Lutong Heavy Industry has commissioned a new automatic axle welding line.

Shandong Lutong Heavy Industry Machinery Co., Ltd. I recently announced that its new welding automatic line intended for welding the pennies of loaders and tractors has been officially commissioned. An important initiative indicates that the company has carried out a large -scale transition from traditional methods of production to intellectual and high -precision production in the production of leading bridges and laid a strong basis to improve the quality and introduce innovative technological processes in the production of leading leaders bridges.

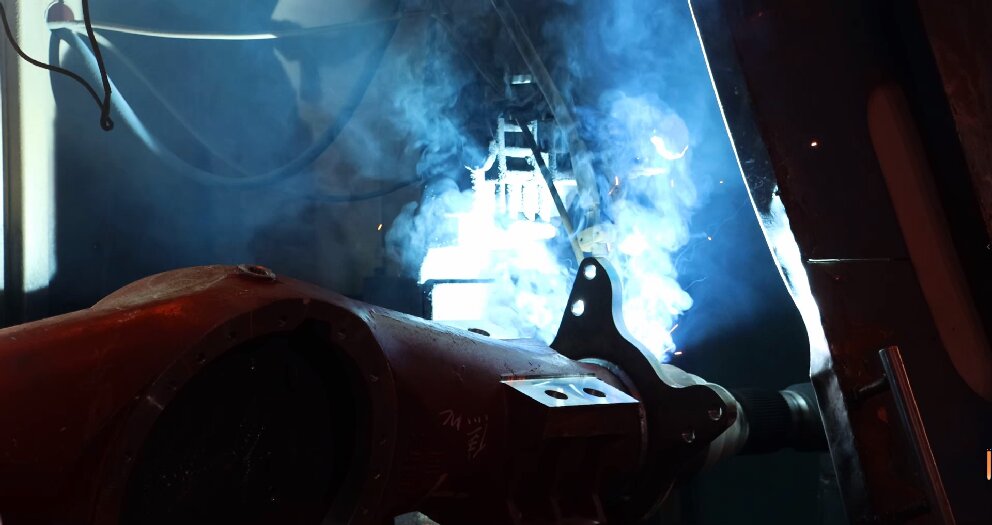

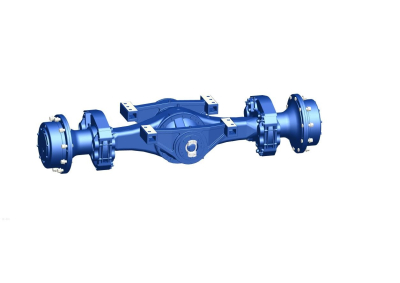

The quality of the leading bridge, which is the main component of construction equipment, directly depends on the service life and reliability of the entire machine. The long time is the precision control of the welding process of the leading bridge in the industry. Automatic welding line put into operation by Lutong Heavy Industry this time provided a qualitative jump in the process of welding the leading leaders thanks to the complete automation of control and the closed data processing cycle. The production line combines ABB robots, intellectual logistics systems and visual recognition devices that allow you to fully automate the entire process - from the loading of the workpiece and accurate positioning to welding and molding, as well as quality control. This is not only significantly increases the efficiency of the leading bridge, but also provides homogeneousness, but also provides homogeneity And the reliability of products due to the accurate management of the technological process.

In the process of manufacturing the leading bridge, the alignment of the axis housing and the mounting plate on the part of the wheel is a key factor affecting the operational characteristics of the product. Non -welding automatic line controls the error error in a very small limits using step -by -step pressing and hydraulic control system with a closed contour, which significantly increases the efficiency of transmission and the lifting capacity of the leading bridge. Welding directly led to the optimization of the performance of the product. The leading bridge demonstrated excellent fatigue durability and stability of the structure during bench tests, which effectively solves the problem of additional loads caused by insufficient accuracy in the traditional welding process.

Intellectual modernization: Technological innovations in the production of leading bridges

Reasonable modernization of the production of leading bridges is the inevitable tendency of the development of the industry. The New Automatic Lutong Heavy Industry Automatic Line has provided a high -quality breakthrough from the “human and machine interaction” to “full automation” due to the intellectual system without interference without the intervention of a person throughout the process. In the previous production model, despite the implementation of robotics while welding the leading bridge, Still required manual participation in the movement of the workpiece and calibration of the position. An intellectual transformation of the intellectual transformation, the new production line completely eliminates the influence of the human factor on the quality of the leading bridge, ensuring high accuracy and consistency of the manufacture of each product.

The intellectuality of the welding process of the leading bridge is manifested not only in the degree of automation, but also in improving data management. Data monitoring in real time and adaptive tuning, a new production line can actively prevent defects and ensure stable quality of welding of the leading bridge. This is a production model based on data, ensures a reliable guarantee of long -term reliability and durability of the leader Bridge. In addition, the introduction of intellectual systems also made the production process of leading bridges more monitoring, providing reliable support in quality management and after -sales maintenance.

Quality stability: the main guarantee of the reliability of the leading bridge

The stability of the quality of the leading bridge is directly related to the overall performance of the construction equipment. The Lutong Heavy Industry New Automatic Automatic Line provides an almost zero quality of welding of leading bridges due to the triple protection mechanism. In the first, closed workplace and an effective dusting system ensure the environmental cleanliness of the welding process of the leading bridge; Secondly, the protective gas flow regulation system ensures the stability of the welding process; And, finally, the high repeatability of the accuracy of the positioning of the robot provides a technical guarantee of the stability of the drive. welded seams on the axes. The comprehensive use of these measures made it possible to significantly reduce the porosity when welding the leading bridge, and the quality of welds reached the highest level in the industry.

Improving efficiency and impact on the industry: a new standard in the production of leading bridges

The commissioning of the new automatic welding line Lutong Heavy Industry has established a new performance standard for the production industry of leading bridges. Significant reduction of the production cycle and a significant increase in the efficiency of the equipment of the equipment fully reflect the positive impact of intellectual production on the efficiency of the leading bridge. At the same time, the reduction in the cost of the quality and number of redeems once again confirm the efficiency and practicality of the new The production line. Putting the efficiency of the leading bridge not only brought direct economic benefits to the enterprise, but also served as a guide for the technological progress of the entire industry.

The reliability of the leading bridge is one of the most important concerns of users of construction equipment. The adherent to the accurate control of the technological process and the intellectual quality management of the new production line significantly increased the service life and the capital repairs cycle of the leading bridge. This is not only reducing the costs of users for maintenance, but also increases the competitiveness of the products of the leading bridges of Lutong HeAVY Industry in the market. In the conditions of rigid competition in the industry, the reliability and durability of the leading bridge have become key factors that help enterprises to gain customer trust.

Technological modernization of the production of leading bridges has a huge impact on the development of the industry. The company of commissioning the new automatic welding line Lutong Heavy Industry not only improved the quality of its products and the technical level, but also indicated the development of the entire industry for the production of leading bridges. Intephanticity, accuracy and flexibility became inevitable trends in the production of leading bridges, and the development of the leading bridges, and the development of leading bridges, and Lutong Heavy Industry is an active leader and practitioner in this area. It is expected that in the future, thanks to the stable operation of the new production line, the company will further strengthen its competitive advantages in the market of leading bridges and will provide customers around the world with better products and services.

The level of manufacture of a leading bridge, which is the main component of construction equipment, directly depends on the performance and reliability of the entire machine. The Lutong Heavy Industry automatic welding line is all up to the operation of the company's many years of production in the field of production of leading bridges. A reliable guarantee of the production of leading bridges, but also makes an important contribution to the transformation and modernization of Chinese production, making it intellectual and high -tech.