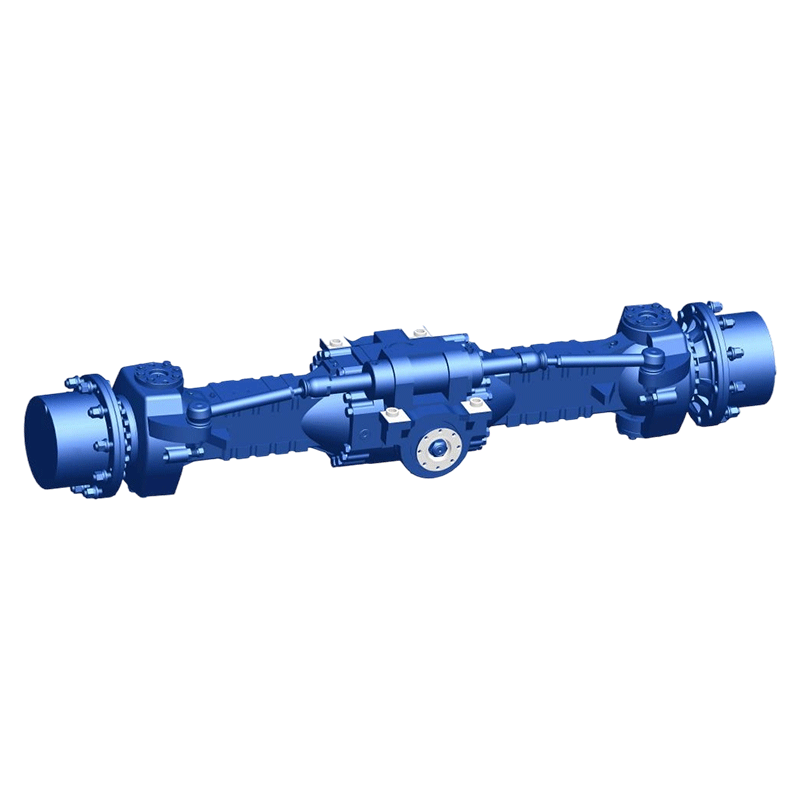

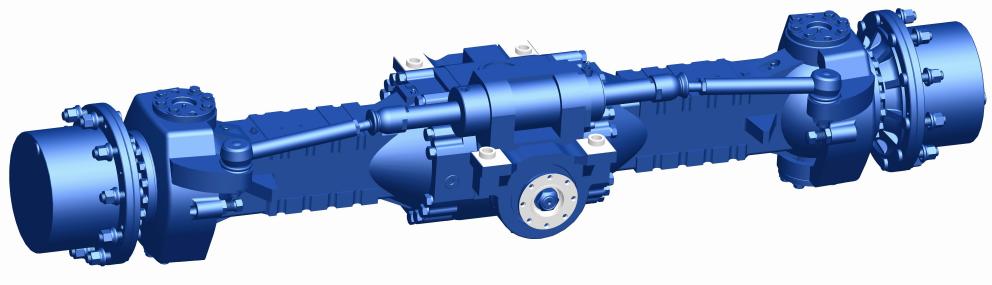

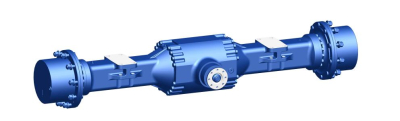

Drive axle for a 15-ton wheeled excavator

1.Outstanding data transmission performance

2. Significantly reduced noise level

3.The bridge body is made of malleable cast iron.

4. Stable and long-lasting braking

5. Several gear ratio options

MAIN FEATURES:

In the industry of wheeled excavators, a joint increase in power and reliability has always been a key area of technological breakthroughs. The company Shandong Lutong Heavy Industry Machinery Co., Ltd., which has more than 30 years of experience in researching and developing leading bridges of construction equipment, developed the original leading bridge of the steering, suitable for 15-toned wheels Excavators. Conditioning technical advantages and innovative design, this product has established a new performance standard in difficult operating conditions. The main gearbox has a leading international technology of conical wheel wheels, the transmission efficiency has been increased to more than 95%, the noise level is significantly lower than in traditional direct hooded wheels, and it can still ensure uninterrupted work in heavy work operating conditions. Dynamic carrying capacity is up to 13,000 kg, and a multi-disc wet brake provides more reliable emergency braking. The leading bridge of the 15-ton wheel excavator developed by Shandong Lutong was delivered by a number of domestic and foreign manufacturers and provided long-term cooperation with Sany, Shantui, Lovol, Lovol, Lovol, Lovol, Lovol, Lovol Liugong, UMG, PTZ and many other manufacturers of equipment in the country and abroad. The Aquarius of the Aquarius on the leading bridges of Shandong Lutong is less than two percent, and the quality of its products is located on the front edge of the industry. There is an intensive excavation of soil when mining, logging on crossed areas or flexible transformations in Communal farm, the 15-ton leading bridge Shandong Lutong can stand out against the general background.

