaves much to be desired and is easily cracking; Concrete, applied by wet spraying, is sprayed under high pressure, concrete has high density, strong adhesion to the surrounding breed, and the service life of the fasteners increases by more than 3 times, which reduces the costs of alterations at the later stages of development of the mine. ;

The efficiency of work: the volume of the car injection for dry spraying is only 1-3 m3 per hour, and 2-3 people are required to add water and mixing; The volume of the car's injection for wet spraying is 3-8 m3/h, and one person can control it, which is especially suitable for the needs of “quick support” in the mines and the stable transfer of the shaft of the machine for wet spraying are the main guarantee of effective work.

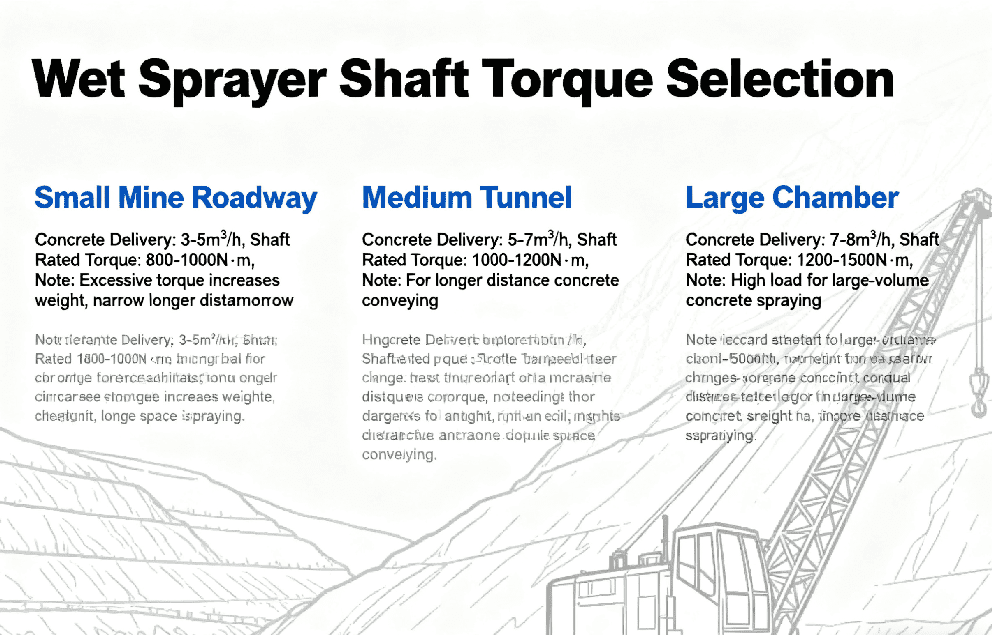

2. How to choose the right load for a wet spraying machine shaft in mining? No, the bigger, the better!

When selecting a shaft for installing a wet spraying machine in the shaft, the main focus is on the “concrete transportation performance of the wet spraying machine” and the “size of the underground working surface”, rather than just the heavy load.:

Small bore hole: suitable for wet spraying machine with a capacity of 3-5m3/h, which corresponds to the rated torque of the shaft body of 800-1000Nm, excessive torque will cause the equipment weight to increase, which is not conducive to movement in narrow underground spaces.

Medium-sized tunnel: The wet spraying machine with the output of 5-7m3/h and the rated shaft torque should be 1000-1200N.m to cope with long-distance concrete transportation.

Large Chamber: For a wet spraying unit with a capacity of 7-8 m3/h, a shaft housing with a rated torque of 1200-1500 Nm is required to meet the high load requirements of large-scale concrete spraying.

Simply put, the load on the shaft housing can be matched to the performance of a wet sprayer. Overloading will lead to premature wear of the shaft housing, while underloading will result in power loss and increased energy consumption.

3. 3 rescue methods for servicing the shaft of an underground wet spray machine

The underground mine environment is complex, and improper mine shell maintenance not only impacts operations but can also lead to safety accidents. Mastering these three skills is essential.

