Shandong Lutong: Customized Drive Axle Solutions for Global Construction Equipment Manufacturers

It is expected that by 2025 the volume of the market for building equipment for construction equipment in China will reach 45 billion yuan, while the share of bridges for heavy equipment will increase to 55%, and the demand for leading bridges for agricultural machinery will grow annually by 8-10%. Thanks to many years of technical developments and accurate understanding of the market, Shandong Lutong is betting on “individualization” as a key competitive advantage, offering effective and reliable solutions for leading bridges to manufacturers of construction, agricultural and mining equipment around the world. Recent successes in individual service projects in both domestic and foreign markets confirmed its powerful technical capabilities and a high level of service.

Narrow specialization in individual solutions for world manufacturers

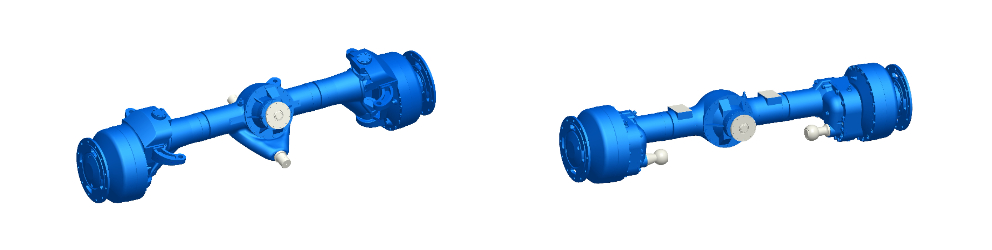

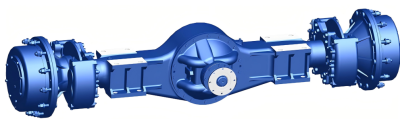

As a professional manufacturer of leading bridges, Shandong Lutong is well aware that the requirements for the characteristics of leading bridges differ significantly depending on the field of application and the region. Therefore, the company has created a special individual service team that works with customers at all stages - from discussing requirements and design to production and delivery - and has already successfully implemented individual projects for several large manufacturers of equipment in China and abroad.

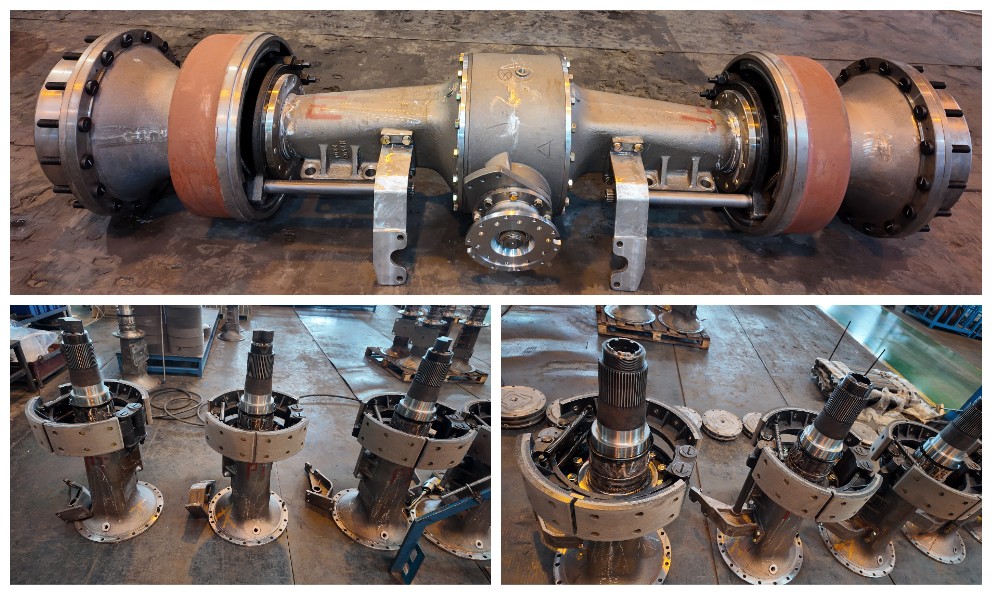

In the Russian market, Shandong Lutong has developed a leading bridge of a 400 hp tractor. For the Tractor Plant in St. Petersburg, taking into account local conditions for the operation of agricultural machinery. This bridge was specially optimized for working in low temperatures and high loads: materials with improved characteristics were selected, tightness and efficiency of power transmission were increased, which ensures stable and efficient operation of the tractor in extreme conditions. The decision was highly appreciated by the customer.

