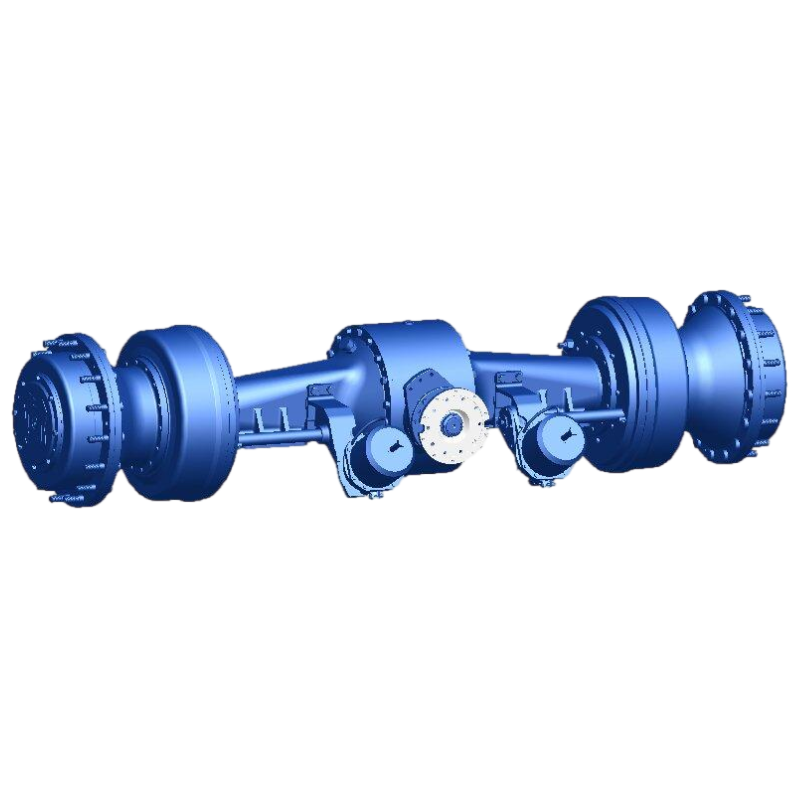

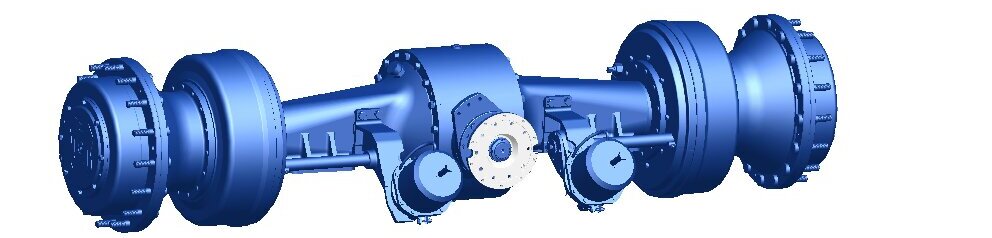

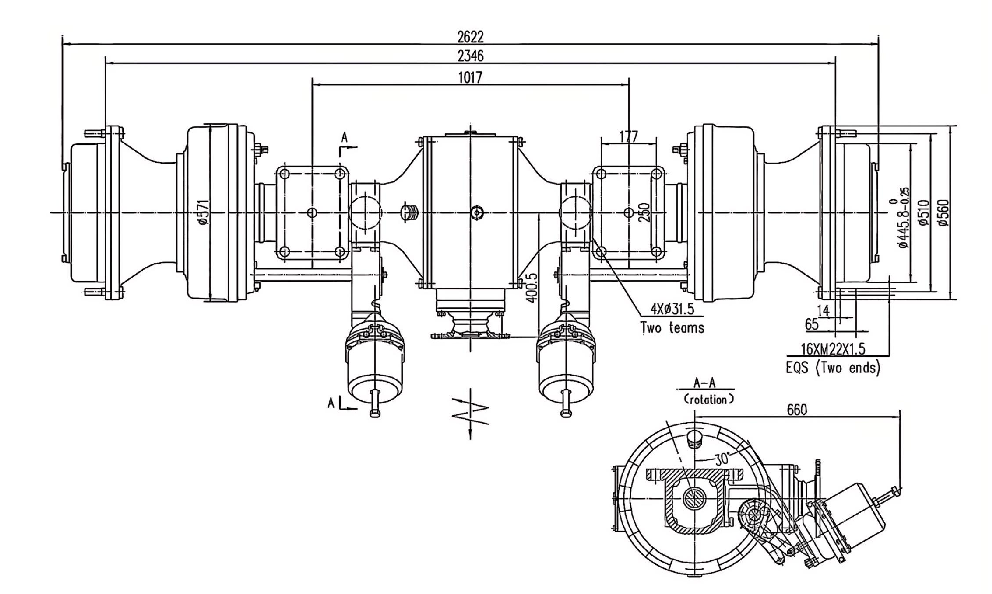

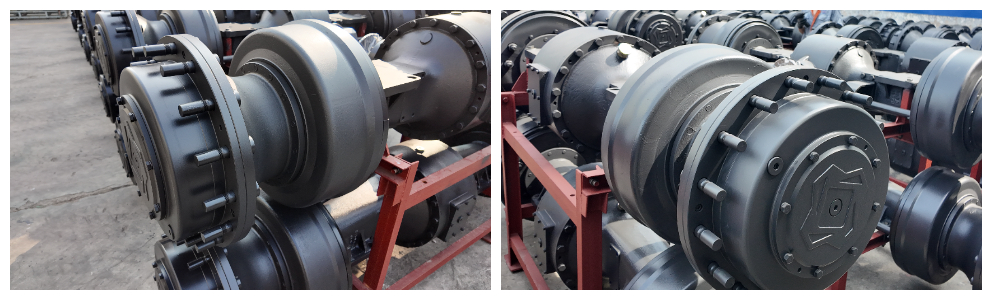

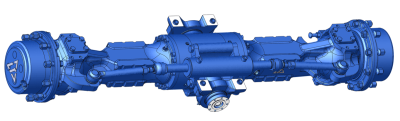

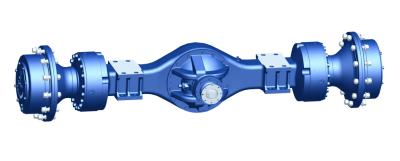

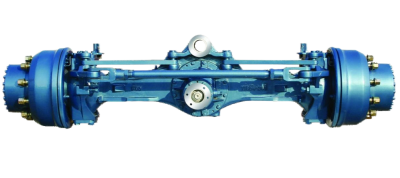

Drive axle of the T400 tractor

1. Two-speed gearbox with deceleration

2. Bridge body made of cast steel

3. Non-rotating, 100% non-slip limited slip differential

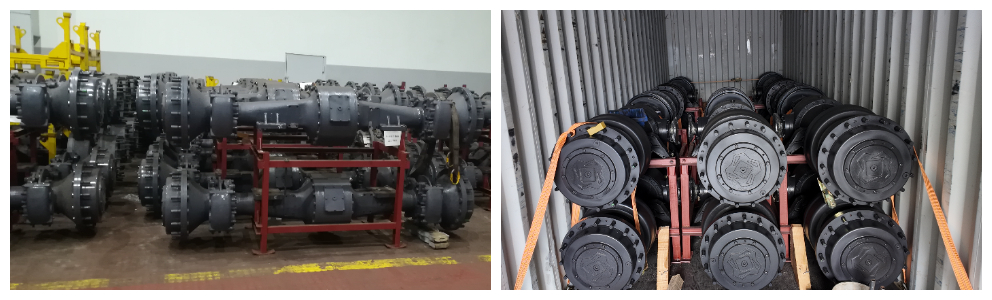

4. Exported to Russia in large quantities

5.Customizable

The T400 tractor drive axle is specially designed for the Russian market and is suitable for 400 horsepower tractors. The drive axle is the basis of stable operation - frequent overloads, low transmission efficiency, poor traction on difficult agricultural land and unstable braking when working in difficult conditions are the main problems that affect the work efficiency and increase maintenance