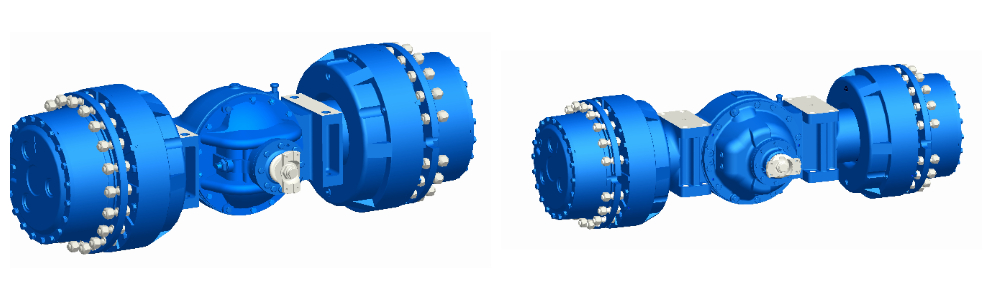

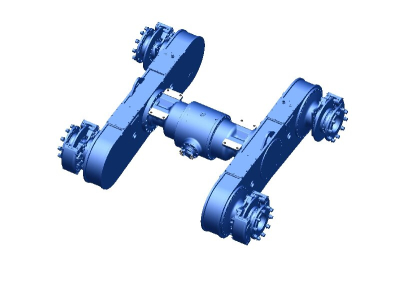

The drive axle of Shandong Lutong CY series underground scrapers is the benchmark for mining equipment quality.

Recently, Shandong Lutong Heavy Industry Machinery Co., Ltd.(hereinafter referred to as “Shandong Lutong”), the leading axle of CY series underground scrapers was officially launched in the international market, which attracted wide attention in the mining equipment industry.As a leading enterprise in the R&D and production of drive axles for more than 30 years, Shandong Lutong relies on a deep understanding of the working conditions in the mining industry and the accumulation of core technologies to introduce high-performance mining drive axle production technology into the CY series products, integrating a series of industry-leading core components.configurations and strict quality control throughout the entire process enable the creation of efficient, safe and reliable equipment solutions adapted to challenging underground conditions, which not only further enhances the company's range of mining equipment, but also demonstrates the technical confidence and quality of Chinese mining equipment companies with strong production capabilities.

The global mining industry is currently transforming to become smarter, more efficient and safer. The performance of underground mining equipment, which is a key link in mining, directly determines the mining efficiency and operating safety. The conditions of underground mining are naturally difficult and harsh: the narrow space on the roadway makes it difficult to operate and pass the equipment, and prolonged exposure to wet and dusty road surfaces can easily lead to vehicle slippage and component wear. Continuous, high-intensity operation places stringent demands on the equipment's lifting capacity. At the same time, thus, the safety of equipment braking and the difficulty of troubleshooting in confined spaces have significantly increased. In such difficult operating conditions, the driving axle of the downhole scraper serves as the “heart” and “strong point” of the equipment. Transmission efficiency, anti-slip performance, braking reliability and environmental adaptability directly determine the efficiency, stability and service life of the entire equipment. machine, and this indicator has become the main indicator of the competitiveness of downhole pig products.

Shandong Lutong has been active in the field of drive axles for many years. Relying on continuous scientific and technical research on working conditions in the mining industry, Shandong Lutong has accumulated rich technical experience and a large number of independent patent achievements in the research, development and production of drive axles for mining machinery. Based on this core technical advantage, the company deeply integrates the R&D experience of drive axle with the design of the whole underground scraper machine, and achieves precise results in solving the major problems associated with underground mining, and finally creates drive axles borehole scrapers of the CY series. Their drive axles are fully upgraded in key areas such as power transmission, anti-skid braking and environmental adaptation, precisely meeting the demanding requirements of underground mining and providing mining companies with a new choice to solve industry problems associated with low operating efficiency, multiple equipment failures and high safety risks.

