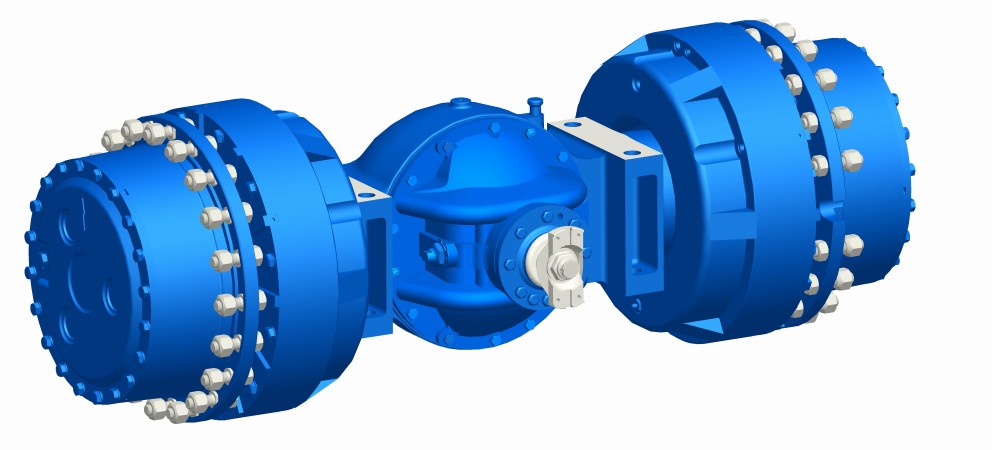

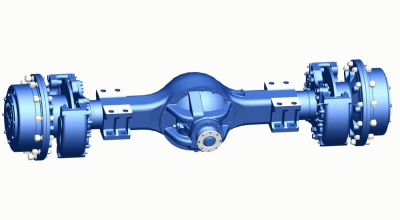

Drive axle of the CY20 borehole loader

1.The product has excellent stability.

2. Mature products, reliable quality.

3.It has been exported to many regions and has been fully tested by the market.

4.Excellent compatibility, can be adapted to 2 cubic meter soil scraper.

Product overview

Our CY20 downhole scraper drive axle is a high-performance drive solution designed for downhole operating conditions. The product was officially successfully developed in 2016. It combines advanced international technology with over 30 years of local manufacturing experience to achieve full compatibility with world-class brands. The drive axle of this downhole scraper strictly complies with international common interface standards at the design stage. Its installation size, bolt hole arrangement and transmission parameters are fully compatible with major similar model products in the world, and are suitable for 2 cubic meter underground loaders, which provides an efficient and reliable power transmission guarantee for underground mining.

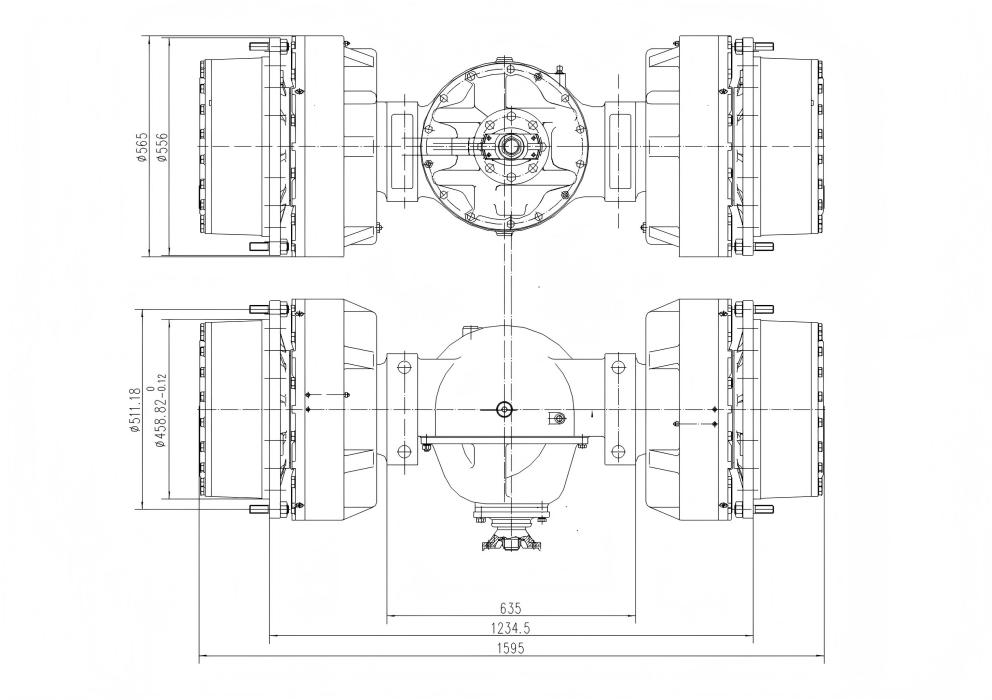

Main technical parameters:

Overall overall gear ratio |

26.118 |

Maximum input torque |

2668N.m |

Maximum load on the bridge |

18160 kg |

Brake structures |

POSI-STOP spring brake / hydraulic release, multi-disc, wet / forced cooling |

Oil pressure with the parking brake applied |

10.4 MPa |

Working volume of one-way brake |

163.9 ml |

Braking moment of one side |

20000N.m |

Oil for cooling brakes and relieving braking force |

Hydraulic oil L-HL46 |

Drive axle oil requirements (API classification) |

GL-5: transmission oil 85W/90 (use at temperatures above -12°C) GL-5: 80W/90 transmission oil (use at temperatures above -26°C) |

Product Features

1. The drive axle of this CY20 downhole loader complies with the international interface standard at the design stage, and its installation size, bolt hole position and transmission parameters are exactly the same as DANA products of the same model. This design allows equipment manufacturers to quickly replace the drive axle without changing the chassis structure, which greatly shortens the equipment renewal cycle and provides reliable support for the continuous production of mines.

