Overcoming the "Invisible Summit": the birth of the first domestic tandem bridges.

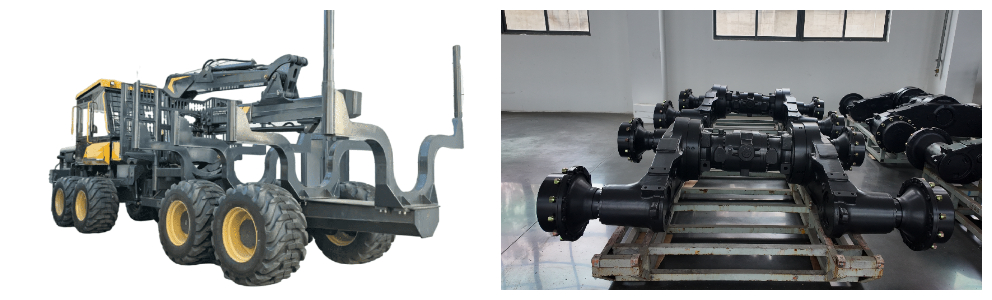

In the forestry machinery industry, forestry machines have always been the “invisible pinnacle” in the localization process due to their high-tech equipment and high-added value characteristics.For a long time, most of the logging equipment on the Chinese market was imported or modified with excavators.The core technology of special forestry machines - especially the drive axle system adapted to extreme mountain conditions - has always been an obstacle that domestic manufacturers have been unable to overcome.However, this situation is gradually being disrupted.Shandong Lutong, relying on more than 30 years of drive axle experience, after years of research, development and testing, successfully launched China's first high-performance drive axle designed for forestry machines, and not only achieved a breakthrough in the localization of key components, but also won close attention and orders from domestic and foreign equipment manufacturers for its excellent sealing performance, reliability and difficult terrain maneuverability.In this article, we will take a look at the production site to analyze in detail the entire process of creating this drive axle, from drawing to load testing, and demonstrate the serious steps taken in China in the field of high-quality transmission components.

1. Problems in unpopular areas: Why is it so difficult to manufacture the drive axle of a logging machine?

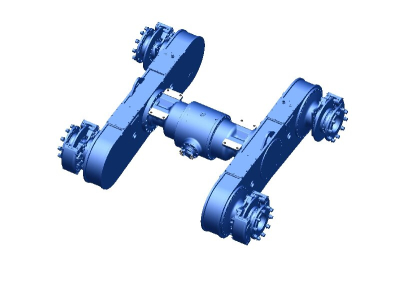

Forestry machines are not a category of equipment that is familiar to the general public. In China, due to the complex technology of the front hydraulic working device and chassis transmission system, as well as the high price of the vehicle, coupled with the fact that the country's terrain is mainly mountainous, the application of traditional large-scale forestry equipment is limited, so the product market has long been dominated by foreign brands, and it is a typical "unpopular" high-end equipment. However, unpopularity does not mean lack of demand. As As domestic equipment manufacturers accelerate their expansion into overseas markets, the demand for specialized equipment suitable for areas rich in forest resources such as Northern Europe, Russia and North America is becoming increasingly prominent. The operating conditions of forestry machines are often extremely harsh: rugged mountains, wet and slushy forested areas, as well as continuous heavy-load logging operations put the power, maneuverability, integrity and reliability of the entire machine to the test. Among them, the drive axle is The main component of the chassis that supports the vehicle's weight, transmits torque, and provides steering and braking. Its characteristics directly determine the vehicle's survivability under extreme operating conditions. A poor seal can allow dirt to enter and accelerate the wear of gears and bearings; insufficient rigidity or unreasonable design can easily lead to structural damage or instability of the vehicle on difficult roads; if the braking performance is not reliable enough, it directly threatens the safety of operators. Thanks to this, a special drive axle capable of working in mountain logging environments has become a technical fortress that domestic equipment manufacturers have to overcome to advance in this segment. It was after Shandong Lutong got an idea of the potential market demand and technical shortcomings that it decisively embarked on an independent research project to develop tandem axles.

2. The path to hard work: 30 years of experience has enabled us to solve design and technological process problems.

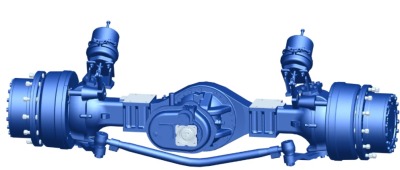

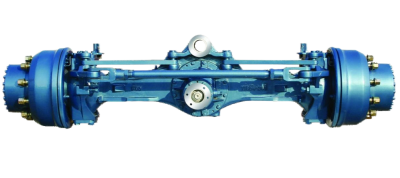

At the beginning of research and development, Shandong Lutong's technical team clearly realized that simply copying the design design of the traditional drive axle of construction machinery would not work. They systematically studied the design designs of similar advanced products at home and abroad, and conducted many in-depth studies on the working conditions of manufacturing factories and potential production sites to understand the actual operating cycle and load spectrum of forestry machines. Based on more than 30 years of experience in the design and production of leading bridges, the team focused on several key aspects: adaptability to extreme terrain conditions, efficient and reliable transmission system, and long-term seal protection. First of all, the rotary balancer design was innovatively applied in the design of the bridge structure. This design is not a simple simulation, but has undergone careful mechanical calculations and simulation analysis. The balancer can make the left and right wheels independently rise and fall on uneven ground, increasing the area tire grounding. Even in mountainous areas with extremely steep slopes, multiple tires can always maintain effective contact with the ground, provide sufficient traction, and greatly improve the stability and rollover ability of the entire machine. More importantly, the team has developed a scientifically proven deviation between the input center and the output center of the weight unit. Such detailed development ensures that when the vehicle passes on uneven roads and obstacles, the movement of the axle body becomes smoother, traffic disturbance is reduced and the movement is greatly improved permeability.

