Shandong Lutong has added a new manual cleaning line, refined, which improves the quality of the drive axle.

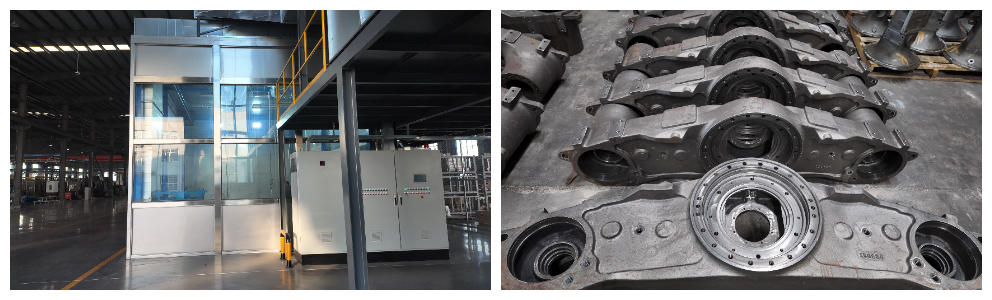

Recently, Shandong Shandong Lutong Machinery Co., Ltd.(hereinafter referred to as “Shandong Lutong”) officially completed the commissioning of a brand new manual cleaning line.The cleaning line is specially designed for the main drive axle components, and is completely suitable for cleaning the casting parts of construction machinery drive axle, agricultural machinery drive axle and mining machinery drive axle.This production line upgrade not only further improves the entire production chain and processing system of Shandong Lutong drive axle products, but also ensures precise cleaning of the entire casting process of parts from entering the factory to painting, which ensures reliable protection of product quality from the very beginning and provides customers around the world with high quality.with more stable and reliable solutions for the main components of the drive axle, demonstrating the company's development concept aimed at improving the quality and excellence in the production of drive axles.

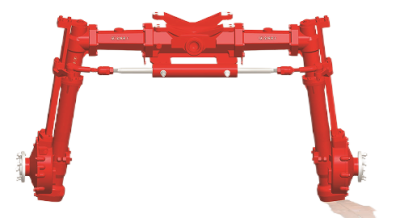

In construction machinery, agricultural machinery and mining, the drive axle is the “conductive power core element” of the equipment, and its quality and stability directly determine the operating efficiency, safety performance and service life of the entire machine. For products used in harsh operating conditions, such as forklift drive axles, they have long been subjected to high-intensity testing, shaking, and dusty and humid environments, which place extremely high demands on surface precision, sealing performance and corrosion resistance. durability of the main components. As a professional enterprise that has been actively engaged in the research, development and production of drive axles for more than 30 years, Shandong Lutong has always adhered to the principle of “quality enterprise” as the core development strategy. Through strict control of product details, the company has won a good reputation in the global market. Construction machinery drive axles, loaders and other products are exported to Russia, Belarus, Iran and other countries and regions, becoming the preferred auxiliary supplier for many foreign machinery manufacturers.

This time, the new refined manual polishing line is an important measure to upgrade and deepen the quality control of Shandong Lutong based on market demand. Compared with the fully automatic polishing line, although the manual polishing mode places higher demands on the professional skills of operators, it has irreplaceable advantages in cleaning precision, covering hard-to-reach areas and customization. To ensure the cleaning efficiency, Shandong Lutong has not only developed a standardized refined process line, clarified the performance characteristics and quality standards of each link, but also conducted systematic training for operators before starting work, which covered the design characteristics of the main components of the drive axle, as well as the main points of the cleaning process, quality control standards and other parameters, ensuring that each operator can accurately control the intensity and accuracy of polishing and achieve the operation goal of “thorough cleaning with zero dead angle coverage.”

According to the head of Shandong Lutong's production technology department, the cleaning process of drive axle casting parts passes through key production and processing units. The new cleaning line provides a complete cycle of this process. Specifically, when the main casting parts of the drive axle, such as the axle housing, axle arm, main gear housing, differential housing, etc., leave the foundry and enter the processing workshop, they first enter the coarse cleaning section of the cleaning line. The main purpose of this connection is to remove protruding rust from the surface of the cast parts, roughness and sand residues generated during transportation, and also eliminate obstacles to subsequent more thorough processing. Operators rely on their professional judgment to select the appropriate grinding tool based on the structural characteristics of various castings, which not only completely removes surface contamination, but also avoids damage to the casting body and fully guarantees the structural integrity of the casting.

