Rise of China's Widebody Mining Trucks: Breakthrough in Key Axle Technology Leads New Transformation of Quarry Transportation

Chance time - the growth of Chinese wide -body career dump trucks and a global picture

In the specific sphere of global mining equipment - “large foods, a small market” - a grandiose story of a successful confrontation of “Chinese power” is unfolding. According to the deep report on the industry, published by Changzyan Jianghen (Jiangzhou Jianghen), the total volume of the global market of career dump trucks (including stiff career dump trucks, articulated career dump trucks and wide -body career dump trucks are evaluated about billions of Yuan. This is a high -rical field, dominated by international giants, such as Caterpillar, Komatsu and others.

However, the situation in the market is gradually changing. The report clearly indicates that the demand and proposal of wide -body career dump trucks are mainly formed by the Chinese market. This is a new type of career car developed by Chinese manufacturers, combining the technologies of road heavy trucks and construction equipment. It is precisely focused on scenarios with a payload of 20 to 80 tons, perfectly filling the market niche between traditional hack career dump trucks (with a load of over 70 tons, the price from several million to tens of millions of yuan) and ordinary road samplevs. Thanks to the high ratio of price-quality (price from 500 to 1000 thousand yuan), lower operational and repair and technical costs of SOWIE, the convenience of after-sales maintenance, wide-body career dump trucks quickly became a preferred solution for transportation to medium and small Chinese careers.

Even more enthusiastic is the pace of entry into foreign markets. The leading manufacturers of the industry, such as Lingong Heavy Machinery, Tongli Co., Ltd., Xcmg, Sany and others, bring this “Chinese concept” to the global level, constantly receiving orders in the markets of Russia, Mongolia, Indonesia, Australia and other countries. This is the reflection of the general modernization of Chinese engineering, as well as the historical opportunity, which appeared thanks to the entry of capital costs of the underlying mining industry in a new growth cycle. The report indicates that the total growth rate of capital costs of the ten largest foreign mining companies in the world for the period from 2017 to 2023 amounted to 10.9%, and in 2023 reached 44.9 billion US dollars, which ensured solid support for demand for mining equipment.