2. The drive axle is equipped with a high-performance wet braking system, which functions as both driving braking and parking brake. The integrated design makes full use of the internal space of the drive axle, has a compact structure, and provides greater flexibility to the overall layout of the main engine. The wet brake is completely immersed in oil to operate, which effectively prevents the occurrence of open flames due to friction when braking, and greatly improves the safety of underground working, especially suitable for heavy-duty, high-grade working conditions. gas or dense dust. In addition, the braking system is equipped with a normally closed parking brake, which can be automatically locked when the engine is turned off or stopped, effectively preventing the vehicle from slipping, reducing the risk of human misoperation, and ensuring the safety of personnel and equipment.

3. Equipped with an anti-slip differential that ensures the vehicle's normal turning speed, the torque distribution between the left and right wheels can be automatically optimized according to the road traction conditions. This design can effectively suppress the slippage of one-way wheels, ensure excellent traction and driving stability of the scraper on slippery, muddy or bumpy dirt roads, and ensure efficient operation and safe handling in difficult road conditions.

4. We insist on using key components from world-famous brands, such as high-strength SKF bearings, high-strength friction linings and NOK oil seals. All components have undergone rigorous testing to meet customer requirements to ensure the consistency, stability and reliability of the overall drive axle.

5. Our technical team goes to the production sites of large mines to collect data on the operation of the drive axle under real operating conditions. By continuously optimizing key parameters such as bearing clearance, gear mesh parameters and lubricating oil flow path, overall drive axle performance and service life are improved. maximized. Longer service life means lower replacement frequency and maintenance costs. Through optimized design and precision manufacturing, our drive axles help users extend equipment cycle times and reduce downtime, thereby increasing the economic value of all equipment over its life cycle.

Product Application

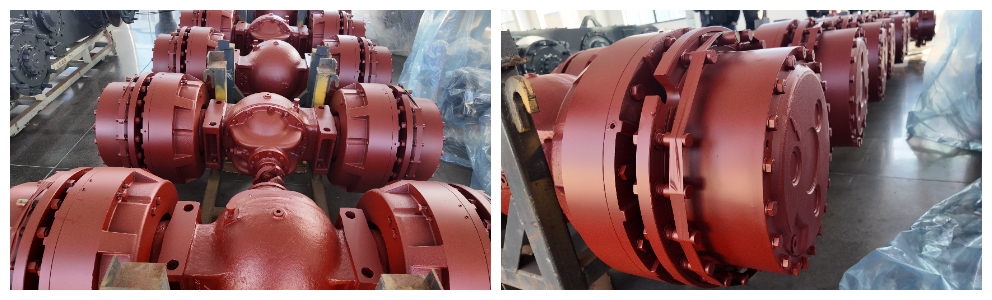

As one of the first manufacturers in China to mass produce downhole loader drive axles, we have more than 30 years of professional manufacturing experience. From early introduction and mastery of foreign technology to independent innovation, research and development, we have accumulated deep technical experience and mature technology system. Our CY20 downhole loader drive axle has been shipped in batches to Qingdao Zhonghong for a long time, Yantai Dali, Shandong Hongke, Taian Hyundai, and also exported to Russia. It has withstood the harsh tests of high temperature, high humidity, dust and continuous operation under harsh conditions. Positive feedback from users around the world fully proves the reliability and adaptability of the product. Our 2 cubic drive axles are manufactured by a special intelligent machine equipped with special tooling and fixtures, which greatly reduces the moving and replacement time in the processing process. This not only improves production efficiency, but also ensures a high degree of consistency and quality stability between production batches, and also eliminates quality fluctuations in the production process. In addition, we have established a perfect quality feedback and technical improvement circulation system, and according to the actual use in different regions and mines, we continue to optimize the design details and drive axle manufacturing technology to ensure that each generation of products can better meet the actual needs of users.

Intelligent Manufacturing System

At present, the company has 13 sets of robots, 30 sets of Hyundai Weiya machining centers in South Korea and more than 50 sets of high-precision CNC equipment. In addition, intelligent production lines have been established, such as automatic welding lines, intelligent planetary wheel frame production lines, intelligent production lines for main gear housings, intelligent production lines for differential housings, and lever and bridge bodies.

Comprehensive quality control system

5S management standards are strictly adhered to in production, materials, work in progress, and finished products are clearly separated and labeled, and all equipment is subject to regular maintenance and preventative maintenance.

Checking incoming materials:All outsourced raw materials and components must be inspected, and unqualified products must be stored separately to prevent them from entering the production line.

Quality control of the technological process:The flow of materials strictly follows the principle of “first in, first out”, and each technological process is carried out in accordance with technological documentation. Advanced testing equipment: equipped with metallographic microscopes, microhardness testers, ultrasonic flaw detectors, three-dimensional coordinate measuring instruments and other precision testing instruments. Comprehensive testing of material structure, heat treatment effect, internal defects and processing accuracy.

Checking the functionality of the entire bridge:Each drive axle must undergo a series of performance tests, such as noise levels, temperature rise, sealing and transmission efficiency, on a special test bench.

Professional technical support

The company has a professional foreign trade team, which can communicate with customers to help them select the model accurately. Under special operating conditions, the foreign trade department can coordinate the technical team to conduct online or offline meetings with customers, obtain a detailed understanding of operating conditions, load characteristics and performance requirements, and provide recommendations on drive axle configuration and even customized design to ensure the product meets customer requirements. fully adapted to real operating conditions.