The LHD drive axle: the heart of the LHD's power, ensuring efficient and safe operation

What is a Loading and Delivery Machine?

In the world of underground mining of ore, where the space is limited, the operating conditions are harsh, and the work continues continuously, extremely high requirements are imposed on the equipment. Load-haul-dump, LHD loading and mining equipment, created to solve these problems. Its name directly reflects the main functions: loading, transportation and unloading. This is not a replaced by the main tool for transporting materials on underground mines and in tunnel work, which is deservedly called the "iron giant", moving in the depths of the earth.

The main value of this machine is that in an extremely limited and complex space, it performs a cycle of functions, which traditionally requires cooperation of several units of equipment (for example, an excavator and a truck). This significantly increases the efficiency and flexibility of underground work, and also simplifies equipment management at the workplace. More than 75% of underground metallurgical mines in the world use underground loading and delivery vehicles. Their effective and continuous work cycle “Loading - transportation - unloading” is the key to ensuring the smooth flow of the entire underground mining process and increase the volume of production.

Development and technological progress of underground loading machines

In the 1970s, technologies for the production of underground loading and delivery vehicles abroad became quite mature, and production production of products was created. In the 1980s, due to the decline in the global industry of ore mining, competition in the mountain equipment market became still fierce. Many companies engaged in the production of mining and construction equipment have united or merged, optimizing resources to increase competitiveness in the market. The period of the 1980-1990s became the era of rapid development and technological progress of underground loading and derivatives. First, progress in the field of power sources occurred: the engines began to be equipped with electronic diesel control systems (DDEC), which accept various electronic signals from the operator and sensors, accurately adjusting the fuel supply and injection time. Due to this, the fuel consumption of the engine decreased by 3-5%, the acceleration time was reduced, the work during cold start and the quality of the emissions, and the engine service life has also been significantly extended.

Furthermore, significant advances have been made in transmission technology. Electrohydraulic gear shifting and electronic control systems have been developed, ensuring smooth and precise gear shifting while reducing operator effort.

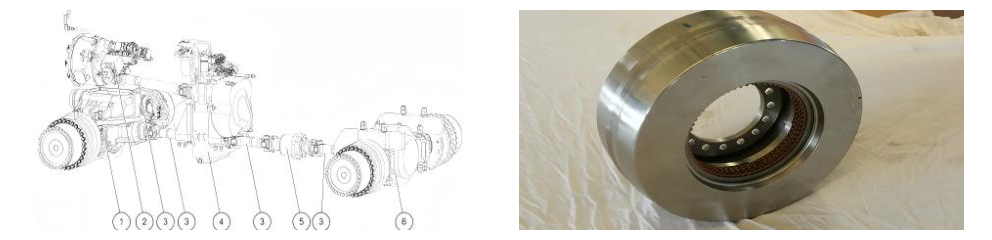

However, a more profound change that had a significant impact on the reliability and safety of equipment was the development of the Drive Axle - a key component of the chassis. To improve maneuverability on slippery and uneven underground galleries, as well as to prevent performance degradation and abnormal tire wear due to wheel slipping, self-locking anti-slip differentials and limited slip differentials in drive axles have been widely researched and implemented. At the same time, a quiet revolution in braking safety occurred - fully enclosed wet multi-disc brakes, due to their superior performance, began to be used in the 1980s, and gradually became the industry standard since the 1990s, laying the foundation for the safe design of drive axles of modern underground LHDs.

Unraveled the secret of the nucleus-the leading bridge: "Security Guard" of the underground loading and delivery machine