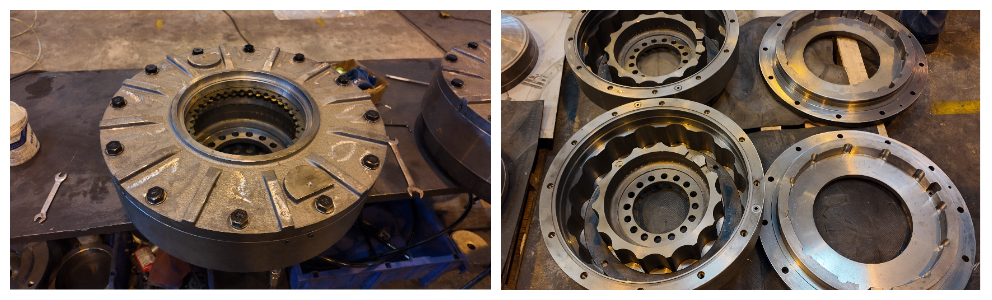

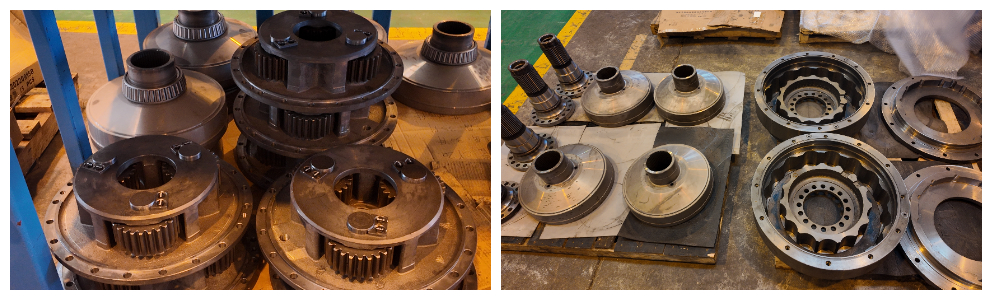

In terms of main power transmission and anti-slip performance, the drive axle of CY series underground scrapers is equipped with the industry's best anti-slip differential. This basic configuration fundamentally solves the problem of slipping on wet and muddy roads underground, and has become a key support to ensure continuous operation of the equipment. According to Shandong Lutong technical team, the No-spin anti-slip differential is equipped with an advanced mechanical lock, which achieves 100% automatic locking, and can accurately respond to difficult road conditions without manual intervention. When the vehicle enters a muddy road section or uneven roadway with When one wheel slips, the differential can instantly complete locking, accurately transferring all power and torque to the locked wheels, even in the extreme case of single-sided wheels hanging in the air. however, it allows the vehicle to have enough traction to continue moving, completely eliminating the problem of interruption caused by slippage of traditional scrapers.

Compared to traditional differentials, non-slip differentials also offer significant advantages of being maintenance-free. Its internal structure has been precisely optimized without the need to add special lubricants, and without regular disassembly and adjustment. It can adapt to the needs of long-term continuous underground operations, which significantly reduces maintenance costs and equipment downtime. Overhaul Time: Taking a large underground mine as an example, when traditional scrapers operate on wet and dry roads, the average monthly downtime caused by failures due to slippage is 8-10 hours, and CY series products equipped with anti-slip differential can reduce such failures and downtime to less than 1 hour, and the continuity of work volume is increased by more than 80%, which greatly improves the mining efficiency of the mine. The application of this core technology allows the CY series products to have excellent maneuverability and stability in difficult road conditions, and has become an important guarantee for increasing production capacity for mining enterprises.

Safety is the main prerequisite for underground work, and is also the main factor taken into account by Shandong Lutong during the research and development of the drive axle of CY series underground scrapers. To fully ensure the safety of underground work, Shandong Lutong is equipped with a spring brake Positionstop-hydraulic wet brake with release for CY series products. The brake adopts an integrated design that integrates the functions of the driving brake and the parking brake, providing effective protection of “one device, two uses”, and completely solves the problem of the complex structure and multiple failure points of the traditional scraper brake system.

High humidity, turbid water and heavy dust, which are common in underground operating conditions, are one of the main reasons for the failure of the scraper drive axle. Considering this main problem, the drive axle of CY series borehole scrapers is specially equipped with a wheel-side floating oil seal to create an effective and reliable seal protection system, which greatly improves the product's adaptability to wet and dry operating conditions. The wheel-side floating oil seal consists of two floating rings. with carbide sealing surfaces and elastic elements. By preloading the elastic elements, the two sealing surfaces are tightly connected, forming a double seal protection, which can effectively prevent impurities such as dirt, dust and ash from entering the transmission mechanism from the wheel side, and avoid the wear and stagnation of key transmission components such as gears and bearings due to the penetration of impurities caused by the root cause. Failures such as wear and stagnation caused by the penetration of impurities.

