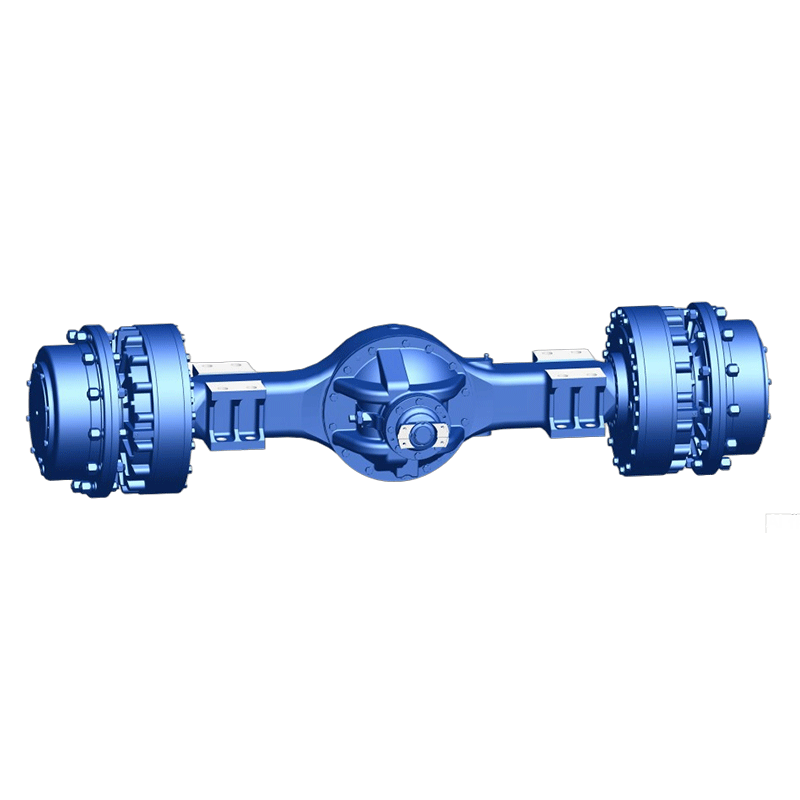

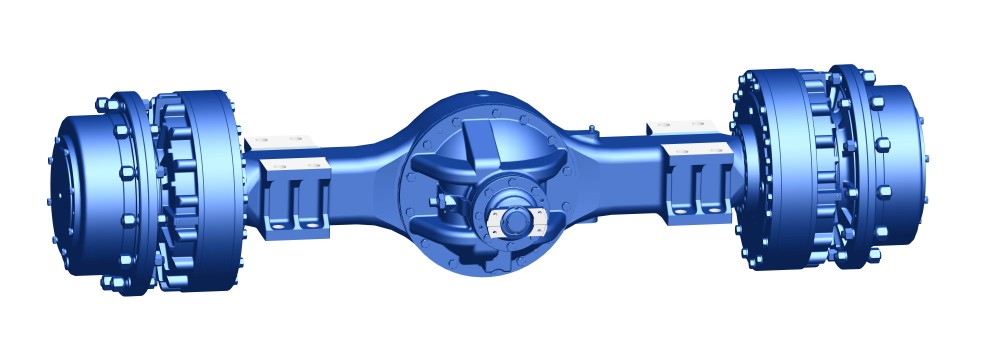

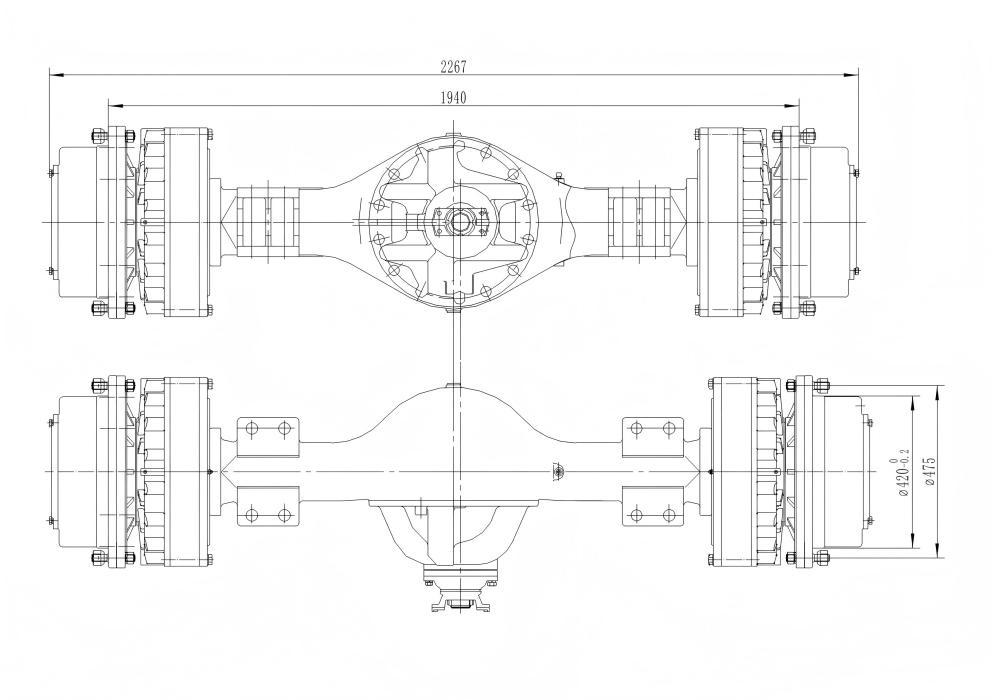

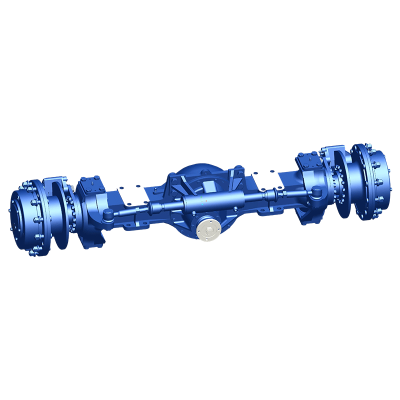

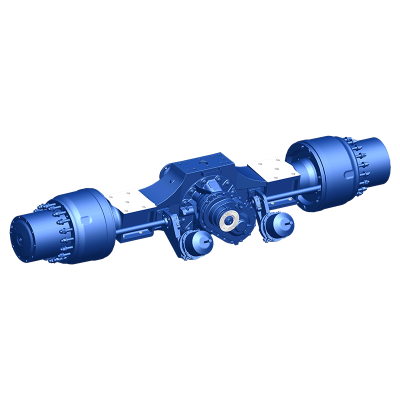

Drive axle of an underground loading and unloading machine

1. The final drive adopts hypoid Gleason bevel gears, ensuring high efficiency and low noise.

2.The wheel reducer is designed according to the NGW planetary scheme, compact and rational.

3. One-piece steel bridge case with high rigidity and large load capacity, the two-stage reducer design is rationally designed.

4. The floating seal design on the wheel is well adapted to wet and dirty conditions.

5. Braking is carried out using combined wet brakes (working and parking), which provide high braking torque, smoothness and reliability.

6. A no-spin differential can be installed to improve cross-country ability.

7. Suitable for 2.5-3m³ underground loaders.

MAIN CHARACTERISTICS:

The drive bridge of the underground loading and unloading machine is made of a monolithic steel bridge body.The main gearbox is equipped with Gleason's conical spiral gear transmission, while the wheel part uses an NGW-type planetary gearbox.The differential is equipped with the option to install an anti-slip device No-Spin.The braking system integrates working and parking wet brakes, featuring rational design, smooth operation, and reliable performance characteristics.

MAIN TECHNICAL PARAMETERS:

Overall overall gear ratio |

22.853 |

Maximum input torque |

5000N.m |

Load on one bridge |

25000Kg |

Parking brake engagement moment (single-sided) |

16000N.m |

Braking torque during movement (one-sided) |

20000N.m |

Pressure Relief During Parking |

7.5Mpa |

Brake fluid pressure of the working brake. |

8Mpa |

Removing the parking brake (one-sided) |

112ml |

Working volume of brakes (single-sided) |

104ml |

Requirements for oil for the drive axle (API classification) |

GL-5: transmission oil 85W/90 (use at temperatures above -12°C) |

Brake fluid and cooling fluid for brakes |

Hydraulic Oil L-HL46 |