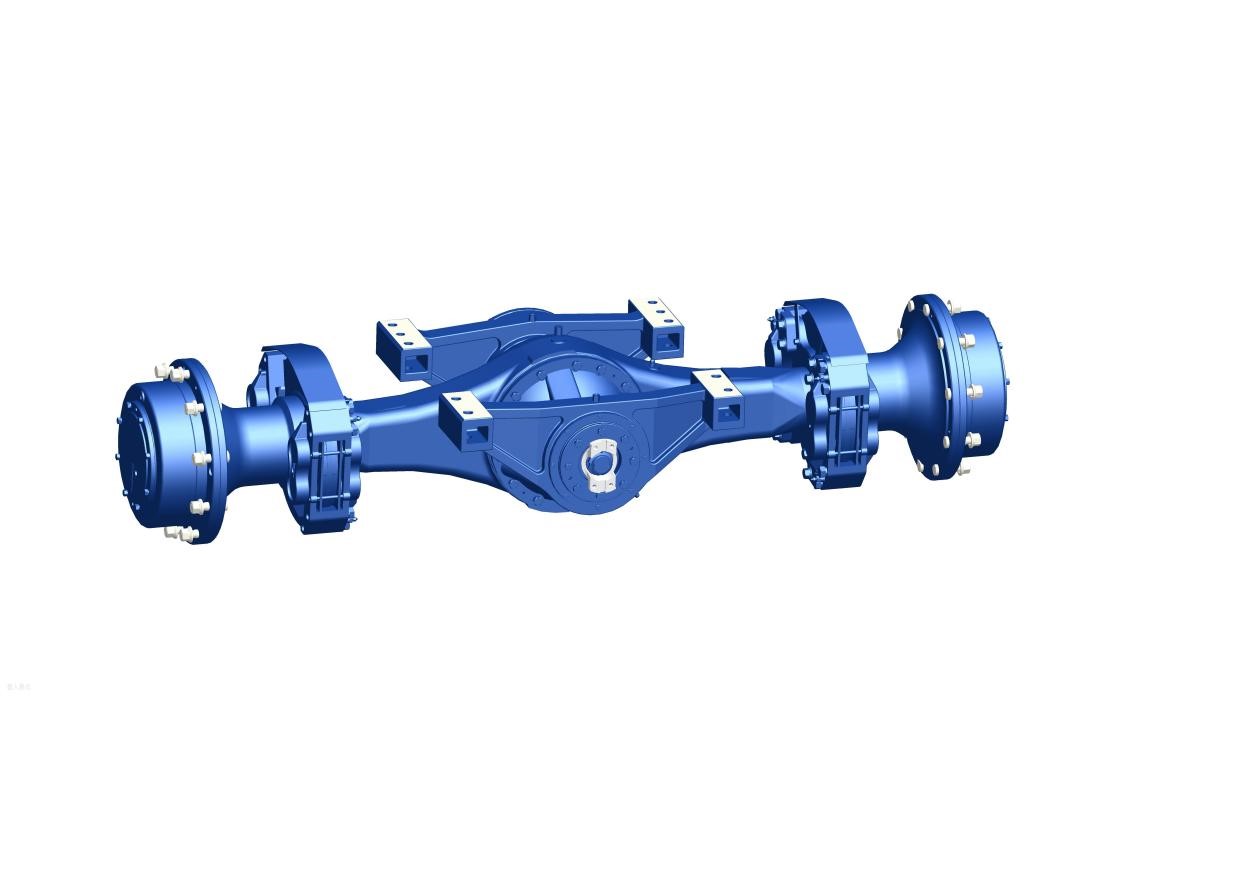

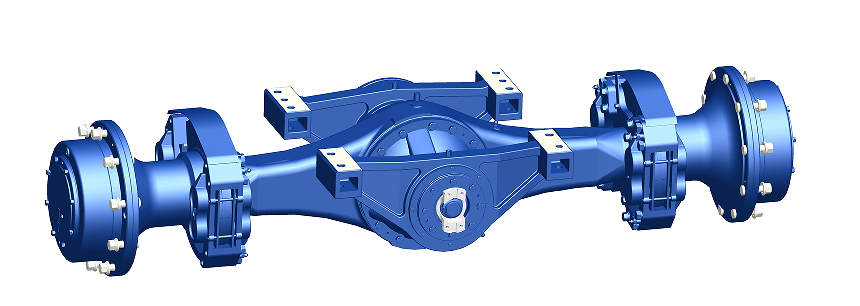

Loader swivel axle

1. High-class international benchmarking

2. Provided supplies to a number of leading equipment manufacturers

3.Products can be customized according to customer requirements

4. Professional technical support

5. A large number of goods in stock

Introduction:

