What is a truck axle?

In the control system of commercial vehicles such as trucks, the truck axle is a major component that performs many key tasks such as carrying, driving, steering and braking, and is known as the “bone support” and “power transmission center” of the vehicle.Simply put, a truck axle is the central axis that connects the wheels and transmits power.Its functions cover the entire process of driving the vehicle: all kinds of loads occurring during the movement of the vehicle, including body weight, cargo weight, impact force, braking force, etc., should be distributed evenly to the wheels through the axle, and then transferred to the ground, to avoid damage to the vehicle caused by excessive local force; At the same time, the axle also needs to cooperate with the steering system to achieve flexible control of the vehicle's moving direction, and the joint braking system accurately transmits braking force to the wheels to ensure driving safety.It is worth noting that the performance requirements of truck axles in different operating scenarios vary significantly: truck axles for long-distance logistics must be light and smooth to reduce fuel consumption and driving fatigue; while truck axles in the engineering and mining industries must have increased structural strength and wear resistance to cope with the loads.with severe testing in difficult road conditions.It can be said that axle characteristics directly determine the handling stability, driving safety and operating efficiency of the vehicle and are an important component of the competitiveness of commercial vehicles.

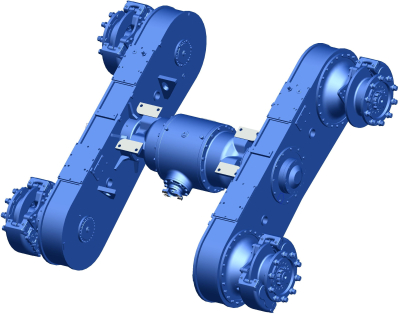

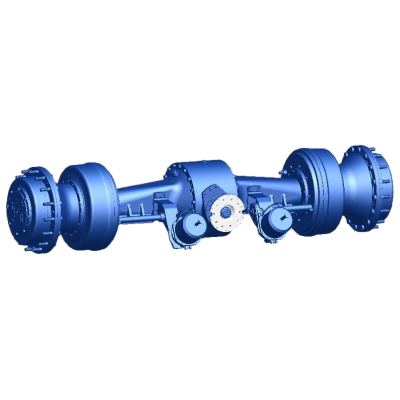

Based on functional differences, truck axles can be divided into several categories, such as drive axles, steering axles, and support axles. Among them, drive axles are the most widely used in severe operating conditions due to their power transmission functions. As a key device for transmitting engine power to the wheels after braking and torsion, the drive axle integrates major components such as main gearbox, differential and axle. Its technical level directly determines the traction characteristics and load limit of the vehicle - the transmission efficiency of the main gearbox affects the power loss, and the design of the differential ensures differential operation of the wheels when turning the vehicle, and the strength of the axle determines the stability of power transmission. Especially for construction equipment, agricultural equipment and mining equipment, which often operate under high load, high traffic intensity and difficult road conditions, the reliability of the drive axle is the main condition for ensuring long-term stable operation of the equipment. If Take the mining industry for example, the roads in the mining area on which mining trucks drive are mostly rough dirt roads, and some areas still encounter obstacles such as sharp rocks and deep holes, and they have to transport hundreds of tons of ore for a long time. The drive axle of a mining dump truck must have three main advantages: first, it has high impact resistance, which can withstand instantaneous impacts caused by road unevenness and rocks; Secondly, it has excellent wear resistance and can resist wear and erosion of internal components due to dust and gravel; Third, it has ultra-high load capacity to meet the strength requirements of heavy load transportation. If the performance of a mining dump truck's drive axle does not meet the standards, it is highly susceptible to problems such as axle failure and differential failure, which will lead to work interruption and huge economic loss for mining companies.

When it comes to highly reliable drive axles customized for special vehicles, Shandong Lutong, a professional drive axle manufacturer, has become the reliable partner of many companies at home and abroad. Since its establishment, Shandong Lutong has always focused on the research and development, production and sales of drive axles. With a deep understanding of various operating scenarios, Shandong Lutong has created a drive axle product system covering a full range of categories, which can be perfectly adapted to construction machinery (eg excavators, loaders, cranes), agricultural machinery (eg tractors, combine harvesters, seeders), mining machinery (eg quarry trucks, quarry loaders) and many others. Among them, independently developed mining dump truck drive axles have won wide popularity in the mining market at home and abroad due to their superior performance.