The company also developed the LT400C tractor drive axle for another renowned Russian manufacturer. Thanks to its innovative design and customized performance, the axle is perfectly matched to the customer's tractor powertrain, strengthening Shandong Lutong's position in the customized agricultural machinery solutions segment in Russia.

For road construction equipment, Shandong Lutong has developed the leading bridge of the JC98 grader, taking into account the features of operation in Russia. Given the frequent turns and constant loads when aligning the soil and the construction of roads, the team enhanced the design of the rotation mechanism, applied wear -resistant and frost -resistant materials for gears, and also increased the impact resistance of the bridge case. This guarantees accurate control of the grader and durability even when working on frozen and rocky soils. The decision successfully passed multi -stage tests and has become the key component of the customer technique.

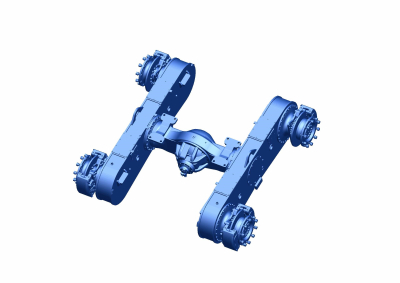

In the domestic market, Shandong Lutong also achieved significant success, setting up driven leading bridges for leading Chinese special equipment manufacturers such as Sany and Shantui. Given the high loads and complex operating conditions of construction equipment, the company increased the bearing capacity, impact resistance and durability of bridges. These solutions not only meet the requirements of customers, but also increase the competitiveness of their technology, which makes Shandong Lutong a reliable partner for special equipment manufacturers in China.

Technical team - the basis of an individual approach

The key factor in the success of individual solutions is technical support. The SHANDONG LUTONG team has a team of experienced specialists and engineers with more than 10 years of experience in designing and developing leading bridges. Within the framework of individual projects, the team quickly responds to customer requests, analyzes the operating conditions, the parameters of the power system and the key characteristics of the equipment to offer the optimal solution. The use of 3D modeling, of of course and other advanced technologies allows you to repeatedly check and improve the design.

In addition, the company introduced a continuing training system so that specialists remain aware of the latest trends in the field of leading bridges. Today, the team has implemented dozens of individual projects, solving many technical problems, which ensures high quality service.

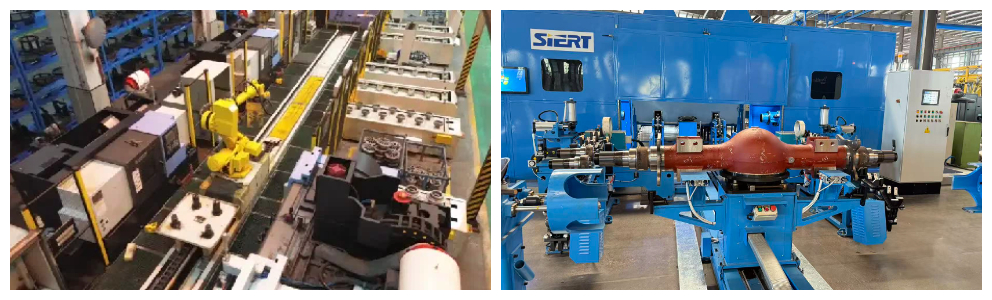

Modern equipment is a guarantee of quality and efficiency

To ensure precision and consistent quality, Shandong Lutong has invested in modern production and testing equipment, creating automated workshops. CNC machining centers, precision grinding machines, and heat treatment units are used in production, enabling the manufacture of drive axle components with high precision.

Quality control includes comprehensive bench testing, leak testing, endurance testing, and other tests. Each customized drive axle undergoes thorough inspection before shipment, ensuring 100% compliance. The implementation of an intelligent production management system accelerates order fulfillment and helps customers bring equipment to market faster.

Shandong Lutong will continue to develop its customized solutions business by investing in technology, equipment, and process optimization. The company aims to offer equipment manufacturers worldwide even more efficient and reliable customized drive axles, contributing to the development of the construction and agricultural industries.