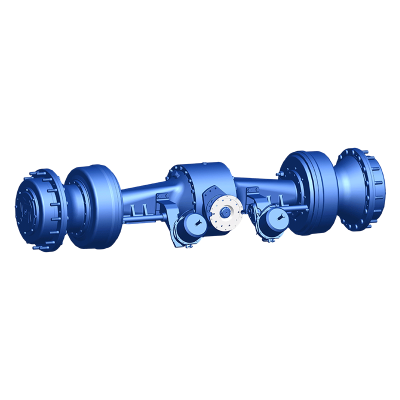

Transmission and torque converter assembly

1.It is possible to avoid engine shutdown due to external load fluctuations.Meets the requirements of construction work conditions.

2.High-precision manufacturing, dimensional consistency, assembly accuracy, reliability in warranty.

3.Various characteristics of speed and torque of the combined model, it meets different requirements.

4. requirements for loader configuration

5.Disc brake caliper or drum type brake.

6. Suitable for forklifts with a volume of 1.5-2.0 cubic meters. m.

Introduction:

The gearbox and torque converter assembly is designed for forklifts with a bucket capacity of 1.5 to 2 cubic meters.Designed with high precision manufacturing, it offers many combinations of gear ratios and torque conversion characteristics.The system includes customizable parking mechanisms to meet various requirements for the main vehicle, ensuring compatibility with different working configurations.

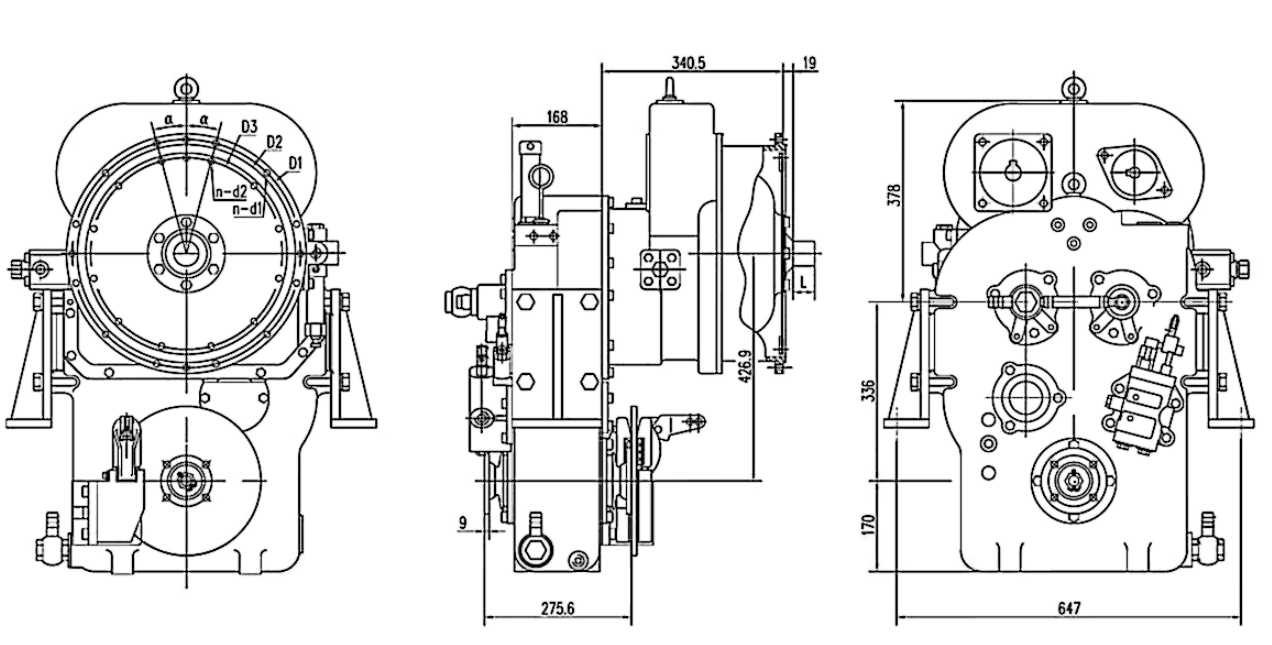

Main Technical Parameters:

Model transmission |

Transmission ratio |

Hydraulic torque converter model |

Day 1 |

D2. |

$D3 |

n-d1 |

n-d2. |

L. |

α |

Weight |

Operating temperature |

Request for oil |

|

ZL15. |

ANDF1=2.47 |

ANDFⅡ=0.88 |

YJ280. |

Ø428.6. |

Ø409.6h7. |

Ø360. |

12–Ø11 |

12–Ø11 |

40 |

15° |

325Kg. |

80-110℃ |

|

ANDRⅠ=2,52 |

ANDRⅡ=0.90 |

Ø340. |

3-Ø13. |

||||||||||

ZL15-1. |

ANDF1=2.16 |

ANDFⅡ=0.77 |

280-1 |

Ø440. |

Ø416h7. |

Ø290. |

9-Ø13. |

12–Ø11 |

30 |

40° |

|||

ANDRⅠ=2.21 |

ANDRⅡ=0.79 |

||||||||||||

ZL15-2. |

ANDF1=3.10 |

ANDFⅡ$D3 |

n-d1 |

Ø428.6. |

Ø409.6h7. |

n-d2. |

12–Ø11 |

12–Ø11 |

40 |

15° |

|||

ANDRⅠL. |

ANDRⅡα |

||||||||||||