After completion of coarse cleaning and preliminary quality control, the cast parts enter the main part of the cleaning line - the fine grinding stage. This stage is key to ensuring the precision of drive axle manufacturing. It mainly clears the surface of burrs, raised edges and contaminants around the grinding holes that are left behind after early machining of the casting. It is worth noting that the axle housing, main gear housing and other drive axle parts have more complex designs of cavities and connecting holes. If the burrs and contaminants on these parts are not completely removed, they will directly affect the accuracy of subsequent assembly, resulting in abnormal mating clearances between parts, which in turn cause increased noise, increased wear and other malfunctions, seriously affecting the stability of the drive axle.

Shandong Lutong operators will use special fine grinding tools to deeply penetrate into various chambers and holes of castings for spot cleaning, and undergo a two-factor inspection method of “visual inspection + hand touch” to ensure that the error in the surface flatness of castings is controlled within the acceptable range. a number of leading industry standards. Using the forklift axle housing as an example, extremely high surface precision is required to connect the parts to the internal shaft bore. The operator needs to re-polish and inspect to ensure that there are no burrs around the bore and ensure precise interaction between the downstream drive shaft and the housing axle, thereby improving the power transmission efficiency and smooth operation of the loader drive axle.

In addition to rough cleaning and fine polishing, the cleaning line also performs surface pre-treatment before painting. This directly affects the appearance, texture and corrosion resistance of drive axle products. Since the cast parts will retain some of the original paint and oxide layer during the casting process, if new paint is directly applied, this will cause the new paint to not adhere firmly to the surface of the casting, and problems such as chipping and peeling will occur, which will greatly reduce the service life of the casting. to this end, the cleaning line operators will use professional polishing technology to completely remove the original paint, oxide layer, oil, dust and other contaminants from the surface of the castings, so that the surface of the castings will have a uniform rough surface. This processing method can not only greatly improve the adhesion of new paint, but also improve the wear resistance and corrosion resistance of the paint film, ensuring that the drive axle retains good appearance and protective properties when long-term use in harsh environments such as open air, dust and humidity.

To further strengthen quality control, Shandong Lutong has also established many quality control points at all stages of cleaning product production. Every time the cleaning process is completed, quality inspectors conduct a comprehensive inspection of the castings according to strict quality standards, including surface finish, flatness, hole placement accuracy and other indicators. Only those castings that meet the standards can be sent to the next stage of production. This dual quality control system of "process control + final inspection" ensures that every product leaving the factory meets quality requirements, and also allows Shandong Lutong construction machinery drive axles, forklift drive axles and other products to form an undeniable quality advantage in the market.

The launch and commissioning of the manual cleaning line is an important milestone for Shandong Lutong in promoting the consistent upgrading of production technology, and a clear embodiment of the company's concept of “quality first, customer first.” For a long time, Shandong Lutong has been focusing on technological research and development and technological innovation in the field of drive axles. With a deep understanding of the needs of the industry, Shandong Lutong has continuously optimized production processes and improved product quality. The company's product range covers many categories, such as construction machinery drive axles, loader drive axles, agricultural machinery drive axles and mining machinery drive axles, which can meet the individual needs of various industries and different working conditions. With a reliable production system and strict quality control, Shandong Lutong's drive axle products have not only received wide recognition in the industry domestic market, but also successfully entered foreign markets and established long-term stable cooperative relationships with equipment manufacturers in many countries.

Looking into the future, Shandong Lutong will continue to focus on market demand, focusing on improving quality, and continue to promote consistent upgrading of production processes and technological innovation. Based on the existing cleaning line, the company plans to further optimize the working process, introduce more advanced grinding tools and inspection equipment, and continuously improve cleaning efficiency and accuracy; at the same time, it will increase investment in the research and development of drive axle core technology, continuously improve the performance and intelligence level of the product, and provide more valuable drive axle solutions to customers around the world. Shandong Lutong's responsible officer stated that the company will always adhere to the original intention of “ensuring quality, innovation and development”, control the entire production process to more stringent standards, and regain the trust and support of customers around the world with better products and services. In the future, Shandong Lutong will continue to expand its drive axle manufacturing field and strive to become the world's leading supplier of drive axle core components, as well as contribute to promoting high-quality developments in the fields of construction machinery, agricultural machinery and mining.