costs. Our T400 tractor drive axle is specially designed to solve these problems, has a professional design and reliable performance to fully meet your power tractor operating needs. The product has stable quality, has been exported for many years with virtually no quality problems, and has been tested by the market.

Product Features:

1.Transmitting device for two-stage braking:

The T400 tractor's drive axle adopts a two-stage deceleration transmission, which effectively solves the problems of insufficient torque and easy wear of the drive axle caused by high-power operation, greatly extends the service life of the product, and reduces the frequency and cost of maintenance.

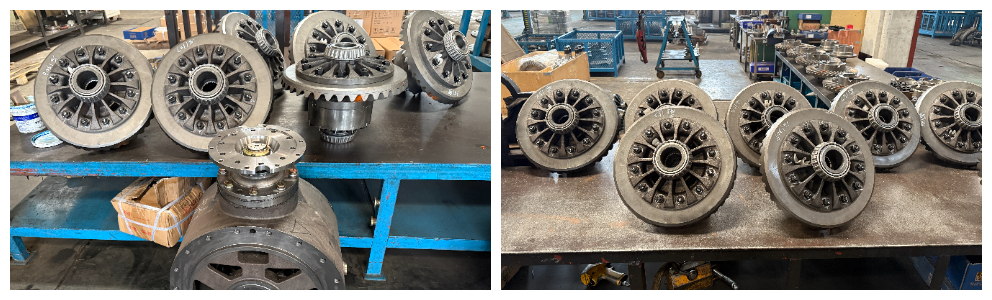

The main deceleration uses Gleason spiral bevel gear transmission system, and the wheel side secondary deceleration uses NGW planetary gear mechanism, which has high transmission efficiency, low noise and high load capacity.

