What are portal bridges?

Technical History - What are portal axles? See how a specially designed drive axle solves the problem of extremely cold design

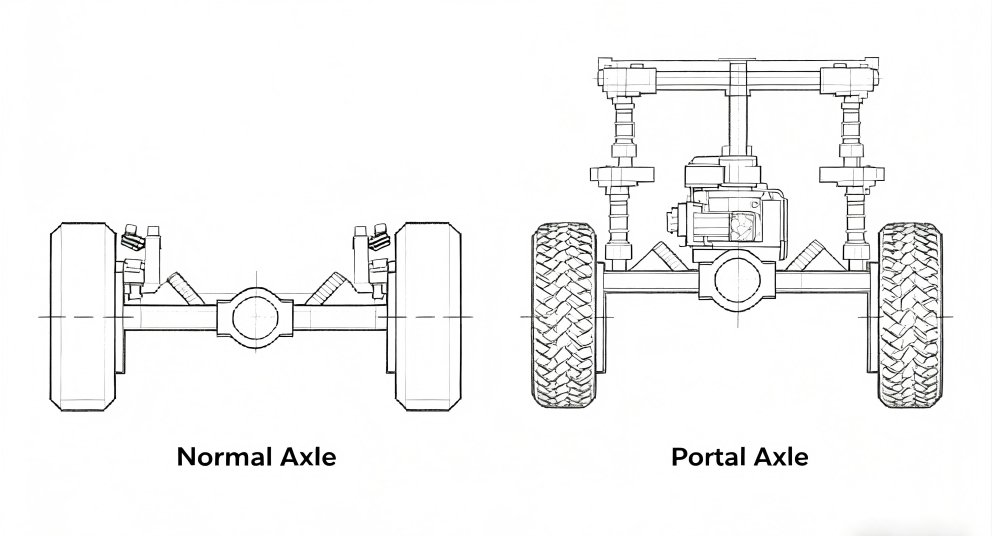

For off-road enthusiasts and special equipment engineers, portal axles are a symbol of cross-country capability and reliability. This is a special suspension and drive technology for SUVs, the key feature of which is the following: the center line of the axle shafts or axle housing does not coincide directly with the center of the wheel, but is located above it. Torque is transmitted to the wheels through an additional gear mechanism (the so-called “portal gears” or “wheel gears”) installed on each hub. You can imagine that a miniature “gear elevator” is built inside the wheel.

This system offers two revolutionary advantages:

Increased Ground Clearance: Because the final drive, differential and axle housing are raised by shifting the transmission line, the most vulnerable part of the chassis—especially the massive final drive housing—receives unprecedented clearance. This allows the vehicle to easily overcome rocks, stumps or deep holes that would be dangerous for conventional bridges.

Optimizing the load on the transmission:

Wheel gearboxes provide additional speed reduction and increased torque. This means that the final drive and axle shafts transmit less torque, allowing for lighter and more compact solutions (which also helps improve ground clearance). In addition, the load on driveshafts and transfer cases is reduced, increasing the reliability and service life of the entire transmission.

This technology is not new - its origins go back to the German WWII Volkswagen Type 82 military vehicle, which used portal gears with a 1.4:1 gear ratio to increase ground clearance and allow extremely low speed off-road driving. Today, portal bridges are used not only in top SUVs and agricultural machinery, but also in an “upside down” form in low-floor buses for the convenience of boarding passengers. In special equipment, this classic design takes on a new life, especially in vehicles where high cross-country ability is critical.

Advantages and challenges - the technical dialectics of portal bridges

Like any engineering technology, portal bridges, for all their advantages, require careful balancing and overcoming certain difficulties.

Unsurpassed cross-country ability:This is the main advantage of portal bridges, allowing equipment to work in conditions inaccessible to conventional machines.

Optimized transmission:Torque distribution improves the operating conditions of the entire transmission, reduces potential failures, and increases durability. For heavy-duty equipment, this means greater productivity and lower maintenance costs.

Precise control at low speeds:Correctly selected gear ratios allow for stable movement at extremely low speeds, which is critical for precision work in difficult areas.

However, there are also difficulties:

Increased unsprung weight:Heavier and more complex hub assemblies can reduce ride and handling at high speeds.

Heat dissipation issues:During long-term intensive operation, compact gearboxes can overheat, which requires a well-thought-out cooling system.

Cost and complexity:More complex design means higher production and maintenance costs.