Secondly, the transmission uses all high-precision gears and planetary gears. The gears, axle shafts and other transmission components are subjected to carburizing, hardening, precision grinding and other processes to ensure tooth surface hardness, contact accuracy and transmission stability. The internal transmission path has been optimized to minimize power transmission losses, improve efficiency, reduce noise and extend service life.

In the harsh environment of water, dust and corrosive environments in mountainous forest areas, the sealing performance has been improved to an unprecedented strategic level. The drive axle is equipped with multi-channel composite sealing structure in all key parts, such as the wheel side, the connecting surface of the main gearbox and the rocker joint. The sealing material selection takes into account characteristics such as oil resistance, high and low temperature resistance, wear resistance and protection against aging, and strict sealing controls are carried out during the assembly process to ensure that every gap is securely sealed and that external contaminants are prevented from entering.

Additionally, as an important safety guarantee, this drive axle is equipped as standard with wet multi-disc brakes. Compared to traditional dry brakes, wet brakes are completely immersed in cooling oil, providing excellent heat dissipation and high resistance to thermal decay. They are especially suitable for long-term braking of forestry aircraft on downhill heavy loads, and their braking performance is stable and reliable. At the same time, the cross-axle differential lock is designed so that when one side of the wheel slips, the differential speed can be quickly locked, and the power is transferred to the attached wheel, which helps the vehicle to easily get out of the predicament.

3. From the Lab to Lin Hai: Rigorous Testing Ensures Reliable Quality

Passing the bench test is only the first step in product verification. Shandong Lutong knows that the real test lies in practical application. Therefore, the technical team actively sought partners and sent the first batch of drive axle samples that were successfully produced on a pilot basis to authoritative institutions such as the National Construction Machinery Quality Inspection Center, and also carried out more systematic and standardized mandatory bench tests. The test is carried out in strict accordance with national standards and the most stringent industry specifications and comprehensively evaluates axle body fatigue strength in vertical bending, axle static torsional strength, gear fatigue life, and overall brake performance. Once the test report was stamped “qualified,” the team gained initial confidence.

However, “on paper, I finally feel small.” In order to obtain the most realistic operating condition data, the company does not hesitate to send products to equipment manufacturers for loading and testing on site. In typical forest conditions such as cold regions in the northeast and mountains in the southwest, a prototype equipped with the drive axle of a Shandong Lutong forestry machine began six months of testing under extreme operating conditions. The test program included: long climbs in difficult conditions, fording through swamps, fast travel through rough logging sites, continuous cyclic operations of picking and cutting wood... Testers recorded oil temperature, leakage, braking response, gearbox noise and other characteristics of the drive axle under various extreme conditions. During this period, a team of engineers was on the scene, who could monitor the data at any time and quickly analyze and correct minor problems. After six months of wind and rain, and six months of extreme loads, the drive axle passed the test, and its reliability, durability and environmental friendliness were finally praised by the OEM test team. It was this test report, based on real-life scenarios, that paved the way for the products to be listed en masse.

4. Market Developments and Future Prospects: A New Benchmark for Domestic Core Components

The rigorous R&D approach, reliable production technology and testing process that can be called “self-isolation” have collectively formed the market competitiveness of Shandong Lutong forest machine drive axle. When the product was officially introduced into the market, it quickly attracted attention in the industry. Above all, it has overcome the long-term dependence on imported or modified drive axles in this field, and proved that domestic companies are quite capable of overcoming technical barriers associated with high-quality transmission components. Secondly, Shandong Lutong's pragmatic style based on the principle of "inspect first, then promote" has greatly strengthened the confidence of equipment manufacturers. What they see is not only the product, but also a complete and reliable technical solution and quality assurance system. At present, Shandong Lutong has successfully carried out stable supply of small batches of products to Jining Jiubang and other domestic manufacturers who are leading the development of logging industry technology, and their products have proven themselves well in practical use. What is even more interesting is that new cooperative manufacturers are coming into contact with production, which indicates a steady increase in popularity in the market. Moreover, access to the international market has been opened. After a detailed assessment of the product's technical information and test reports, Russian customers clearly expressed their intention to cooperate. They are currently awaiting download and testing of a bridge prototype, which has laid a solid foundation for further development. The company's products are sent to sea.

The production process diagram of Tandem axles not only reflects the product creation process, but also reflects the long-term spirit of a Chinese manufacturing company that strives for technological innovation, deep penetration of market segments and ensuring its reliability. In the face of global competition and the establishment of an independent and controlled production chain, Shandong Lutong's breakthrough in the “unpopular” direction of producing forestry machine drive axles has an important demonstration value. This shows that in countless fields of technology, Chinese production is gradually evolving from secondary to parallel and even leading. In the future, Shandong Lutong will continue to use the drive axle as the basis, continue to invest in research and development,

In the future, Shandong Lutong will continue to use the drive axle as the basis, continue to invest in research and development, deepen cooperation with equipment manufacturers, and optimize the performance of logging products in different regions and tree species, and explore the application of intelligent and electric drives in forestry machinery. This drive axle, shipped from the Linhai precision workshop to all over the world, carries not only the power of the machine, but also the strong belief in the breakthrough of China's high-quality equipment manufacturing industry.