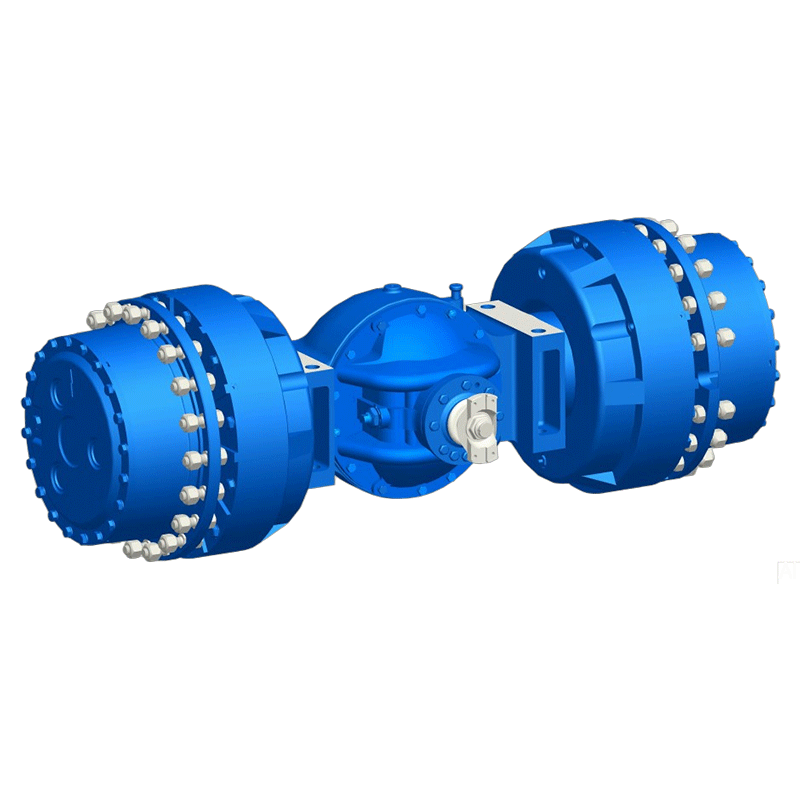

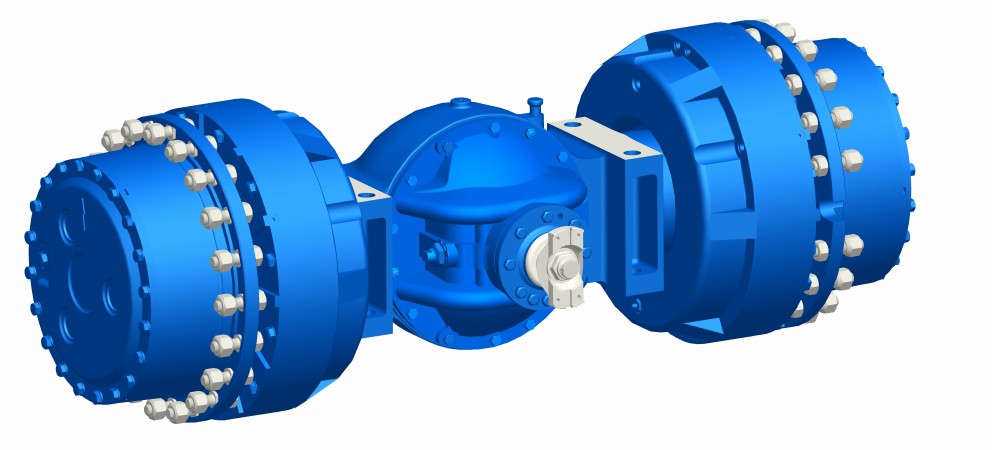

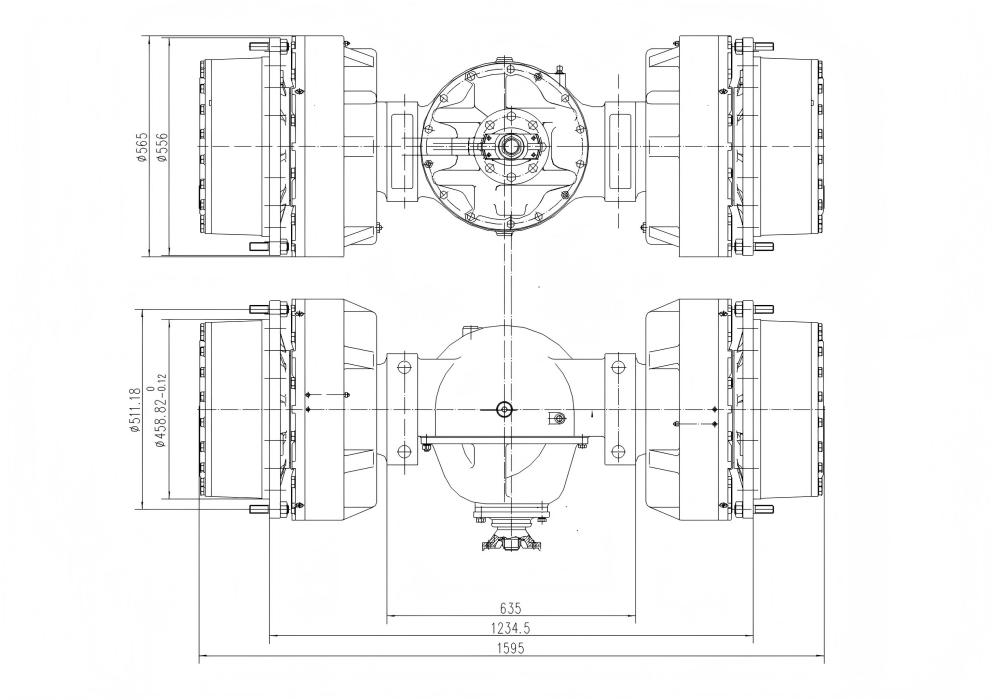

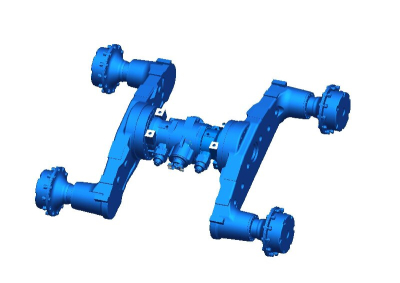

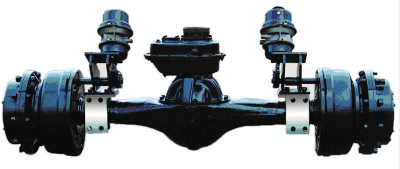

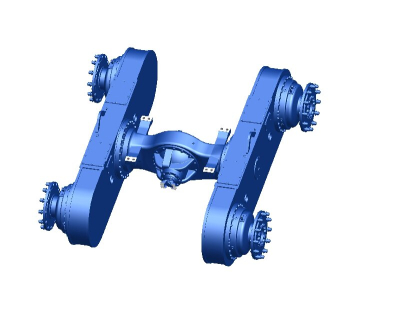

Drive axle of an underground loading and unloading machine 2 m³

1. The front axle is equipped with a No-spin differential, providing 100% anti-slip protection on muddy surfaces.

2. Posi-stop wheel brakes with spring engagement and hydraulic release integrate the service and parking brake, ensuring safety and reliability.

3. Wheel hub oil seal design provides better adaptation to wet and muddy conditions.

4. The key components are imported from internationally famous brands, have a long service life.

5. The one-piece cast steel axle has high rigidity, and the two-stage reducer design is rational.

6. Suitable for completing 2 cubic meter underground loaders.

MAIN CHARACTERISTICS:

Underground Loading and Unloading Machine 2 m³ Drive Bridge designed for underground scrapers with a volume of 2 m³.The monolithic steel cast bridge housing is equipped with a self-locking No-Spin differential (LSD) on the front axle.The wheel assemblies are equipped with a combined braking system featuring a spring brake and hydraulic release (POSI-STOP), as well as floating oil seals.This technical solution demonstrates optimized adaptability and increased operational reliability, specifically created for extreme conditions in underground mining.

MAIN TECHNICAL PARAMETERS:

Overall overall gear ratio |

26.118 |

Maximum input torque |

2668N.m |

Maximum load on the bridge |

18160Kg |

Braking Systems |

POSI-STOP Hydraulic Brake / Multi-disc Wet Brake with Forced Cooling |

Oil pressure with the parking brake on |

10.4MPa |

Working volume of the single-sided brake |

163.9ml |

Braking moment of one side |

20000N.m |

Oil for cooling brakes and reducing braking force |

Hydraulic Oil L-HL46 |

Requirements for oil for the drive axle (API classification) |

GL-5: 85W/90 gear oil (use above -12°C) GL-5: 80W/90 gear oil (use above -26°C) |