Turkish customers visited Shandong Lutong for research and negotiations to explore new cooperation opportunities in the field of drive axles.

Recently, Mr. Mustafa, a well-known corporate customer from Turkey in the field of construction machinery and national defense equipment, made a special visit to Shandong Lutong Drive axle Manufacturing Co., Ltd.(hereinafter referred to as “Shandong Lutong”) for a two-day study tour.negotiations on cooperation.This time, Mr. Mustafa's visit involved precise coordination and numerous rounds of online communication between the two sides via the Google platform.The customer seeks to verify on-site the production efficiency, product quality, and foreign trade service capabilities of Shandong Lutong, and to lay the foundation for subsequent wholesale purchases of drive axle products.During the investigation, the two sides had comprehensive and in-depth exchanges and discussions on key issues such as customized drive axle product development, serial delivery cycles, establishment of overseas after-sales service system, and joint expansion of regional market.The atmosphere of the negotiations was warm and harmonious, and finally, consensus was reached on a number of key terms of cooperation and a preliminary letter of intent for cooperation was signed, which laid a solid foundation for the beginning of long-term and stable cooperation between the two sides.

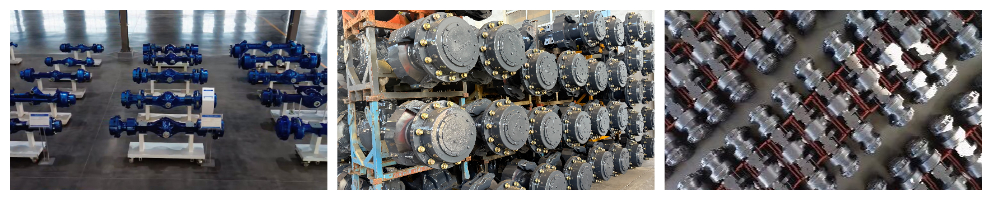

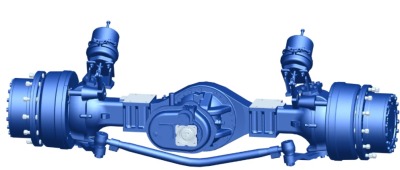

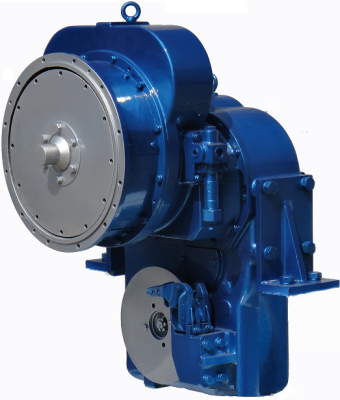

As one of the leading enterprises in the field of domestic drive axle production, Shandong Lutong has been actively engaged in the research, development and production of drive axles since its establishment. Today, the company has nearly 30 years of experience in the industry, focusing on R&D, production and sales of three main components. product series: construction machinery drive axles, mining machinery drive axles and agricultural machinery drive axles. The company is located in Feicheng High-tech Industrial Park, Shandong Province, covering an area of more than 100 acres, has 5 standardized production workshops and an annual production capacity of more than 50,000 units (sets) of drive axle products. It is one of the few drive axle manufacturing enterprises in China. with independent production facilities throughout the entire process. With excellent quality control, continuous innovation, R&D and a perfect global after-sales service network, the company's products are not only distributed to more than 30 provinces, cities and autonomous regions in China, but also exported to Russia, Belarus, Iran and other countries and regions around the world. has gained a good brand reputation and a stable customer base in the international drive axle market. This time, Mr. Mustafa came here to experience the company's production capabilities, R&D innovation level and core product competitiveness. He visited the main parts processing workshop, finished product assembly workshop, R&D center and product showroom to understand the company's comprehensive strength in all areas.

