What are the consequences of damage to the drive axle?

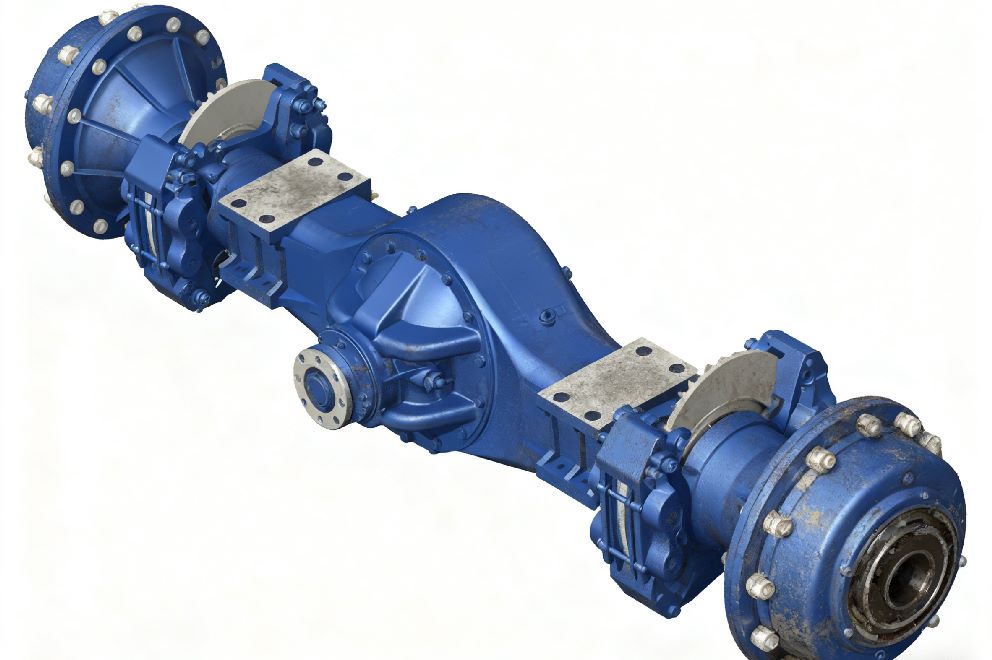

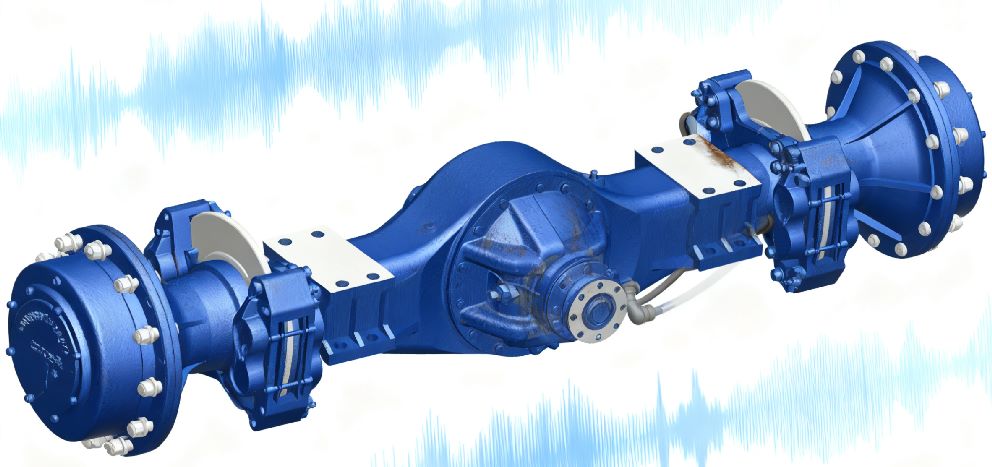

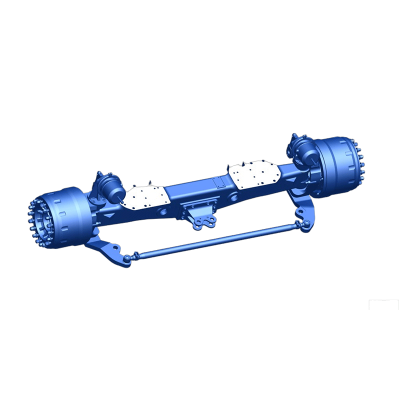

The leading bridge is rightfully considered the “energy bridge” of construction, agricultural and mining equipment. In particular, the leading bridge of construction equipment is a key element of power transmission responsible for the exact transmission of torque from the engine to the wheels. If this critically important component fails, the consequences go far beyond simple equipment downtime - this directly affects the safety of work, slows down production processes and significantly increases operational costs. Below, we consider in detail the warning signals, the cascading consequences of the breakdown of the leading bridge, as well as how quality production allows you to reduce such risks.

1. Warning signals: how to recognize the malfunction of the leading bridge?

Damage to the leading bridge never occurs instantly - the equipment gives clear signals before the full failure. Although symptoms may vary depending on the type of technology, there are common features, especially characteristic of such construction equipment as loaders and wheel excavators:

Symptoms associated with construction equipment (loader bridge, wheel excavator bridge, etc.)