Shandong Lutong's core competitiveness comes from the perfect technological research and development system and strict quality control standards throughout the entire process. In order to provide advanced production technology, the company has formed a professional R&D team led by leading industry experts, who account for more than 15% of the R&D personnel, many of whom have more than 20 years of drive axle R&D experience as core technical personnel. The company annually invests 12% of its revenue into technology research and development, has established a drive axle design R&D center, equipped with advanced simulation laboratories, fatigue testing laboratories and other R&D platforms, and has successfully introduced a number of key technologies. In the production process, the company has introduced imported CNC machines, automated welding production lines and intelligent technological assembly lines, to ensure the automation of the entire process from parts processing to finished product assembly - CNC machining precision can reach 0.001 mm to ensure adaptability of the main components; Automated welding production line uses robotic welding technology, which increases the uniformity of weld strength by 30%, which avoids fluctuations in the quality of manual welding; The intelligent technological assembly line is equipped with an online inspection system to monitor the assembly accuracy in real time. The application of this series of advanced equipment not only improves the productivity of the drive axle, but also effectively guarantees the consistent manufacturing accuracy of products. At the same time, the company has implemented a comprehensive quality control system covering raw material purchasing, production and processing, and finished product testing. All raw materials are sourced from renowned suppliers at home and abroad. Before entering the market, they must undergo 8 testing processes, such as material inspection analysis and mechanical property testing; Finished products must pass 16 strict tests, such as static load test, fatigue test, leak test, and high and low ambient temperature tests. Among them, the drive axle of mining dump trucks also needs to undergo an additional 1000 hours of heavy-duty simulation testing to ensure reliability under extreme operating conditions, and the product transmittance rate reaches 99.8%. With superior quality, the company's products have passed ISO 9001 international quality system certification, and the service life is 20% higher than the industry average, which can effectively reduce customers' equipment maintenance costs and downtime losses.

With the acceleration of global economic integration, Shandong Lutong has been actively exploring the international market, relying on high-quality products and a perfect foreign trade service system, steadily increasing its share in the global market. Currently, the company's drive axle products are exported to Russia, Belarus, Iran and other regions and countries. Shandong Lutong's foreign trade team has conducted in-depth study tours to the mining area to optimize the load-bearing structure and sealing of the drive axle. bridge.In order to better serve customers around the world, the company has formed a professional foreign trade service team. The team members have rich experience in foreign trade and are fluent in multilingual communication skills, and respond to customers' product inquiries and technical issues in a timely manner. According to the market needs of different countries and regions, the company can also provide customized product solutions, from product design, research and development, to production and supply. The entire process is accompanied by a special project manager who monitors the implementation of the plan. In the field of logistics and transportation, the company has established long-term cooperation with well-known logistics companies. For heavy-duty products such as mining truck drive axles, the company also offers customized packaging solutions using solid wood pallets + impact-resistant cushioning materials to reduce the risk of damage during transportation and ensure safety. safe and efficient delivery of goods. The average delivery cycle of foreign trade orders is short, and the on-time delivery rate reaches 98%. In addition, the company has established a global after-sales service network, equipped with professional after-sales technical personnel and sufficient spare parts inventory, which can quickly respond to customers' after-sales service needs, provide customers with on-site technical service, technical guidance, spare parts replacement and other comprehensive services, and completely solve the after-sales service problems of overseas customers.

Currently, the global construction machinery, agricultural machinery and mining machinery industries are developing towards the creation of large-scale, intelligent and efficient machines. The market demand for high performance mechanical parts is increasing day by day. The quality and reliability of truck axles have become key indicators to evaluate the competitiveness of machinery products. In this context, Shandong Lutong has always adhered to the business philosophy of “quality-oriented, innovative and customer-first”, and has continuously improved the research and development level of drive axles and production, optimized the product structure and improved the service system. The company follows the development trends of the industry and is actively engaged in the research and development of intelligent drive axles. A project to develop an articulated drive axle for trucks has now been launched. At the same time, the company continues to expand the application scenarios of its products and in response to the development needs of new energy mining trucks, it is developing drive axle products adapted to new energy power systems to optimize transmission efficiency, reduce energy consumption and contribute to the green transformation of the industry. Whether it is a high-strength drive axle adapted for engineering construction, an efficient drive axle for agricultural production or the weather-resistant drive axle of a mining dump truck, Shandong Lutong can precisely meet customers' individual needs and provide customers around the world with more efficient and durable solutions. reliable drive axle solutions. With solid technical base, excellent product quality and perfect service in foreign trade, Shandong Lutong has gradually become a global leader in the drive axle field, helping domestic and foreign customers improve operating efficiency and maximize economic benefits.

If you want to know more about the products of drive axles, truck axles and drive axles for mining dump trucks, or have an intention to cooperate, please contact Shandong Lutong via message board or private message. We will respond to your inquiries as soon as possible, provide you with detailed product information and professional technical advice, and look forward to working with customers all over the world to establish mutually beneficial and win-win long-term cooperative relationships!