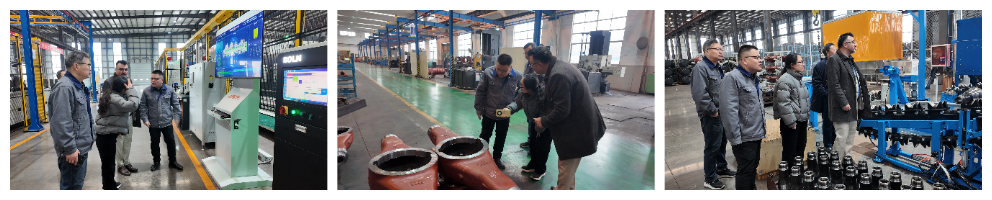

In the company's core parts processing workshop, Mr. Mustafa, accompanied by the company's on-site production director, inspected the entire manufacturing process of drive axle core parts, from high-quality alloy steel cutting, precision forging, to CNC machining and heat treatment, surface treatment and other key processes, each production link was carefully monitored and studied in detail. The workshop has dozens of internationally advanced CNC machining centers, intelligent Welding robots, high-precision grinding machines and other production equipment operate at high speed, providing automation, intelligence and high-precision processing of core components, effectively ensuring product consistency and stability. The company's production director introduced Mr. Mustafa: “Shandong Lutong has always put product quality first and has implemented a complete quality control system from the procurement of raw materials to the delivery of finished products. All raw materials are sourced from well-known domestic steel companies and undergoes strict testing. The machining accuracy of key parts is controlled within 0.005mm, and key processes are equipped with online testing equipment to ensure that each part meets design standards." Subsequently, Mr. Mustafa visited the finished product assembly workshop and observed the assembly process of the construction machinery drive axle and the mining machinery drive axle on site. The technical staff explained in detail the product assembly process, the main technical points and the operational advantages. When it is understood, Shandong Lutong can offer customers customized drive axle solutions according to the special needs of different application scenarios, especially for the mining machine drive axles independently developed by the company, which adopts high-strength housing structure, advanced gear design and efficient heat dissipation system, which can adapt to different operating conditions. harsh working conditions associated with high underground loads, high dust levels and strong shocks. When the service life was more than 30% higher than the industry average, Mr. Mustafa stopped to observe, personally inspected the product parts and praised the fine workmanship and stable performance of the product: “We were deeply concerned I have been working in the Turkish mining equipment market for many years. Over the past few years, I have deeply realized the importance of the reliability of mining equipment drive axles for the operation of equipment. Shandong Lutong mining equipment drive axles fully meet the needs of our market in terms of design and performance and even exceed our expectations.” In addition, Mr. Mustafa also visited the company's quality control center and learned more about the testing of fatigue life, sealing, load capacity and many other testing processes of drive axle products, and fully appreciated the company's strict quality control system. Quality control system.

At the subsequent special negotiation meeting, Shandong Lutong Foreign Trade Department Manager led the team to fully demonstrate to the delegation the company's foreign trade service capabilities and performance in the global market. The Foreign Trade Department Manager introduced: “To accurately meet the needs of customers around the world, the company has formed a professional foreign trade service team. The team members have many years of experience in foreign trade, speak English and many other foreign languages, and can provide a full range of services to overseas customers. Provide bilingual services. In addition, the foreign trade department also introduced the delegation in detail to the company's overseas logistics and distribution system and after-sales service network: the company has established long-term cooperation with a number of world-renowned logistics companies, and can choose various modes of transportation such as sea and air transportation, according to customer requirements, we ensure fast and safe delivery of products, at the same time, after-sales service points have been established in key markets; equipped with professional maintenance technicians and sufficient spare parts, which can provide customers with fast and prompt after-sales service and effectively solve customer problems. During the negotiation process, both parties held in-depth discussions on the specific details of cooperation, the Turkish delegation put forward the customized requirements for the drive axles of construction equipment and mining equipment for the Turkish market, including the adaptation of product models, operating parameters, external design and serial delivery cycles, the team and the foreign trade department carried out professional consultations on site and promised to complete. preliminary development of an individual plan within one week and submit it to the delegation for consideration.

The CEO of Shandong Lutong expressed his gratitude to Mr. Mustafa for his recognition. He said: “Shandong Lutong has always adhered to the development concept of “Quality first, customer first and global development.” Over the years, the company has continuously invested in research and development to continuously improve product competitiveness and production level. The quality of the drive axle, which is the core component of construction machinery, mining machinery and other equipment, is directly related to the operating efficiency and service life of the equipment. The company has always controlled every production link in accordance with high standards and strict requirements and is committed to providing customers worldwide with the best drive axle products and solutions of the highest quality. These negotiations with Mr. Mustafa are an important opportunity for the company to expand the market in Central and Eastern Europe. As an important market in Central and Eastern Europe, Turkey has an advantageous geographical location and great market potential. Cooperation with Turkish customers will further improve the company's position in the global market. In the future, the company will continue to increase investments in overseas markets and continuously optimize the foreign trade service system. will speed up the research and development process of new products such as new energy drive axles and intelligent drive axles to meet the global market demand for environmentally friendly and intelligent equipment on the other hand, it will further improve the overseas after-sales service network, improve the response speed of service teams, and provide more efficient and professional services to customers around the world. We firmly believe that with the joint efforts of the two sides, we can achieve complementary advantages, mutual benefit and win-win situation, and jointly explore a wider market space.” At the same time, the CEO also accepted Mr. Mustafa's invitation and said that he will organize a team trip to Turkey in the near future to gain a better understanding of the local market situation and customer needs, and promote cooperation between the two parties for speedy landing.

This visit of Turkish customers to the enterprise not only demonstrated Shandong Lutong's strengths and good international reputation in the field of drive axle manufacturing, but also laid an important foundation for further expanding overseas markets and deepening international cooperation. Shandong Lutong sincerely welcomes equipment manufacturers, distributors and partners from major companies in construction machinery, agricultural machinery, mining machinery and other industries around the world to visit the company and discuss cooperation. Adhering to an open and inclusive approach, the company will operate hand in hand with customers around the world, relying on our own R&D, manufacturing advantages and perfect foreign trade service system to provide partners with customized drive axle solutions, stable product supply and high-quality after-sales service. We believe that in the context of global cooperation, through in-depth cooperation and joint efforts of the two parties, we can jointly confront market risks, seize industry development opportunities, and work together to expand the global market and create new splendor in the drive axle industry! In the future of Shandong Lutong will continue to expand the field of drive axle production, continue to innovate and forge ahead, aiming to become the world's leading drive axle solution provider and contribute to the high-quality development of the world's construction machinery, mining machinery and other industries. The power of China.