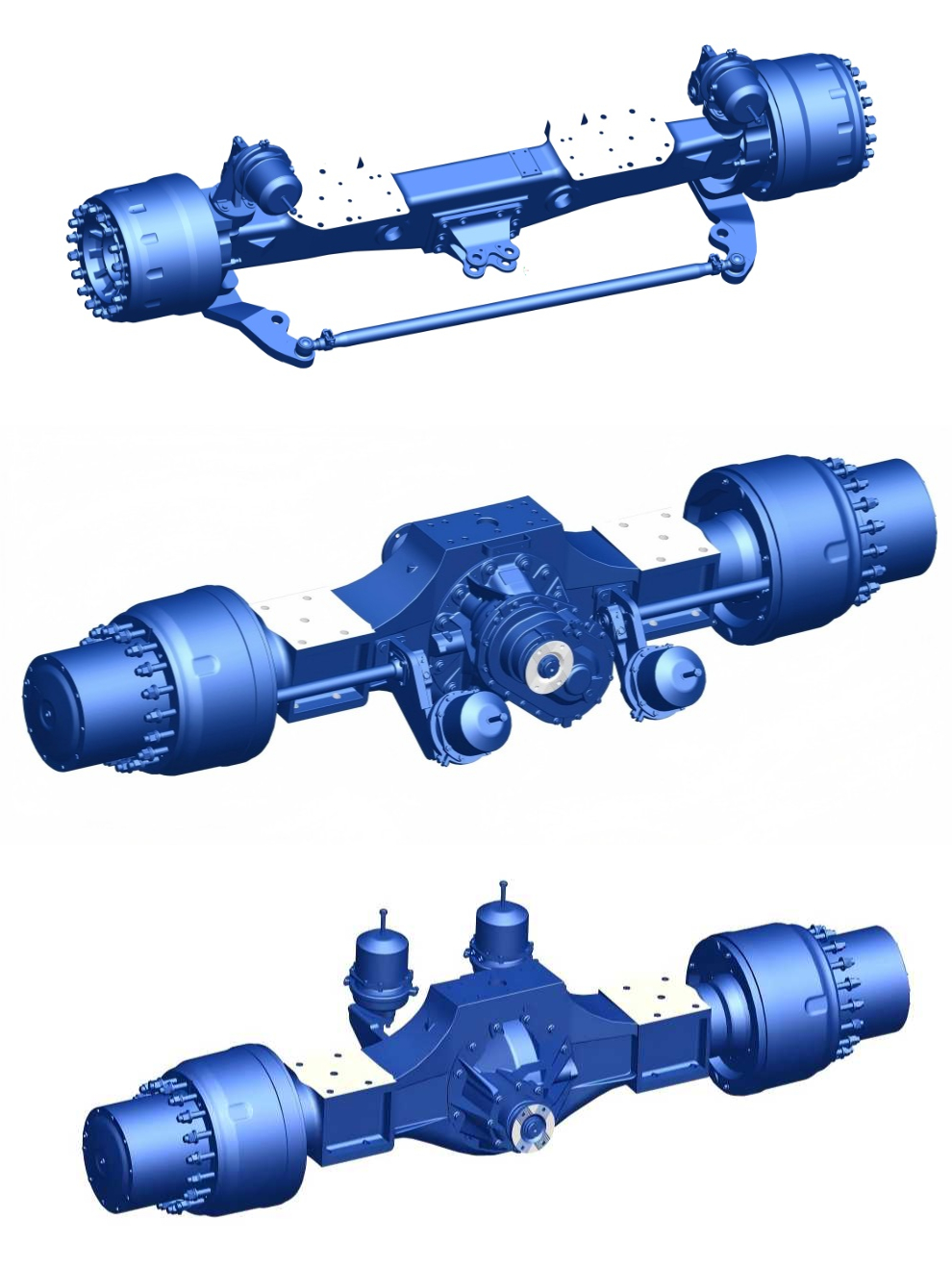

In the framework of this broad perspective, the leading bridge, which is the core of the power transmission system and the supporting design of a wide -body career dump truck, its performance and reliability directly determine the coefficient of use of the entire car, operating costs and the reputation of the brand. If Chinese wide -body career dump trucks continue to master the high market segments and directly compete with giants in the international market, then overcoming technical barriers in the field of key components and creating a world class of the leading bridge in assembly of a compulsory point for the entire industrial chain that cannot be missed.

The main challenges are the technical barriers of the leading bridge under the harsh operating conditions

Careers are undoubtedly a “final test field” for construction equipment. Here, the leading bridge of a wide -body career dump truck is faced with challenges that significantly exceed those who experience ordinary commercial cars and approach extreme:

1. Extreme dynamic loads and blows: with heavy descent along an uneven road on a career, the leading bridge experiences not only static loads, but also constant shock loads. Each uneven road becomes a severe test for the strength of the design of the bridge case, its stiffness and fatigue strength of the seams. Traditional constructive solutions are often subject to premature failure in such operating conditions, for example, deformation of the bridge case, cracking of seams, etc.

2. Constant highly loaded work: When operating on quarries, they strive for maximum efficiency, so the equipment often works around the clock 24 hours a day. This means that toothed gears, bearings and other transmission elements inside the leading bridge should work at high power density, withstanding long -term, continuous wear and thermal loads. Any fact of fatigue of the material, failure of lubrication or insufficient thermal protection can lead to a decrease in the efficiency of transmission or even catastrophic malfunctions.

3. The omnipotent influence of the environment: there are often a lot of dust on quarries, and in the rainy season the territory becomes dirty and mucus. These small particles and moisture, which are inside the leading bridge, sharply accelerate the wear of gears and bearings, spoil the lubricating oil, and create serious pressure on the compaction system. At the same time, extreme heat in northern quarries makes high requirements for low -temperature plasticity of materials, elasticity of sealing elements and viscous oil characteristics.

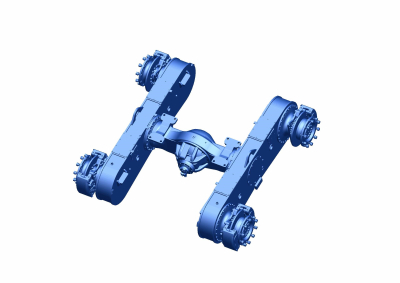

4. Complex requirements for the distribution of power and control: the full leading bridge assembly includes the front rotary bridge, the intermediate bridge and the rear bridge. Among them, the intermediate bridge, acting as the center of distribution of power, should not only fulfill its own drive function, but also effectively transmit power to the rear bridge. On roads with low grip (for example, dirty, inclined), the ability to quickly block the sliding leading bridge using interdosseary differential locks and accurately transfer the torque to tires with sufficient grip is a key indicator of the productivity of the leading bridge that directly affects the cross -country ability and safety of the entire car.

These challenges clearly pose challenges for universal design solutions. Only a drive axle developed using direct engineering and specifically adapted to quarry operating conditions can support the growth of Chinese wide-body mining trucks—and this is the focus of our technical research and development.

Solving technical problems is the engineering philosophy behind the new generation of quarry drive axles.

Based on a deep understanding of the above calls, our company, combining more than thirty years of experience in the development and production of heavy automobile bridges, introduced a new generation of systems of the leading bridge of a wide -body career dump truck in the collection. Our goal is not just a replacement of existing solutions, but a reduction of the standards of high -performance leading bridges for quarries through a number of innovation in basic technologies.

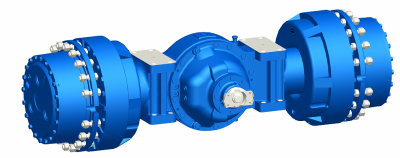

1. The basis: reliable safety of the nucleus due to the super -strength structure of the bridge case is the "ridge" of the leading bridge. We abandoned universal structures and applied the technology of topological optimization based on the finite elements method to optimize the design of the bridge case, ensuring the distribution of material in critical zones with maximum loads. The use of high -strength steel in combination with advanced technologies of casting and heat treatment allowed the bridge body to maintain plasticity while achieving a high strength limit. During the bench tests, our bridge case successfully passed millions of test cycles for vertical bending fatigue, exceeding the industry standards, simulating shaking and blows equivalent to several full cycles of the car. Its fatigue strength has reached an international advanced level, which eliminates the risk of safe incidents due to the failure of the structure on the root.