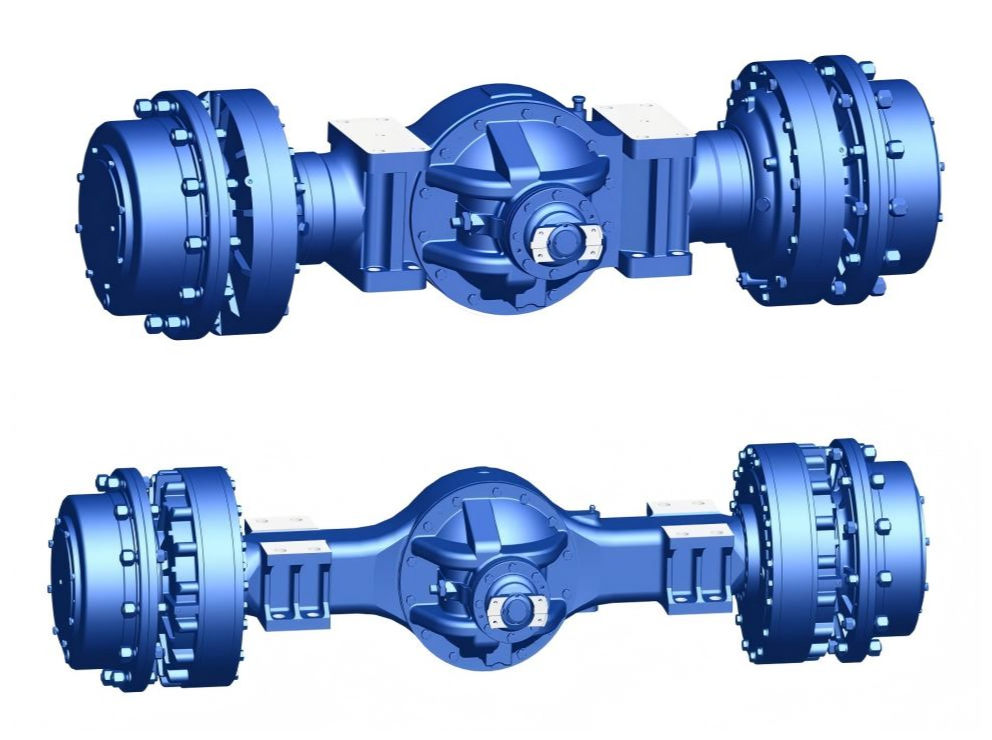

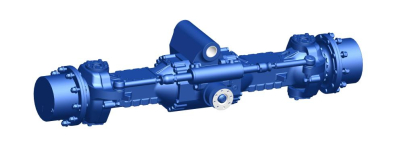

If the engine is the heart of an underground LHD, then the drive axle is its strong legs and anchors. It not only serves as the final actuator for transmitting traction, but also carries the entire mass of the body and load, ensures the movement of the machine, and also performs the functions of turning and braking. In underground galleries with low heights, high humidity, variable slopes and surfaces strewn with sharp stones, the performance requirements of the Drive Bridge reach the limit. Our company has developed a series of LHD Drive Axle products based on a deep understanding of these extreme operating conditions.

1. Maximum load capacity and structural rigidity: against underground loads

During intensive loading and transport of heavy loads, the drive axle of a LHD machine experiences significant shock loads and constant torques. Our company's products feature a bridge frame made of special high-strength steel, manufactured using unique structural reinforcement and precise manufacturing processes. By ensuring low mass, we guarantee minimal deformation of the axle frame under extreme loads, as well as superior bending and torsional rigidity compared to conventional drive axles.

2. Wet brakes and integrated design - a double revolution in safety

The braking system is a vital equipment safety element in underground conditions, to which no compromise cannot be allowed. Based on the development trends of the industry and the aspirations of our company to security, our leading bridges are completely equipped with completely closed wet multi -disc brakes. Compared to traditional dry brakes, they have the following revolutionary advantages:

Excellent Braking Torque and Smoothness: The multi-disc design operates in oil, providing large and extremely stable braking torque. This guarantees smooth and linear braking even on long descents with a heavy load, preventing the risk of losing control.

Intrinsic safety and durability: The fully enclosed design completely isolates the brake from dust, dirt and corrosive gases in underground environments, eliminating the risk of sudden brake failure due to contaminants. Continuous oil cooling significantly reduces thermal loss of efficiency during braking, ensuring long-lasting and reliable brake operation, and its service life is increased several times.