Shandong Lutong has undergone extensive testing and verification under simulated operating conditions. The drive axle of a downhole scraper equipped with a sealed structure was continuously simulated for 3000 hours in a wet and dry environment. The wear of wheel drive components is only 15% of that of traditional sealed design, and the wear of drive wheel rims is the drive axle failure rate is reduced by more than 60% year on year. Even under extreme operating conditions, long-term humidity and dust, the drive axle can maintain excellent transmission efficiency, effectively reduce equipment downtime and maintenance, and greatly reduce the operation and maintenance costs in mining operations enterprises. The application of this design solution fully reflects Shandong Lutong's user-oriented research and development concept, and accurately solves the problems associated with the use of equipment in mining enterprises in difficult environments.

The stability and reliability of product quality is ensured by strict inspection of every detail. Shandong Lutong has always adhered to the principle of “quality first” in the entire process of research and development and production of the CY series underground scraper drive axle, from the selection of parts to the structure design, production and processing, every link is subject to strict quality standards. When selecting the main components, the company insists on choosing products from world famous brands to ensure the reliability and service life of the products from the manufacturer. Whether it is the main gears of the drive axle, high-precision bearings or key hydraulic system valve groups and seals, they have undergone rigorous supplier selection, sample testing, batch inspection and other audit steps to ensure each component meets international mining equipment industry standards. Eliminates the root cause of equipment failures caused by parts quality issues.

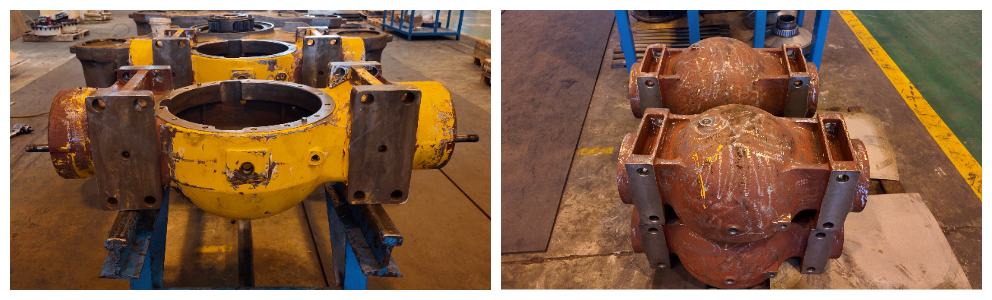

At the structural level, the drive axle of the CY series underground scrapers is made in the form of a cast steel jumper. Compared with the traditional welded bridge, the general cast steel bridge is formed by one-time pouring, which avoids the formation of pores, cracks and other defects generated during welding processing, and has greater rigidity and impact resistance. Professional test data shows that the impact strength of the cast steel bridge structure is generally more than 40% higher than that of the welded bridge structure, and it can easily cope with high-intensity impacts such as impacts stones and road unevenness, which often arise during underground work, which significantly extends the life of the bridge. driving axle. At the same time, a two-stage transmission with retarding is installed on the driving axle. The design was precisely calculated and optimized by Shandong Lutong's technical team. The transmission efficiency is stable in the excellent range of 92-95%, which ensures high power output while minimizing energy loss and achieving high performance efficiency and energy-saving operation.

The successful launch of the CY series underground scraper drive axle is not only an important expansion of Shandong Lutong's product range, but also a concentrated embodiment of the company's manufacturing strength, technical research and development capabilities, and quality control level. To ensure that product quality is always at the highest level in the industry, Shandong Lutong has implemented a three-dimensional quality control system covering the entire process of R&D, production, testing and leaving the factory, forming a quality assurance model throughout the chain “pre-prevention, incident control and follow-up”.

In the context of the intelligent transformation of the global mining industry, Shandong Lutong will continue to focus on market demand, using technological innovation as the basis, continue to deepen the research and development of drive axle technology, continuously optimize product performance, and expand the range of mining equipment. In the future, the company plans to continue integrating smart technologies based on the drive axle of CY series downhole scrapers, develop intelligent downhole scrapers with remote monitoring, early warning of faults, automatic navigation and other functions, and promote the development of mining equipment in a more efficient, safe and smart direction. At the same time, the company will continue to improve its global service network, improve the response speed of overseas services, provide better equipment and services to the global mining industry, help mining enterprises reduce costs and improve efficiency, ensure safe and environmentally friendly mining, and promote the mining equipment industry to high-quality development.