2. The core: maximum effectiveness due to the high -precision transmission of the gears of the intermediate and rear bridges is the “heart” of the leading bridge. We have applied advanced design and high -precision manufacturing technologies, thanks to which the accuracy of gears reached an industry leading level, providing a more smooth gearing, below the noise level and a longer service life.

3. Protection: the fight against environmental corrosion due to the comprehensive compaction and effective heat voltage, we have developed a multi -level protection system for the external effects of “active + passive” seal for the leading bridge. In critical places (for example, on spindles of wheels connecting surfaces), combined seals from multi-leaf oil seals and o-shaped rings are used, and a unique labyrinth design to protect against dust, effectively blocking dust and dirty water inward, was developed. To solve the problem of thermal regulation, we determined the internal channels of the lubricant in the bridge case, increasing the heat voltage area, which guarantees that the temperature inside the leading bridge, even with long -term highly loaded work, remains in the optimal working range. This prevents the failure of the lubrication and wear of the components due to high-temperature oxidation of the oil and a decrease in its viscosity.

Practical tests - extreme checks in Silinguole

Laboratory data is a peak of theoretical capabilities, and the land on a career is the final examiner. Our system of the leading bridge of the wide -body career dump truck in the collection is successfully installed on the wide -body quarry dump trucks of a certain model of the leading manufacturer Sany Heavy Industry and passed several months of practical tests in one of the large open coal quarries in Mongolia Silinguole, known for its harsh operating conditions.

Careers in Silinguol are characterized by severe winter cold, stiff summer heat, a strong veterus with sand and uneven roads - this is an ideal test field for the integrated productivity of equipment. The testing machine performed key transport tasks, the average duration of daily work exceeded 20 hours, the transportation distance was large, and the load was constantly at the maximum nominal level.

During the tests, we closely cooperated with the car manufacturer and the end consumer, carrying out comprehensive monitoring of the work of the leading bridge. For the entire period of tests, despite the continuous heavy load, strikes and temperature changes, the leading bridge assembly (including the front bridge, the intermediate bridge and rear bridge), provided by our company, did not have a single case due to malfunctions associated with the quality of the product, the use coefficient was 100%, which earned a high estimate from the brigade of maintenance on the spot.

Drivers noted that the power transmission of the car was direct and efficient, and in areas with lifts at heavy load, the car showed excellent results. The function of differential locking had a quick reaction, effectively preventing the sliding of the wheels in separate dirty areas and increasing the effectiveness of the passage. A comparison of preliminary data showed that thanks to the effective transmission system and low honeymental resistance, the car had the best fuel consumption indicators with the same volume of transported cargo compared to similar models. At the same time, excellent reliability directly reduced the potential costs of repair work and losses from downtime, which emphasized the advantages of economy on the entire life cycle.

These successful tests in typical operating conditions not only proved in practice that the system of the leading bridge of a wide -body career dump truck in the collection of our company easily copes with the most severe conditions of Chinese quarries, but also allowed us to collect valuable data for further optimization and updating of products. They indicate that our technology of the leading bridge is completely ready to support Chinese wide -body career careers of high -class dump trucks in their competition in the global market.

The joint creation of the future is a new stage of movement to intellectualization and green transformation

Currently, the Chinese industry of career dump trucks enters in the era of the revolution, combining "an increase in size, electrification and intellectualization." According to the GGII Institute of High Technologies (High-Tech Industry Research Institute), in 2023, the sales of Chinese electric car-carrier dump trucks exceeded 1,500 units, by 2025 it is expected to exceed 2500 units, by 2028-3500 units, and a promising market volume can reach 40-60 billion Yuan. At the same time, large mining companies, such as China Energy Group, Huaneng Group and others, are actively promoting pilot projects to use unmanned career dump trucks.

Looking at the future, the strategy of our company is clear and firm: we will continue to deepen the work in the key area of the leading bridge of a wide -body career dump truck and promising to develop the following areas:

Intellectual update: development of the platform of the intellectual leading bridge, deep integration of sensors and control systems to provide an intellectual and reliable solution at the executive level for unmanned career dump trucks. Global service: Together with Chinese car manufacturers entering foreign markets, we are building a global supply and service network, guaranteeing timely technical support of our products in any corner of the world.

We clearly understand that only the possession of key technologies will allow us to move stably and far away. In the future, our company will actively develop advanced regions, such as electric drive bridges for new energy cars, intellectual controlled bridges and others, closely cooperating with Chinese car manufacturers in order to jointly promote the comprehensive technical renewal of Chinese careers and won more voting and influence for “Chinese -made” in the global market of high -class mining equipment.