Won the title of “Excellent Supplier” of Sany, making Lutong drive axle the “power anchor” of construction equipment.

The annual supplier conference of the loader division of Sany Heavy Industry, a leading global construction equipment company, recently concluded.In the face of fierce competition from many suppliers of key components, Shandong Lutong Heavy Industry Machinery Co., Ltd.distinguished itself with its outstanding technical strength, stable product quality and efficient delivery service in the field of drive axles and was awarded the honorary title of “Excellent Supplier” of the year.This recognition from leading industry experts carries much more weight than just a certificate of appreciation.This is not only a confirmation of Shandong Road's efforts as Sany's core strategic partner in the past few years, but also a kind of prism reflecting the clear trajectory of China's major component manufacturing companies in the process of reconstructing the value chain of the construction machinery industry from "support" to "value-added."The cornerstone of all this is the continuous updating of the complete range of products for forklift drive axles and the wide range of customised solutions.

1. Honor Stands From Stable Support to Strategic Coordination, Upgrade and Maintenance Value The title of “Excellent Supplier” is a very high recognition rate in Sany's strict supply chain evaluation system. Its selection criteria are not limited to on-time delivery and product batch speed, but also include comprehensive aspects related to technological innovation, quality life cycle management, value for money, and supply chain resilience to market fluctuations. Shandong Lutong has been able to achieve this award, indicating that the cooperation between the two parties has moved beyond the traditional “purchase-supply” relationship and has entered the stage of in-depth strategic cooperation, characterized by joint technology research, expansion of markets and shared values.

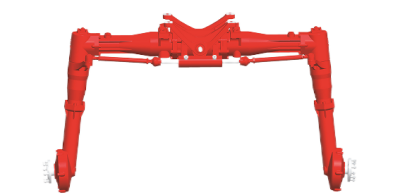

The establishment of this relationship is made possible by Shandong Lutong's accurate understanding of the major needs of equipment manufacturers and timely response to them. Sany's range of forklifts ranges from small and medium models that are suitable for urban and agricultural land conversion, to large and extra-large models that are suitable for mines and ports. Working conditions vary widely. The loader drive axle supplied by Shandong Lutong is by no means a standard “one move fresh” product, but is a highly flexible product matrix. Its main advantages primarily come from excellent compatibility with platforms and a variety of speed ratios. Shandong Lutong drive axle products can have different key connection sizes and installation interfaces, which can be easily adapted to multi-tonnage loader platforms of different generations of Sany. More importantly, the company can offer various RPM configuration options so that OEMs can precisely optimize the power chain according to the typical duty cycle and engine characteristics of the target market, to help the entire machine achieve higher operating efficiency and fuel economy at the source.

Secondly, it is a design philosophy based on reliability. The operating environment of the loader is harsh, and the drive axle can withstand shock and torsion loads for a long time. Oil leakage and abnormal wear are common problems in the industry. Through continuous design optimization and the introduction of innovative materials in the seal system, Shandong Lutong has ensured that the oil leakage rate of the drive axle has been significantly reduced compared to the industry average. This meticulous attention to detail directly translates into higher levels of service for terminal equipment and lower after-sales costs, which is a key factor for manufacturers such as Sany to build product reputation and appeal to customers. customers in a global market competition.

2. The cornerstone of intelligent manufacturing: robotic production line and digital control, stable casting quality. Acquiring honor is inseparable from solid and reliable production capabilities as the foundation. The modern Shandong Lutong factory, built to produce core components of the loader drive axle, has an intelligent production line efficiently running. Here, the processing of key components such as axle housing, main gear housing, planetary wheel frame and differential housing, no longer depends on the traditional old master model, but is carried out by automated units equipped with world-class robots such as ABB, FANUC, and KUKA. .

Controlled by precision CNC machines, these “steel arms” perform a series of complex processes such as milling, drilling and tapping. Their repeated positioning accuracy reaches the micron level, which completely eliminates quality fluctuations caused by human factors. Intelligent production lines not only improve production efficiency and cost control, but also ensure maximum consistency in product quality. For each part produced offline, the main dimensions, as well as shape and position tolerances are fixed within a narrow range specified by a digital program, which lays an impeccable foundation for subsequent high-precision assembly. The assembly unit is another "precision surgery". The dedicated forklift drive axle assembly line utilizes special tooling fixtures to ensure that assembly components are always in the theoretically designed position during the assembly process. A highly standardized assembly process minimizes human assembly errors and ensures that every drive axle supplied has the same qualities - longer service life, low noise and vibration in operation and superior reliability in the factory. From raw material storage to By releasing finished products offline, quality data from the entire process is collected, monitored and analyzed in real time, creating a traceable digital quality file that provides the scientific basis for continuous process optimization and quality improvement.

3. Product Evolution: Electrification and high-end two-wheel drive in the future Facing the irreversible wave of electrification and intelligentization of construction machinery, Shandong Lutong is not satisfied with its advantages in the traditional industry, but, guided by a promising layout, has introduced a drive solution specifically designed for electric forklifts. The characteristics of the electric drive system such as high torque, fast response and energy recovery are carefully taken into account, as well as The design is comprehensively optimized.