Thus, portal axles are not a universal solution, but a specialized technology for equipment where maneuverability and reliability are paramount.

A solution for extreme conditions – grader drive axles designed for the Russian market

With a deep understanding of portal axles, we've developed all-wheel drive axles for operation in the harsh conditions of Russia, Belarus, and other countries—deep snow, swampy terrain, steep slopes, and challenging mountain roads.

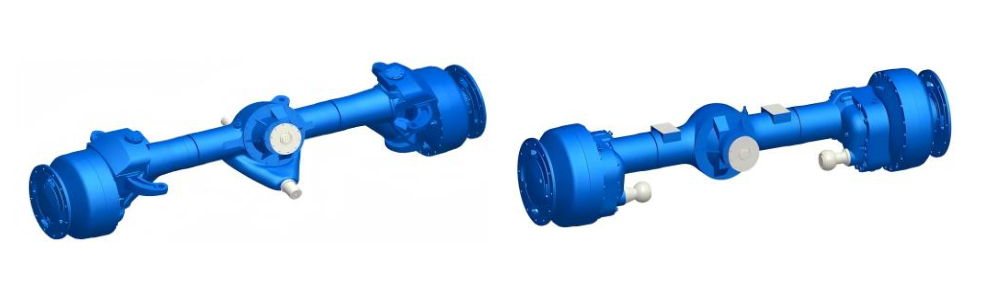

Three-axle drive for off-road and steep slopes:Unlike conventional graders, our system includes front, middle and rear axles to ensure optimal torque distribution and outstanding traction. This completely eliminates slipping and getting stuck, which is especially noticeable when working on slopes.

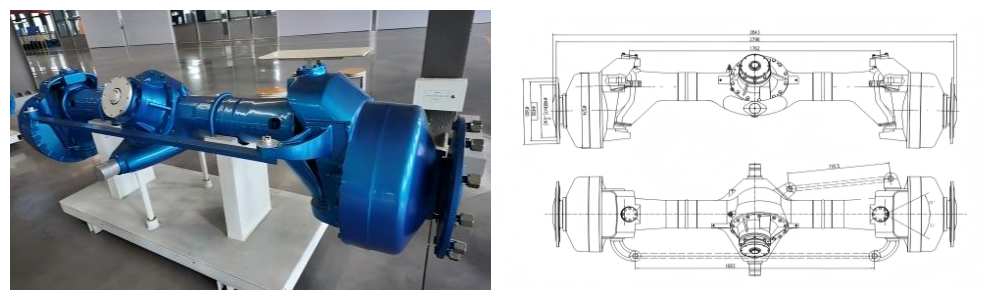

Front axle with portal design:This axle combines control and drive, providing high ground clearance and protecting key components from damage. Torque is transmitted via cardan shafts with crosspieces, and power steering ensures effortless control even when stationary.

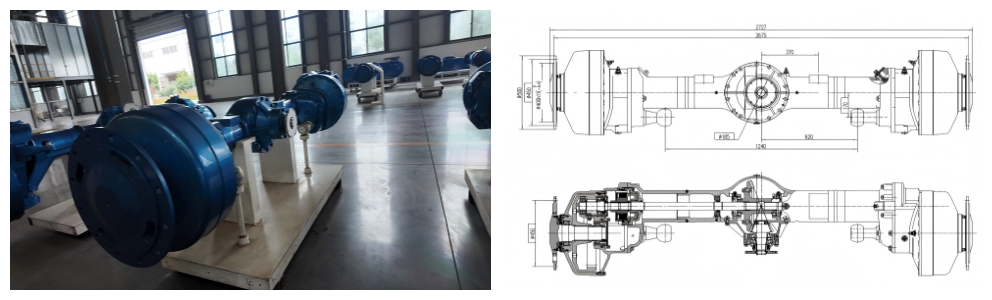

Unified middle and rear axles:These axles share a similar design, simplifying production and maintenance. The balance beam suspension provides improved traction on uneven surfaces, and the sophisticated design reduces repair time by 40%.

Customer Testimonials - Earning International Trust Through Superior Quality

True technical value must be forged in the fire of the market to emerge. Our company's specially developed grader axle has been put into mass production for high-performance motor graders in Russia and has undergone several harsh local tests under extremely cold winters and dirty spring conditions. This product, specially created for the Russian market, is the concentrated embodiment of deep our company's customization capabilities. The start of the project was driven by the specific needs of Russian customers: they needed a solution for driving a grader that could ensure efficient operation in the extremely cold climate of Siberia and difficult terrain.