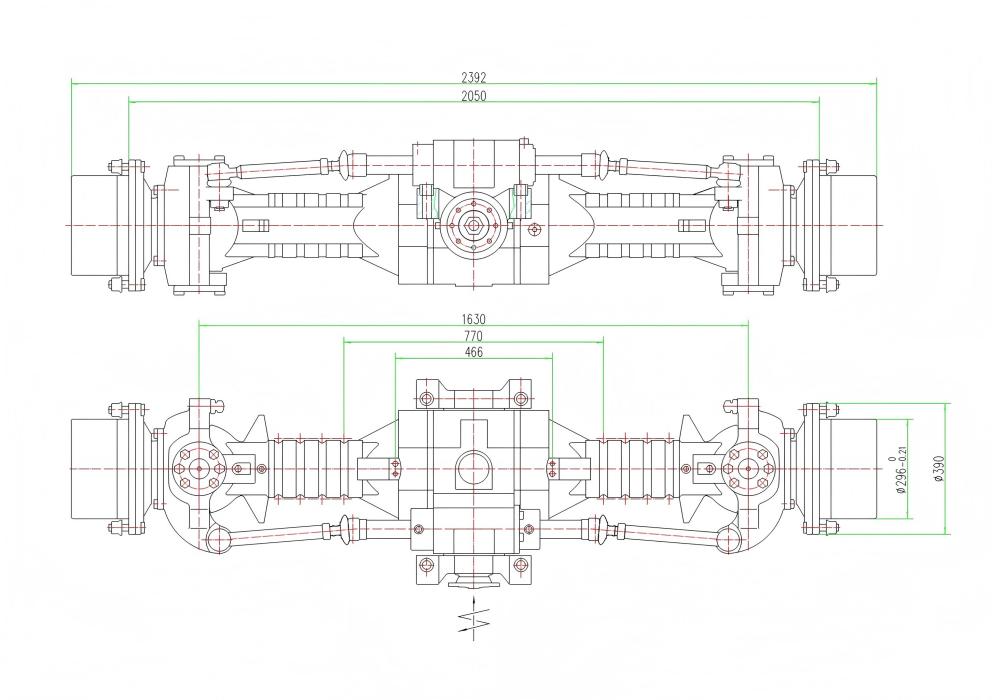

MAIN TECHNICAL PARAMETERS:

Overall overall gear ratio |

14.77/16.91/22 |

Maximum output torque |

50000N.m |

Dynamic load on the bridge |

13000Kg |

Braking torque (one-way) |

21000N.m |

Brake system oil pressure |

4Mpa |

Brake displacement |

45-128ml |

Steering angle (inner/outer wheel) |

37°/30° |

Steering cylinder pressure |

14Mpa |

Drive axle oil requirements (API classification) |

GL-5: transmission oil 85W/90 (use at temperatures above -12°C) |

Oil for brakes and hydraulic cylinders |

Hydraulic oil L-HL46 |

So, what is the difference between a wheeled excavator and a regular crawler excavator?

Wheel excavators use pneumatic or solid tires as walking devices similar to the wheel of the car, and move along the tires, in contact with the ground. Supervisory excavators use metal rails of the caterpillar chain (consisting of caterpillar shoes, links, drive wheels, etc.), which are in contact with the ground through the ground through the ground through the ground through the ground through the ground The caterpillar is based on a rail chain for rolling and moving.

Wheel excavators are more suitable for “strengthened road surface + flexible work at short distances.” With the same carrying capacity, the cost of wheeled excavators is usually 5-15% lower than that of caterpillar excavators (since the tire design is easier than a caterpillar chain). Gusenic excavators are more suitable for “work on difficult relief + in difficult conditions”.

Wheel excavators develop high speed (usually 20-40 km/h), can move directly along the road (for some models you can get a license) and do not need trailers to move at short distances. They are suitable for operations of “multi -point dispersal and at close range”. (for example, interregional maintenance in the city). Senary excavators move extremely slowly (usually 3-5 km/h), and direct contact of a caterpillar mover with a solid road surface can lead to serious damage to the road surface (extrusion from the groove), therefore, when moving over long distances, it is necessary to use on-board trailers that are suitable for “concentration at one point, scripts. long -term operation ”(for example, at large construction sites). If the wheel excavator complies with the standards for vehicles (such as speed restriction, lighting and braking), it can be issued by a license and use the rules of the road). distances. Otherwise, they can be punished by the road administration (due to damage to the road surface). They should receive a “permit for transportation in excess of the established limits” and transported by trailer. The benefits of the advantages of fast transportation without a trailer and slight damage to the hard road surface Wheel excavators have become widely used equipment in areas of such areas and rural infrastructure, allowing them to be flexible between streets and construction sites. And behind all this efficient work, it is worthwhile to the fact that it The main data transmission system is inseparable from the stable operation of the main system. The Bridge of our wheeled excavator is one of the key components. He accurately transfers the engine power as a “power center” and stably controls the direction of movement and stability in difficult road conditions. It is not necessary to talk about a smooth increase in speed during the transition or response to the potholes on the road during operation, this leading bridge can be reliably adapted, effectively reducing the efficient operation of the wheel excavator with frequent Starts and turning, as well as creating a strong transmission basis for each operation. Engineering operation allows you to fully use flexible characteristics.