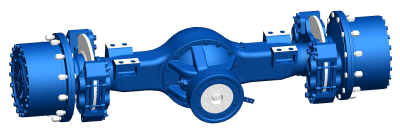

The electric forklift's drive axle is equipped with an efficient NGW planetary gearbox, which provides a wide ratio range and high load capacity in a compact environment. Its transmission system has been specifically designed to match engine performance to maximize transmission efficiency and thereby extend battery life. The braking system has also been upgraded for use in electrified environments, using high-torque disc brake calipers that respond quickly and provide energy recovery and synergy with engine braking to improve overall energy efficiency. This specially designed electric forklift drive axle is no longer an independent component, but an integral and optimized core module of the electric forklift power system, which truly helps OEMs unlock the performance potential of electrical equipment.

At the same time, in the high-end market, Shandong Lutong is actively promoting forklift drive axles equipped with wet braking systems. For equipment operating in harsh conditions, high speed and long descents, such as mines, tunnels and large-scale infrastructure, thermal decomposition and failure of the brake system pose a serious safety risk. Wet braking technology allows multiple friction brake pairs to be completely enclosed in a cavity filled with coolant. oil, resulting in much greater braking torque than traditional dry braking and extremely consistent performance. In continuous downhill conditions, superior heat dissipation results in virtually no thermal decay, ensuring consistent braking force. It is especially important that the fully enclosed oil bath design completely eliminates sparks during braking and provides an intrinsically safe solution for flammable and explosive environments such as underground coal mines and petrochemical industry. Additionally, due to the lubricating effect of oil, brake pads wear extremely slowly, significantly extending the maintenance cycle and reducing lifetime costs, making it the “preferred configuration” for high-end customers seeking safe, efficient operation with low maintenance costs.

4. Empowering the system: the role of the supply chain - from stable supply to environmental cooperation. The title of "excellent supplier" is also a testament to Shandong Lutong's high level of supply chain service. In today's unstable global market environment, stable supply volume itself is a scarce strategic resource. Relying on scientific production capacity planning and raw material reserves, Shandong Lutong has built up sufficient inventory of finished products and key components, allowing it to respond quickly to changes. manufacturers' production plans and rush orders, ensuring timely and accurate deliveries. This capability has significantly increased the supply chain resilience of OEMs like Sany to changes in market demand and ensured project longevity.

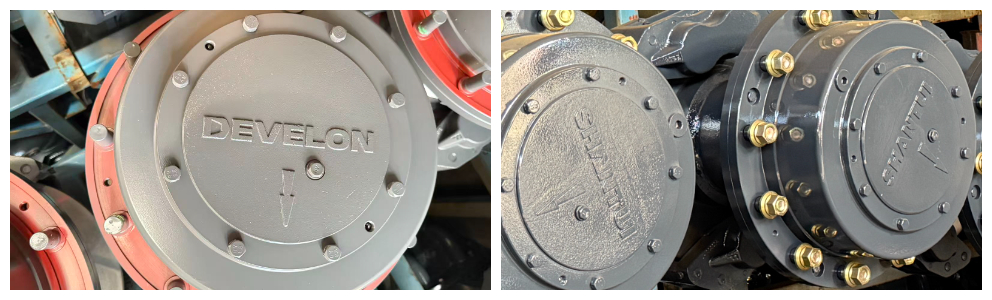

The higher level of service is reflected in pre-production preparation and technical support coordination. Shandong Lutong's engineering team was involved early in the new product development process for OEMs. Based on extensive application database and simulation analysis capabilities, they have provided proposals for drive axle selection and drive axle matching optimization to jointly solve power circuit layout problems. Extensive cooperation with companies such as Sany, Shantui, Lovol, famous domestic and foreign companies such as Taizhong Group, Borreton, Hyundai, Diwanlun, etc., has enabled Shandong Lutong to accumulate in-depth application knowledge of various brands and scenarios. This knowledge contributes to continuous product improvement and can provide new and innovative solutions. legacy customers receive more targeted solutions, creating a virtuous cycle of application-improvement-reuse.

5. Looking to the Future: Innovate core components to take Chinese manufacturing to the next level Winning SANY "Excellent Supplier" is an important milestone and a new starting point. This means that Shandong Lutong's status as a leading high-quality components manufacturer in China has been confirmed by the competent market authorities. Looking to the future, competition in the construction machinery industry will increasingly focus on the overall efficiency of the industrial chain, product life-cycle cost and the speed of implementation of environmentally friendly intelligent technologies.

Shandong Lutong will continue to adhere to the concept of “technology leadership, quality-oriented and customer-oriented” and will deepen its development in the following directions: First, continue to improve technology solutions for mature products such as forklift drive axles, and strive for weight limitation, noise reduction, and transmission efficiency. Second, fully embrace electrification, develop more integrated and intelligent electric drive systems, and create an open cooperation ecosystem with equipment manufacturers and companies. producing battery motors. Third, introduce advanced technologies such as wet braking into new product lines to improve the safety of a wider range of construction equipment. Fourth, strengthen the construction of digital factories and supply chain systems and become a trusted “energy partner” for customers around the world, providing them with more transparent, flexible and reliable supply services.

Standing at the historical threshold of China's construction machinery development from leading scale to advanced technology, Shandong Lutong is an excellent core component company introduced by Shandong Lutong. Thanks to its innovative capabilities and high level of production, it provides a constant supply of “core” energy for the modernization and breakthrough of the entire machine manufacturing industry. They work hand in hand with equipment manufacturers to create not only reliable equipment, but also a valuable business card made in China, which is becoming increasingly popular in the global market.