At the early stage of the project, our company formed a dedicated technical team consisting of senior engineers and made three field trips to Russia. Our engineers personally visited several construction sites and had in-depth exchanges with equipment operators, maintenance engineers and project management personnel. During these field studies, we collected first-hand data on working conditions and needs users, including the impact of changes in lubricant viscosity on starting performance at extremely low temperatures, as well as the special traction requirements when driving in deep snow.

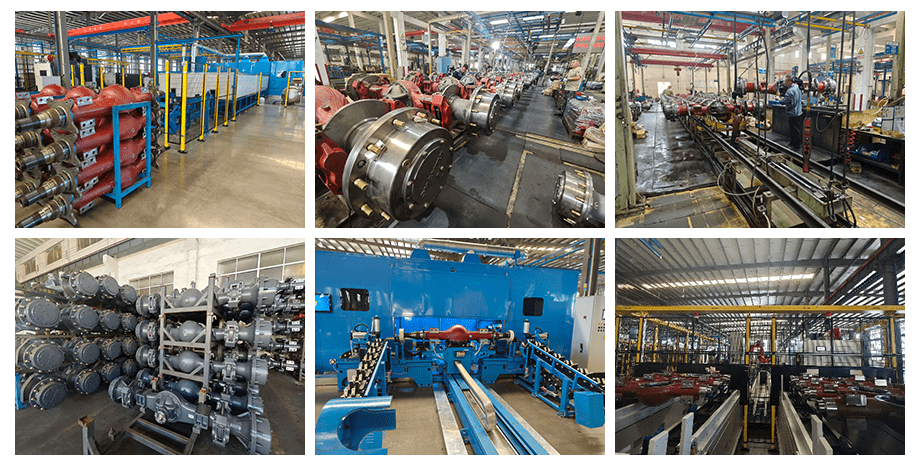

Based on this valuable data obtained on site, we maintain close communication and cooperation with the customer's technical team. This in-depth individual cooperation is reflected not only at the technical level, but also extends to the entire production process. We take full advantage of the company's flexible production and, while maintaining the standardization of core processes, have opened a dedicated production line for this project. From raw material procurement to processing and assembly, dedicated quality control points have been established at each link to ensure that every drive axle assembly leaving the factory meets the requirements of extreme operating conditions.

Customer reviews - quality you can trust

Our bridges have been tested in extreme conditions of Russian winters and spring thaws.

"Permafrost and spring mud used to be our main enemies. With graders equipped with your axles, everything has changed. The three-axle drive and high front axle clearance give us confidence even on the most challenging terrain. Reliability and durability have exceeded our expectations."

The strategy of deeply integrating engineering equipment needs is the right one. We not only offer a complete grader axle package, but also provide customers with a solution and the confidence to handle extreme operating conditions.

Future Prospects - Continuous innovation that will move the world forward With the increasingly stringent demands of the global infrastructure market for efficiency, flotation and reliability of equipment, the application prospects of portal axle technology in the field of special construction equipment will become increasingly broad. Looking to the future, our company will continue to improve portal axle technology and strive for:Light weight research: The use of new materials and new technological processes aimed at providing strength allows us to continuously optimize the weight of the rim system and improve control efficiency. We are exploring the use of high-strength aluminum alloys and composite materials in non-critical structural parts, which are expected to reduce weight by 15% of the weight of existing products while maintaining the same load-bearing capacity. Upgrade of the thermal management system: development a more efficient wheel lubrication and cooling system to meet the challenges of continuous operation under longer and higher loads. Next-generation thermal management system uses intelligent temperature control technology, monitors wheel-side system temperatures in real time using sensors and automatically adjusts cooling intensity to ensure the system always operates within the optimal temperature range. Intelligent Integration: Pre-configured drive axle condition monitoring sensors enable real-time monitoring of bearing temperature, transmission oil condition, etc., and advance preventative maintenance, which adds value to customers. In addition, we will further strengthen our customized service capabilities and create a perfect mechanism for quickly responding to customer needs. Thanks platform-based modular design concept, while maintaining product reliability, shortens the delivery cycle of custom-designed products. We will always focus on customer needs and use technological innovation as the engine to overcome more challenging construction environments for customers around the world and ensure a constant flow of core driving forces. Through continuous technological innovation and a perfect service system, we We strive to become the world leader in the production of drive axles for special construction equipment, so that "Made in China" shines even brighter in the global construction equipment arena.