MAIN TECHNICAL PARAMETERS

Overall overall gear ratio |

17.66 |

Maximum input torque |

9500N.m |

Load per bridge |

28,000 kg |

Brake system oil pressure |

11 MPa |

Braking torque of one caliper |

13000N.m |

2.Self-locking differential:

The integrated power transmission system is equipped with a limited-slip differential with a locking mechanism, which perfectly solves the problem of poor traction caused by wheel slip in difficult road conditions, improves traction control efficiency, avoids power loss, and ensures stable and efficient operation of your tractor even in difficult operating conditions.

3.Cast steel bridge body:

The bridge body is made of cast steel, cast as a single piece, with good rigidity and high load-bearing capacity.

4.Drum brake:

The braking system is equipped with drum brakes, which provide reliable braking force, quick response, and stable braking performance. Even after intensive and prolonged continuous operation, braking failures are avoided, ensuring safe braking and effectively protecting operators, tractors, and agricultural equipment.

Our T400 tractor drive axle combines professional technology and practical features, focusing on solving customers' major concerns in terms of efficiency, durability, safety and cost. It is a reliable choice for you to improve farming efficiency and reduce operating costs. We support customization according to your tractor model and regional operating needs, and provide professional after-sales service to solve your problems during operation.

Customer Approval:

Basic information about the main manufacturers: St. Petersburg Tractor Plant

St. Petersburg Tractor Plant LLC is one of the oldest machine-building enterprises in Russia and the founder of the domestic tractor manufacturing industry. The company produced its first tractors in 1924

PTZ was and remains the only domestic manufacturer in Japan that produces powerful wheeled agricultural tractors with high energy consumption. The production volume of Kirovitz tractors has exceeded 480,000 units.

Cooperation details:

Relying on high-quality drive axle products, professional customization capabilities and perfect after-sales service guarantee, our company has successfully passed several rounds of strict inspections (including product performance testing, quality system certification, production capacity audit, etc.) of the largest manufacturer, and has become the main supplier of drive axle accessories for its 400 HP tractors. and higher. The cooperation has been going on for 17 years.

1.Our tractor's T400 drive axle (suitable for 400 horsepower tractor models from leading manufacturers);

2. Cooperation scale: We have been supplying drive axles to the largest manufacturer for 17 years, and the annual supply is stably more than 5000 sets.

3. Cooperation mode: Under the long-term strategic cooperation, our company constantly optimizes the design and performance of the drive axle according to the upgrading needs of leading manufacturers, and provides customized technical support and after-sales service.

The leading manufacturer clearly stated:"The Shandong Lutong tractor's 400hp drive axle is ideally suited to the operating requirements of our high-power tractors. It features high transmission efficiency, a low failure rate, and excellent adaptability, effectively reducing the energy consumption of the entire machine. This fully meets our company's strict standards for auxiliary components."

Expanding the scope of application:

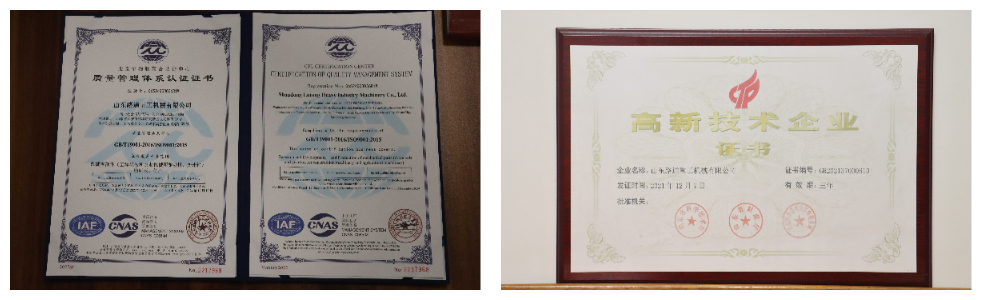

The opportunity to become the main support service provider for the leading manufacturer in the industry is sufficient proof that the product quality, performance and technical level of our drive axle have been recognized by authoritative industry bodies. Currently, our drive axle production standards and quality control system are synchronized with the requirements of the largest manufacturer to ensure the same high quality of each drive axle set, which can provide a stable and reliable support for your tractors and help you improve the competitiveness of your products.

