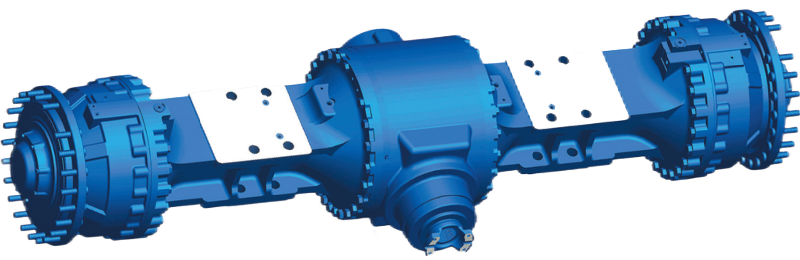

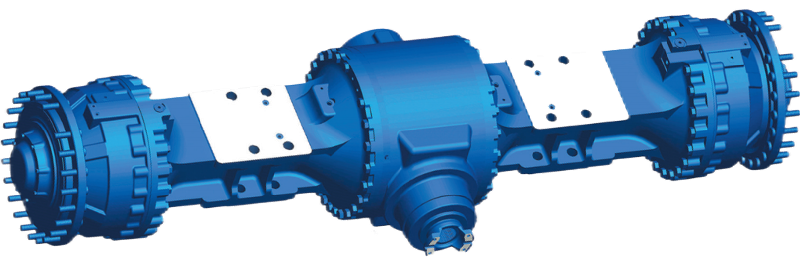

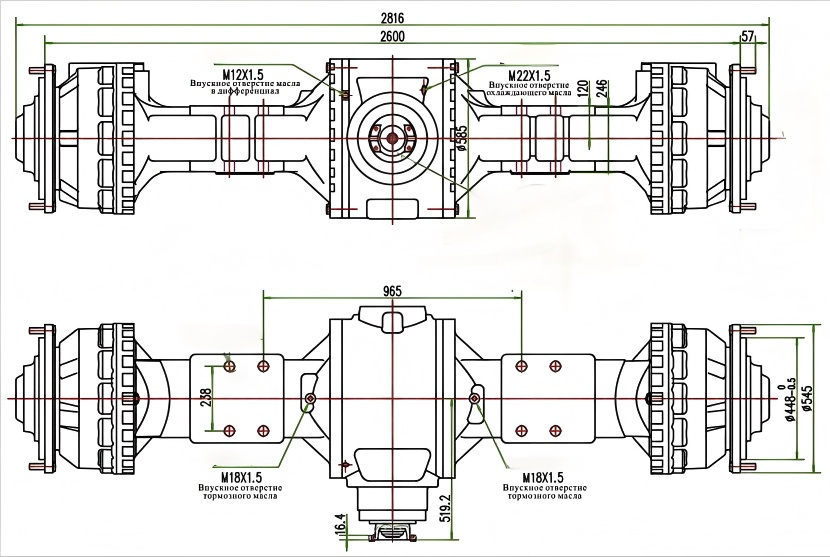

Front axle of a 10 ton loader

1.The bridge has a two-stage deceleration transmission structure.

2. Closed wet multi-disc brake, long-term and stable braking, safe and reliable.

3.Limited slip differential, hydraulic differential lock, high cross-country ability in difficult road conditions.

4.Floating oil seal on the wheel edge, good adaptability to dirty and dusty environment.

5.Forced cooling system, effectively improves the service life of the whole axle.

6.Suitable for 9~10 ton series forklifts.

Introduction:

The front axis of the 10-ton loader is the adoption of a two-stage delay structure, the exact distribution of power, a decrease in energy losses, so the loader in the operation of power transmission is more effective, it is easy to cope with difficult working conditions. Closed multi -disc wet brake, stable and reliable brake characteristics, with a differential of limited sliding and a hydraulic blocking of differential, can also protect the safety of work in dirty, slippery and other difficult road conditions of the construction site. Swimming seals on the edges of the wheels are protected from dirt, dust and sand. The circulation system of forced cooling in a timely manner removes heat in a timely manner, which effectively increases the service life of the leading bridge and reduces the cost of maintenance. Suitable for loaders of the series 9 ~ 10 tons.

Main Technical Parameters:

Overall overall gear ratio |

27 |

Maximum static load |

65000Kg |

Brake Oil Pressure |

10Mpa. |

Requirements for oil for the drive axle (API classification) |

GL -5: 85W/90 transmission oil (use at temperatures above -12 ° C) GL -5: 80W/90 transmission oil (use at temperatures above -26 ° C) |

Brake requirements |

Hydraulic oil L-HL46 |