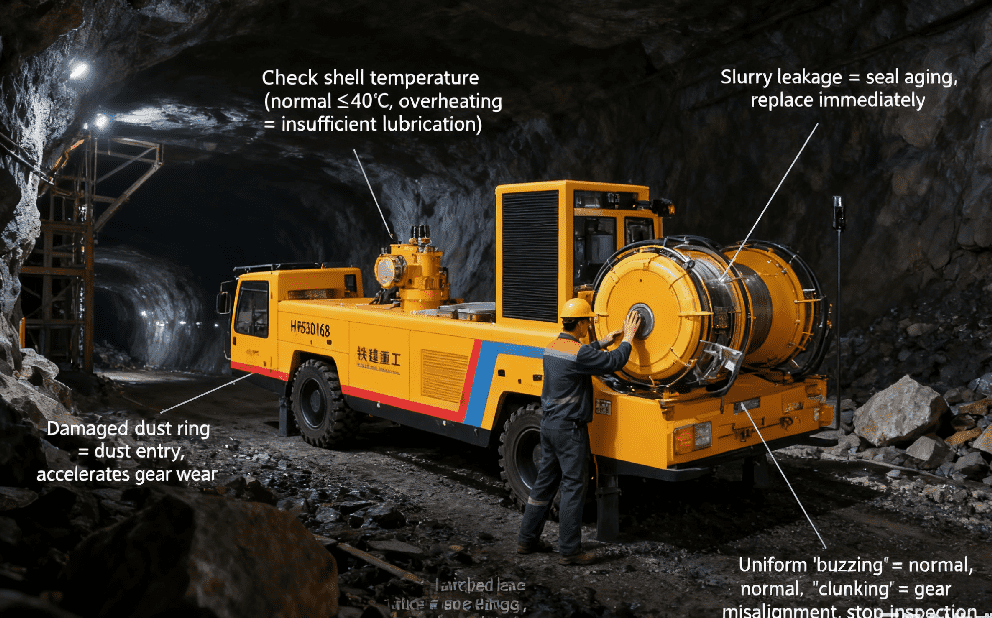

"One touch, two views and three listening" before switching: measure the temperature of the shaft housing, usually it should be ≤40 ℃, and if it exceeds, possibly, lubrication is not enough; Check if the sludge proceeds from the seal, which indicates the aging of the seal and the need to replace it. It is subject to immediate replacement to avoid the grout entering the shaft case and its stuck inside. Regardless of whether the dustproof ring is damaged or not, the dust will fall into it and accelerate the wear of the gear; Listen to the sound of work, this is a normal phenomenon - a uniform "buzz", and there may be a "sound of a blow." The gear is installed incorrectly, and it must be stopped to check to prevent the shaft case breakdown and a sharp stop of the machine for wet spraying. ;

Regular lubrication "choose the right oil and do not mix": it is necessary to use lithium-based grease designed for mines, which is resistant to high pressure and dust contamination, and ordinary mechanical oil cannot be used. It is refilled once every 20 hours of operation, and dust is removed during refilling. The port must be cleaned before filling to avoid "dust intrusion."

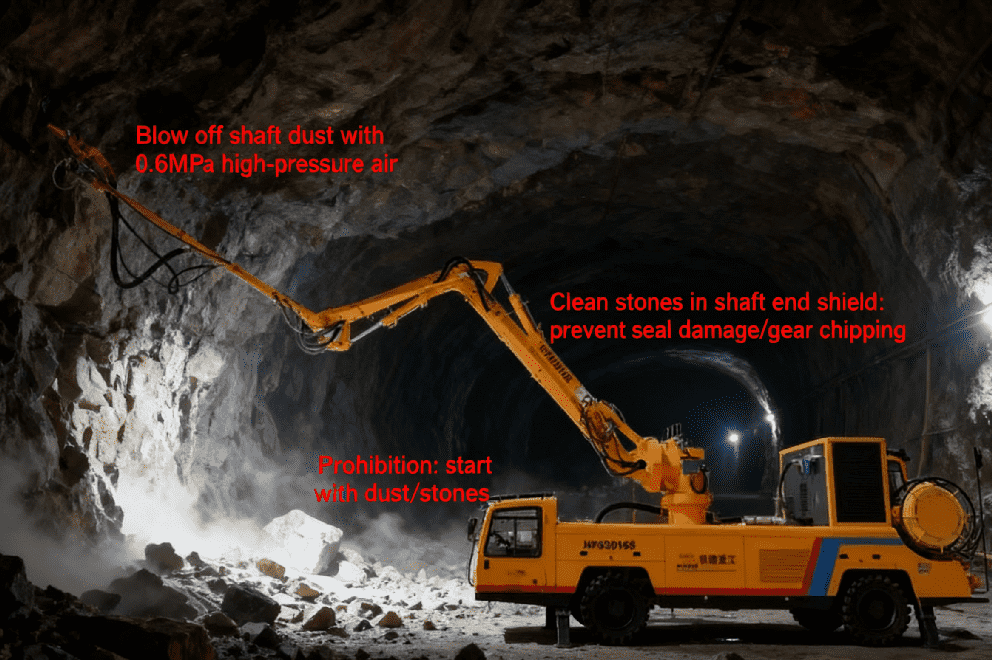

“Cleaning before starting” after explosive work: after explosive work in the mine, the surface of the machine for wet spraying and the shaft body will be covered with a large amount of stone dust and gravel. Before starting, it is necessary to use high -pressure wind to clean the surface of the shaft housing from stone dust, gravel should especially carefully clean in the protective shell of the end of the shaft in order to avoid gravel entering the shaft case, which can lead to damage to the seal or failure of the gearbox. It is strictly forbidden to start working with dust and gravel.