Precise control, quality, ingenuity, build a good bridge-Shandong-Lutong Leading Bridge -Precise control, quality, ingenuity, build a good bridge

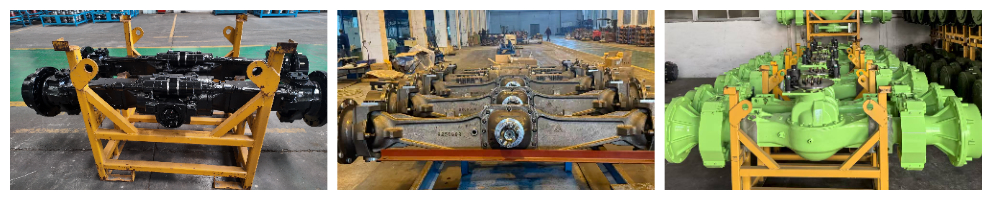

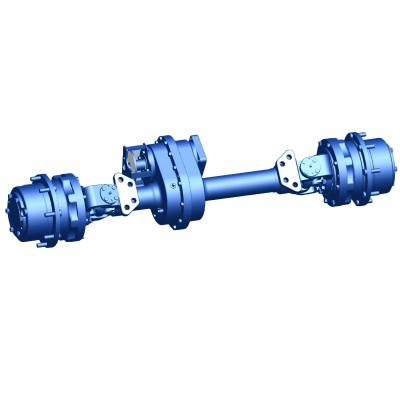

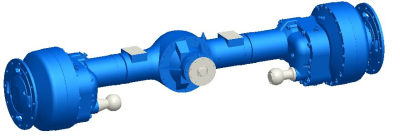

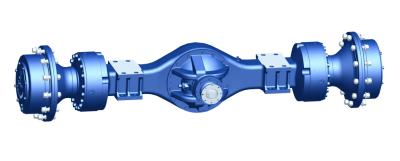

On noisy mine work sites, the drive axles of mining equipment can withstand long-term operation under heavy loads; in busy agricultural fields, drive axles of agricultural machinery power implements for deep plowing and tillage; In logistics warehouse parks, the drive axles of telehandlers precisely drive equipment for flexible transportation - the drive axle, as the “power heart” of construction, agricultural and mining equipment, directly determines the operating efficiency, operating safety and service life of the entire machine.Shandong Lutong Heavy Industry Machinery Co., Ltd., which has been specializing in the production of drive axles for many years, has always taken “quality as the top priority” as its development genetics, establishing a detailed quality control system covering the entire production process.From the receipt of raw materials to the release of finished products, every stage is strictly controlled to high standards.Through professional testing and a commitment to craftsmanship, the company ensures reliable protection of superior quality across its entire product line, including forklift drive axles, telehandler axles, backhoe loader axles, and more.

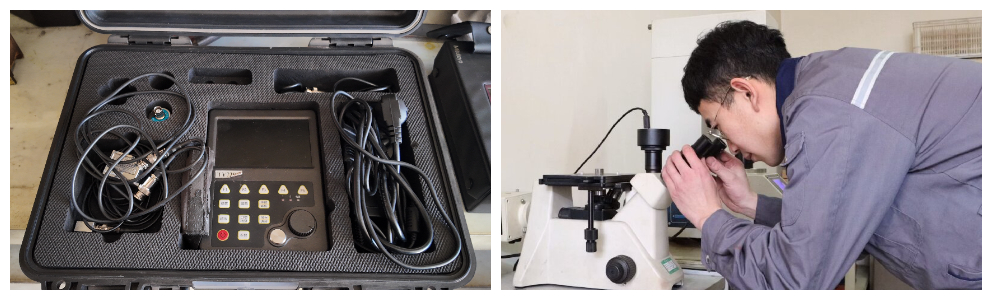

Raw materials are “the first threshold of product quality, and Shandong Lutong Heavy Industry imposes almost uncompromising control standards on them. When a batch of high-quality steel for the production of backhoe loader axle housings arrives at the shop, a quality control engineer immediately approaches with a handheld spectrometer in hand, precisely aiming the probe at the surface of the steel. Data about the contents of various elements instantly appears on the screen. Each batch of raw materials undergoes a full spectrometer inspection to ensure that the content of carbon, manganese, chromium and other elements fully meets design requirements, providing the high strength and toughness required for the drive axle at the root level, explains a quality control engineer as he records the data.