Company strength:

Shandong Lutong has been specializing in the production of drive axles for machinery for 32 years, and annually produces 50,000 drive axles of various types and 20,000 torque converters for small gearboxes.

The company places great emphasis on quality management, safety, health, and environmental protection. It has implemented an ERP management system, received ISO9001 quality management system certification, and utilizes a Hexagon three-dimensional detector, an MDS metallographic microscope, and other testing equipment to ensure the precision and quality of product processing.

Technical Team:

The company has formed a professional and experienced technical research, development and technical support team to ensure continuous upgrading of drive axle products, stable quality and customized services. This is a key factor for us to develop the industry and win the recognition of customers around the world. The core team members have more than 15 years of experience in the field of construction machinery drive axles, including senior engineers, process experts, technical R&D specialists and other positions, and have deep technical knowledge and rich practical experience in core technical areas such as drive axle transmission structure design, gear drives. Precision machining, heavy-duty adaptation optimization, performance debugging and calibration.

We always adhere to the concept of development based on technological innovation. The technical team has long been focused on the needs of the overseas market and the technical challenges of the industry, and constantly promotes the iteration and upgrading of production technology. It can quickly respond to the individual technical needs of customers around the world and provide customized technical interfaces and programming. optimization and after-sales technical support. At the same time, the team has established close cooperative relationships with famous domestic universities and research institutes, and jointly conducted major technology research to ensure that the company's production technology will always be at the forefront of the industry, and provide customers around the world with more competitive drive axle products. and technical solutions.

Intelligent Manufacturing:

In the production process, the company attaches great importance to automation and intelligent upgrading. The core processes are fully realized with CNC intelligent manufacturing. Backed by high-quality automated production facilities, the company further ensures consistency, stability and efficiency in production, and ensures efficient and high-quality deliveries to customers around the world.

For the production of T400 tractor axles, we have specially equipped a specialized automated production line to automate the entire process starting from the processing of the main components, which greatly reduces errors caused by manual intervention, improves production accuracy and mass production efficiency, and allows us to quickly respond to the needs of customers around the world for bulk purchasing for 400 horsepower tractor axles.

The manipulators that are equipped in all production lines are equipped with advanced equipment from international brands, including ABB, KUKA, Fanuc and other world-famous automated equipment. They have the advantages of high precision, stability and efficiency. They can accurately carry out key processes such as gear machining, parts assembly and product processing, this not only ensures the machining precision and axle workmanship quality, but also effectively improves production capacity and helps us provide more competitive product delivery services to customers around the world.

Quality control:

To further ensure product reliability, all drive axle products must undergo strict full testing, including sealing test, noise reduction test, bench test and other key points, before leaving the factory, as well as comprehensive testing of product sealing, transmission stability, noise reduction and other key parameters to prevent the production of substandard products. from entering the market. For research and development of new products, we have created an additional authoritative verification mechanism. After completing the research and development of new products, they will be sent to reputable testing institutions such as China Automobile Research and Development to conduct professional simulation bench tests to comprehensively simulate the product performance under real operating conditions. After being carefully checked multiple times and confirmed that the quality is fully consistent with the requirements, it will be officially put into mass production and launched into the market, which will effectively protect the use experience and cooperation rights of customers around the world.

Sales and service:

Shandong Lutong is committed to providing customers with the most cost-effective products and the best quality services, and provides customized services. To quickly meet customer needs, we have a spare parts warehouse and an after-sales service team.

During the delivery process, we rely on stable production capacity reserves and an effective supply chain management system, which ensures rapid response and delivery within tight deadlines, and effectively resolves the major “late delivery” problems of customers around the world. For regular drive axle models, we create point reserves, and customers can respond within 24 hours after placing an order; For exclusive orders of T400 tractor axles, thanks to the efficient production capacity of the dedicated automated production line, production can be completed and completed quickly, allowing for faster order processing speed. more than the industry average.

We have established long-term and in-depth cooperation with a number of renowned logistics companies around the world to optimize international logistics and transport solutions, connect different customer regions, select the best transportation channels and significantly shorten the delivery cycle. Compared to similar products in the industry, our international delivery cycle is significantly shorter. this period is reduced by an average of 3-5 days, which allows customers to quickly receive products and put them into operation, effectively reducing customer costs for inventory and time, as well as improving the quality of cooperation.

As a leading supplier of drive axles, we have been dedicated to the research, development, and production of drive axles for many years. All products are ISO-certified and boast high efficiency, durability, and customizability. We provide customized solutions and localized after-sales service to customers worldwide.

Whether you're a tractor manufacturer, agricultural machinery distributor, or a large farm, we can provide you with high-quality drive axle products and professional services. Contact us now for a free quote or a customized solution – we'll contact you within 24 hours.