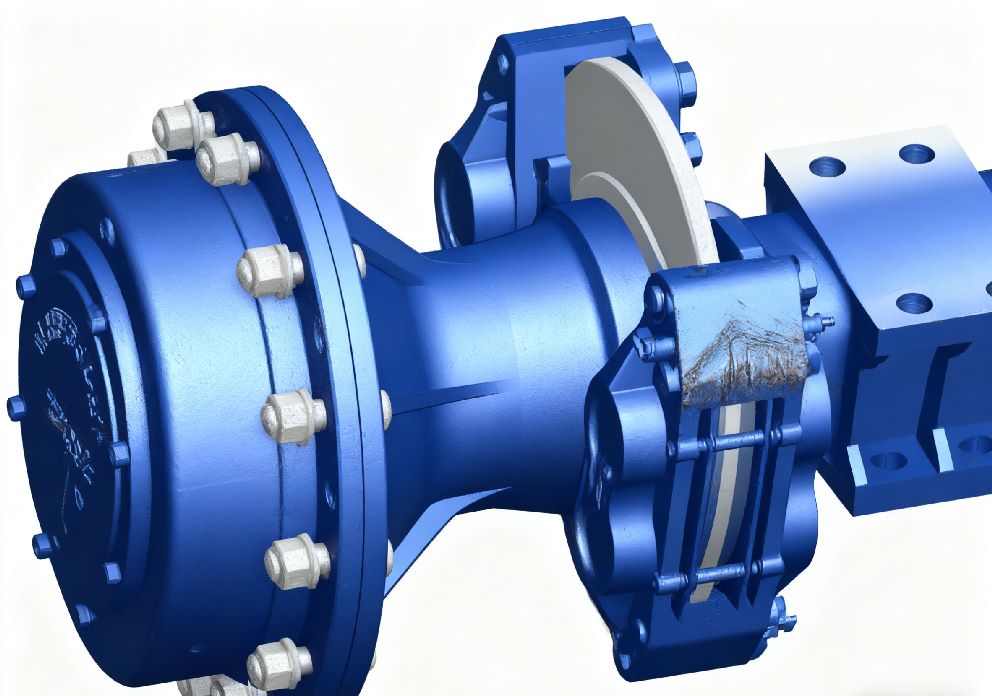

Unusual noises: loud “knocks” or rattle during work often indicate the wear of the differential gears or bearings. For example, a loader bridge, regularly experiencing loads at starting with a load, can publish especially noticeable noises at the beginning of movement. In the case of a wheel excavator, a bridge that works in conditions of frequent switching between traffic and digging modes, wear of planetary gears can be accompanied by a high -frequency screech.

Problems with steering: difficulties in turning or uneven rotation of the wheels are usually caused by a malfunction of the differential blocking. At the wheel excavator, a bridge working in complex areas, the differential jerks can also cause jerks when turning, which seriously reduces the accuracy of operations. For example, the line of the construction equipment of the construction equipment from the Shandong Lutong is equipped with a hydraulic locking of differential, which prevents such problems due to accurate control of oil pressure.

Oil leaks: the presence of oil spots under the bridge indicates damage to the seals, which allows sand, dirt and water to penetrate into the system. In the bridge of a loader working in dusty conditions, the seals wear out faster. However, the leading bridge of construction equipment from Lutong has an improved seal design that effectively protects against pollution, which is especially important for the wheel excavator of a bridge that is often moving through rough terrain.

Symptoms associated with agricultural and mining equipment

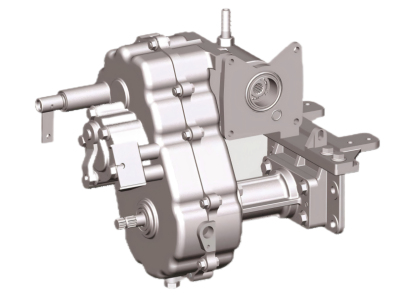

Wheel slippage: If a farm tractor or mining truck loses power when accelerating, this may indicate worn gears in the wheel hub. For example, the Lutong construction equipment drive axle for tractors with 380–430 hp uses an NGW planetary gear system, ensuring stable power transmission.

Severe Vibration: Vibration at high speeds is often caused by axle shaft bending. The drive axle of Lutong construction equipment uses high-strength alloy housings, which eliminates such problems even under heavy load conditions.

2. Cascading consequences of drive axle failure

Ignoring early signs of failure can lead to serious consequences, especially in applications where the drive axle of construction equipment is critical:

Loss of productivity: Drive axle failure results in equipment downtime. For example, in the mining industry, such downtime can cost over $1,000 per day. On construction sites, a broken loader axle or wheeled excavator axle can delay subsequent operations.

Safety risk: Sudden failure of the drive axle can lead to loss of control. For example, a wheeled excavator with a faulty differential axle in a tight work area could cause a collision.

Additional Damage: A faulty drive axle can damage the transmission, tires, and other components. For example, a differential jamming into a forklift axle can cause overload and breakage of the transmission shaft.

3. Prevention: Advantages of Shandong Lutong Products

As a manufacturer with 30 years of experience, Shandong Lutong specializes in construction machinery drive axle, providing optimized solutions for loader axle and wheel excavator axle:

Durable Components: For example, the ZL50 loader axle features Gleason bevel gears, which reduce noise and wear by 40%.

Intelligent production: Automated lines and precision control down to 0.001 mm ensure the reliability of the drive axle of construction equipment.

Adaptation to the task: Special series, such as the heavy-duty loader axle or the lightweight wheeled excavator axle, are designed for specific operating conditions.

4. Operator actions

If you detect signs of a faulty loader axle, wheeled excavator axle, or other equipment, stop the equipment immediately. Shandong Lutong offers global service support and a warranty on all products. To upgrade your construction equipment's drive axle system, contact us—we'll find a solution tailored to your needs.