A significant decrease in the risk of open fire: wet brakes operate in conditions when friction between the disks completely occurs in oil isolated from the air, therefore sparks are not formed during friction. This characteristic is crucial in underground conditions with the presence of combustible gases (for example, methane) or a high concentration of dust, as it significantly reduces the risk of fire or explosion caused by the operation of the brake system, and creates an important protection line for the safe operation of the mine.

Most importantly, our braking system innovatively combines travel and parking braking functions, providing a highly integrated and redundant safety design. This “one-stop-in-one” system not only optimizes the spatial layout of the entire bridge and reduces system complexity, but also ensures that in emergency situations (such as hydraulic pipe failure), the system automatically engages emergency braking using the force of a mechanical spring. This achieves the ultimate goal of safety and reliability, providing double protection for the equipment and the operator.

3. The basis of excellent quality is the strategic selection of key components

The long-term reliability of the Drive Axle depends on the quality of each key component. Therefore, we carefully select world famous brands for key parts. These brands have been tested for over a decade in a variety of extreme operating conditions around the world and are renowned for their impeccable precision, superior material properties and exceptional durability. This strategic choice, while increasing initial costs, ensures the longer life of our Drive Axle assembly, minimizes unplanned downtime caused by early component wear, and delivers higher total life-cycle cost to customers.

4.Advanced Differential Control: Overcome Difficult Road Conditions

To adapt to the challenging and variable traction conditions of underground roads (including instances where one wheel is lifted into the air), our drive axles are equipped with anti-slip differential technology. When one wheel begins to slip, the system automatically and quickly distributes torque to the other wheel with sufficient traction. This ensures that the machine maintains strong traction and flotation ability even on muddy, loose or uneven surfaces, which not only improves operating efficiency but also reduces tire wear and power loss.

Clients verification - gaining market trust due to reliable characteristics

Technical parameters and design concepts are objective, but reviews from the first ore mining lines are the most genuine and significant demonstration of product value. From the moment of withdrawing to the market, our series of drive bridges of loading and rental vehicles have been successfully installed on the products of many leading manufacturers of basic equipment and have passed long and intensive tests in real operating conditions on several large underground metallurgical and non-metallurgical mines in the country.

We have received a lot of positive feedback from end clients. The mine director in charge of equipment management noted: “Loading and hauling machines equipped with your company's drive axles have a high utilization rate. Especially in high-load ore mining mode, the drive axle caused virtually no problems. Wet brakes provide sufficient stopping torque and we no longer have to worry about sparks from brake lining wear - making the job of managing fire prevention measures in underground environments much easier. The braking system, which combines travel and parking braking, is safe and reliable - a design that gives us confidence.

A maintenance engineer from a large metallurgical mine assessed the product from a service point of view: “The maintenance period for these mining wet brake drive axles is very long - it is almost synchronized with the equipment maintenance period. This saved us the hassle of making adjustments and replacing brake linings. The use of world-renowned brands for key components has reduced the burden of routine maintenance. The expected lifespan is significantly longer than that of conventional products and the overall cost-effectiveness is very significant.”

These simple and sincere positive reviews from the first lines are the strongest confirmation of the key advantages of our products - large load capacity, high rigidity, safety and reliability of the brakes, long service life. They also motivate us to continuously improve wet brake drive axle solutions for the industry.

Future prospects - a joint movement towards intellectualization and environmental friendliness

With the development of the global ore extraction industry in the direction “Safety, efficiency, environmental friendliness, intellectuality”, the process that cannot be stopped, underground ore mining is faced with the trends of autonomous control, distance management and electrification. This makes higher requirements for underground loading and reservoir vehicles and their key components. Future autonomous underground loading and delivery vehicles will require the leading bridges of high accuracy of the execution of electronic commands, the wider functions of real time monitoring (for example, torque sensors, temperature, vibration) and a reliable ability to exchange data. The electricity trend requires that the leading bridge ensures more efficient energy coordination and integration with the electrical system.

Capitalizing on these prospects, we are actively developing dedicated wet brake drive axles for fully electric and hybrid underground LHD vehicles, exploring more efficient, compact and quiet power transmission solutions to meet the challenges of the future green transition in mining.