During the processing stage, monitoring the quality of welding and the internal characteristics of components is equally important. Blue sparks fly in the welding shop, technical personnel strictly monitor the parameters of welding current, voltage, etc., and ultrasonic inspection equipment, like a “sharp eye,” immediately conducts a comprehensive flaw detection of each weld, identifying even microscopic cracks and pores, to ensure that the weld strength perfectly matches the base material. In addition to hardness testing, the technical team also uses a metallographic detector to take an in-depth look at the internal microscopic characteristics of the components. This precision equipment acts as a magnifying glass to the microscopic world, capable of clearly depicting the shape and grain distribution of a metallic material, as well as its internal structure. Using a metallographic detector, technicians can accurately determine whether structural defects exist in the material of a component, ensuring the uniformity and stability of its internal structure, thereby ensuring the mechanical properties of the components meet the high load and impact resistance requirements of the drive axle, and laying a solid foundation for its long-term stable operation at the structural level.

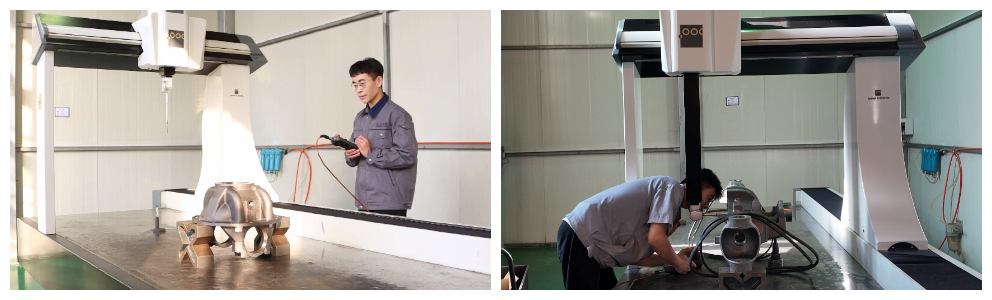

Machining precision directly affects the assembly accuracy and transmission efficiency of the drive axle. Shandong Lutong Heavy Industry has no hesitation in introducing the world's best three-axis hex test equipment to take micron-level measurements of key components such as drive axle housing, gears and axle shafts with an accuracy of 0.001mm. Inspectors operate the equipment, the probe moves smoothly on the surface of the parts, and the dimensional data is transmitted in real time. accurate down to the smallest detail; Combined with a surface finish tester, carefully check the surface smoothness of the parts to ensure that all parts can fit together exactly. a solid base for subsequent assembly.

If precise control is a line of quality assurance, then strict technological regulations and quantitative management are a quality stabilizer. In key assembly processes, technicians strictly follow standardized operating procedures: adjusting bearing preload using a special torque wrench, closely monitoring the readings to ensure smooth bearing operation and stable load; Using precision tools, it repeatedly calibrates the meshing area and gap between gear teeth, ensuring smooth and efficient transmission, minimizing noise and energy loss. For products that frequently operate under heavy load and high intensity conditions, such as telehandler axles and backhoe loader axles, the accuracy of control at this stage directly determines the life of the equipment and its stability,” says the assembly team leader.

During the torque control phase, high-precision torque meters are constantly on watch, checking every fastening point: every bolt, every transmission connection. Data is transmitted in real time, eliminating component loosening due to insufficient torque or damage from overload. And before the finished product is released, an even more rigorous final test occurs: technicians place the drive axle on a test bench simulating real-life operating conditions, conduct long-term bench tests, constantly monitoring key data such as speed, torque, temperature rise, to ensure consistent product performance under high-intensity work; A leak test is then carried out, carefully monitoring pressure changes using professional equipment to fully identify potential seal problems and eliminate leaks. Only after successfully passing these two key tests and confirming the absence of any hidden defects, the drive axle receives a certificate for shipment from the factory.

Quality is the lifeline of an enterprise. The release of each drive axle carries our responsibility and commitment to customers, and this is our key competitiveness in the industry,” the responsible representative of Shandong Lutong Heavy Industry firmly states when talking about the quality control philosophy. Since its establishment, the company has always adhered to the spirit of craftsmanship, meticulous processing and continuous improvement, constantly investing resources in R&D to optimize the quality control system, integrating advanced international inspection technology with local technological expertise to ensure that each drive axle combines reliability and durability. Whether it is drive axles for mining equipment adapted to the harsh conditions of mines, drive axles for agricultural equipment that cope with a variety of field conditions, or axles for telehandlers and backhoe loader axles for logistics and construction, all of them, thanks to their excellent quality, precisely meet customer needs, providing global partners with safe and reliable power transmission solutions, winning widespread recognition and appreciation.

From the strict selection of raw materials to the precise control of the processing stages, from the careful management of the assembly process to the rigorous testing before release, Shandong Lutong Heavy Industry demonstrates the responsibility for quality in China's heavy machinery industry with its craftsmanship at all stages. In the future, the company will continue to in-depth work in the field of quality control, constantly introducing advanced inspection technology and management concepts, continuously enhancing the core competitiveness of products, expanding the global development capabilities of construction, agricultural and mining machinery with even higher quality drive axle products, demonstrating the powerful strength of China's intelligent manufacturing.