The strength of the Shandong Lutong drive axle reflects the solid foundation of “Made in China”

The International Convention and Exhibition Center in Bangalore, India was bustling with people as the five-day International Construction Equipment Exhibition EXCON INDIA 2025 in Bangalore, India concluded on December 13, 2025. As the benchmark exhibition for construction equipment in South Asia, the exhibition brings together the world's leading equipment manufacturers, parts suppliers and industry experts, as well as Shandong Lutong Drive axle Manufacturing Co., Ltd. (hereinafter referred to as “Shandong Lutong”) from China, which offers high quality products. drive axle products designed specifically for construction, agricultural and mining equipment became one of the most popular Chinese exhibitors at the exhibition.

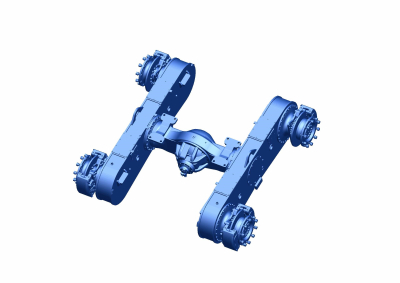

"Infrastructure construction in India and nearby South Asian countries is experiencing a booming period, and the process of agricultural modernization is also accelerating. The demand for drive axles with high load capacity and durability is extremely high. Shandong Lutong presented it on site: "The construction machinery drive axle we brought this time can be adapted to excavators, loaders, graders and other machinery." Many local machine tool manufacturers in India came to negotiate with tables of parameters of their own equipment, and some companies even offered to build a localized drive axle adaptation center together with Shandong Lutong, which indicates the market attractiveness of their products.

The competitiveness of the products is due to the high production capacity of the enterprise. Shandong Lutong is located in Feicheng Machinery Manufacturing Industrial Park, Tai'an City, Shandong Province, covering an area of 150,000 square meters. m, of which the production workshop occupies an area of 100,000 sq. It is one of the leading professional production bases for drive axle production. The company has a series of intelligent drive axle production lines, the main processing equipment of which is imported from Germany and Japan, including multi-axis machining centers, CNC horizontal lathes, automatic welding lines, etc. “Taking differential housing, the main component of construction machinery drive axle, as an example, we use the automatic differential line processing center for one-time molding, and the dimensional accuracy can be controlled within 0.005mm, which is equivalent to 1/10 of the diameter of a hair, which basically guarantees the stability of the drive axle transmission.” The annual production capacity of the company's numerous production lines can reach 50,000 sets, which can fully meet the supply needs of large-scale orders.

In terms of intelligent manufacturing, Shandong Lutong is at the forefront of the industry. The company has implemented a production management system to digitally manage the entire production process of drive axles. From the moment raw materials are stored, each component is assigned a unique “identification code”, which can track its processing progress, equipment information, operators and other data in real time. “Our intelligent production line can operate continuously 24 hours a day, and the productivity of one production line per capita is more than 2 times higher than traditional production lines."Digital control makes the production process more transparent and controllable, and provides customers with accurate order progress information. This is also one of the important reasons for customer recognition at this exhibition.

If manufacturing strength is the “backbone” of a product, then the quality control system is the “lifeline” of the product. Shandong Lutong has always integrated quality control into all aspects of production, implemented a “triple quality control system” covering raw material inspection, process control and finished product inspection, and established an independent quality control center equipped with more than 30 professional inspectors and more than 10 sets of testing equipment. “For every batch of steel, gears wheels and other raw materials entering the workshop, we must analyze the chemical composition and test the mechanical properties. Unqualified raw materials are always returned. This is the first line of defense for quality control.” In process inspection, a special specialist is responsible for inspection after the completion of each process, and a “double inspection” mechanism is also established for key processes; The inspection of finished products is even more strict. All drive axles must undergo 12 stages of testing, such as load testing, idle speed, noise and sealing tests before leaving the factory. Construction equipment drive axles must also undergo fatigue testing to simulate use under extreme working conditions and ensure that products meet ISO9001 quality management system standards.

In recent years, with the active promotion of the Belt and Road Initiative, Shandong Lutong has been actively expanding overseas markets. Its products have been exported to many countries and regions in Russia, Belarus and Iran, and its share in overseas markets has been increasing every year. This appearance at the Indian Construction Equipment Exhibition has not only increased the popularity and influence of the brand in the South Asian market, but also given new impetus to the development of the company's overseas business. The end is not the end, but a new beginning. Shandong Lutong will always adhere to the concept of "survival through quality and development through innovation", constantly improve the production and quality of drive axle products, and occupy a worthy position place in the "Made in China" list in the global drive axle market, offering better products, more efficient services and better warranties, and contribute to the development of construction machinery, agricultural machinery and mining industries. The power of China.