Here is a car for drilling rock formations

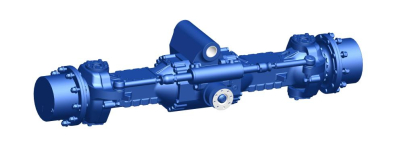

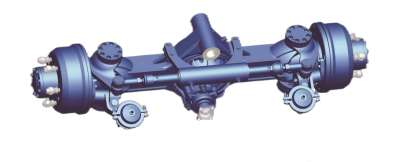

1.The main gearbox uses Gleason spiral bevel gears, which not only significantly increase transmission efficiency but also significantly reduce noise levels during operation.

2.At the end of the wheel, a planetary reduction structure of the "NGW" type is installed.It is known for its compactness and carefully thought-out design.

3.The braking system is equipped with disc brakes with calipers.These brakes generate significant torque, ensuring stable and reliable braking.

4.Thanks to the hydraulic steering assist, the equipment is easily controlled and provides excellent maneuverability.

5.The axle housing, made of solid cast steel, has exceptional load-bearing capacity and high rigidity.

6. This installation is usually installed on 14-16 ton drilling machines, meeting their operational requirements well.

MAIN CHARACTERISTICS:

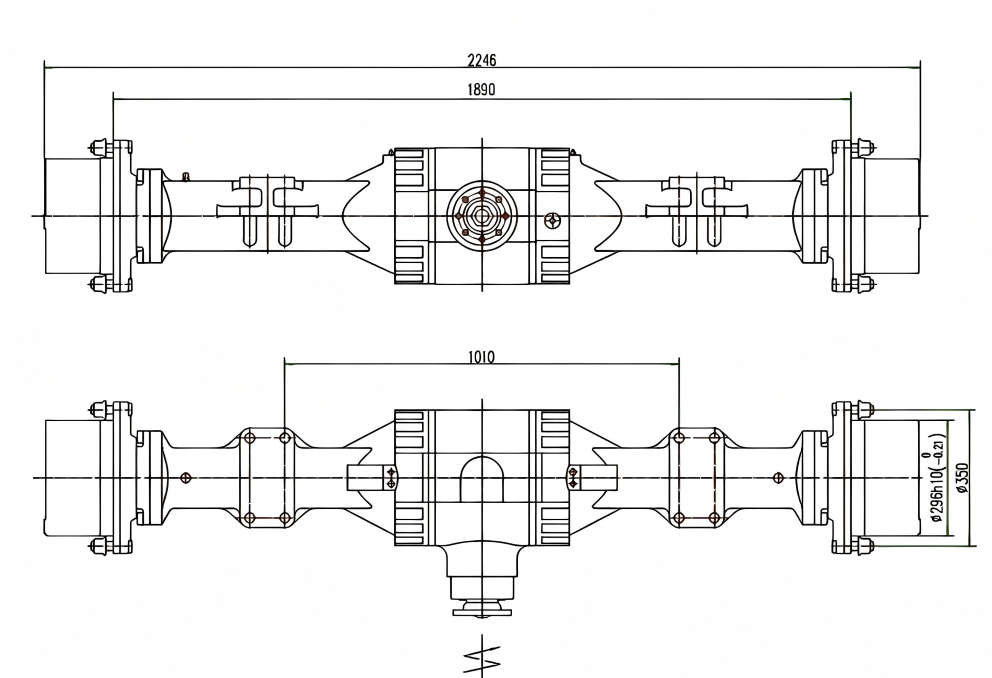

Designed for 14-16 ton rock drilling machines, this equipment is equipped with Gleason spiral bevel gears in the main transmission, ensuring high efficiency in power transmission with minimal noise level.The planetary design 'like NGW' ensures compactness and thoughtfulness of the structure.The disc brake system with caliper provides sufficient torque for reliable stopping, while hydraulic power steering ensures smooth maneuvering.The fully cast steel axle housing, which has excellent load-bearing capacity and rigidity, further enhances durability and performance when performing drilling work in heavy conditions.

Main Technical Parameters:

Overall transmission coefficient |

16.91 |

Maximum torque output |

50000 N.m |

Dynamic load on each axis |

15000Kg. |

Braking torque of one caliper |

21000 N.m |

Brake Oil Pressure |

4Mpa. |

Braking movement |

45-128ml. |

Requirements for oil for the drive axle (API classification) |

GL-5: 85W/90 gear oil (use above -12°C) GL-5: transmission oil 80W/90 (use at temperatures above -26°C) |

Brake fluid |

Hydraulic oil L-HL46 |