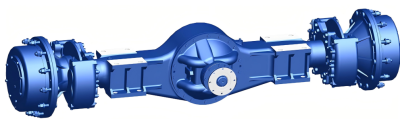

The pumping bridge of the loader is a key component in the field of engineering equipment, specially designed to increase adaptability to working conditions in the field. Its outstanding structural feature lies in a compatible connecting structure with a hinge frame - the leading bridge can make oscillatory movements up and down relative to the frame, and in combination with a multi -sized metal swinging frame, effectively extinguishes shock loads caused by the irregularities of the road surface. Such a dynamic balancing structure ensures the stability of the loader when working on uncleaned surfaces, such as mineral production or infrastructure construction, and also maintains constant contact of the drive wheels with the ground, significantly reducing the likelihood of breaking materials during transportation.

In practice, a pumping bridge of a loader can provide adapted solutions to transmit power depending on the requirements of the working environment, combining the necessary traction and efficiency for various operating conditions. This helps the loader to maintain the stability and effective contact of the drive wheels with the surface when working on unexpressed roads, reducing the loss of materials and the risks of equipment failure. In addition, its design takes into account the convenience of everyday maintenance and can be adapted to the standard needs of loaders of various carrying capacity.

Specially designed for loaders of the ZL50 series and has many advantages. The design of the gearbox includes a two-stage decrease in the transmission, with the possibility of choosing a conventional differential or a self-locking differential (No-Spin LSD). Equipped with disk brakes with calipers that provide a high brake moment and reliability. In addition, the modular design not only facilitates everyday maintenance, but also allows you to adapt the product to individual requirements of loaders of different carrying capacity.

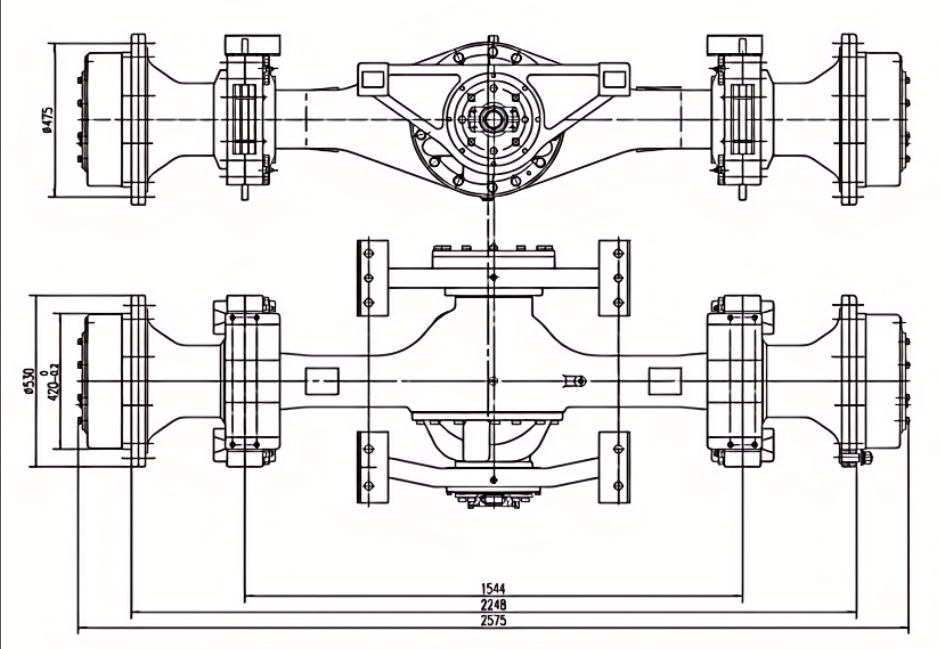

The main technical parameters:

Common gear ratio |

22.853 |

Maximum input torque |

5100N.m |

Load on one bridge |

27000Kg |

Brake system oil pressure |

10MPa |

The working volume of a one -sided brake |

40-70ml |

The moment of braking of one side |

26000N.m |

Flower requirements for the leading bridge (API classification) |

GL -5: 85W/90 transmission oil (at temperatures above -12 ° C) GL -5: 80W/90 transmission oil (use at a temperature above -26 ° C) |

Brake fluid requirements |

Hydraulic oil L-HL46 |

The advantages of the company:

A full cycle of ensuring the value of the product of quality:Strict control at all stages of production of the production process, from the choice of raw materials to the production of finished products, strict quality standards are observed. Materials that meet the requirements of engineering equipment are used, and proven processing technologies increase the wear resistance of key components. The finished products undergo multifaceted tests to ensure stable operation in typical operating conditions, which guarantees durability and compliance with basic requirements.

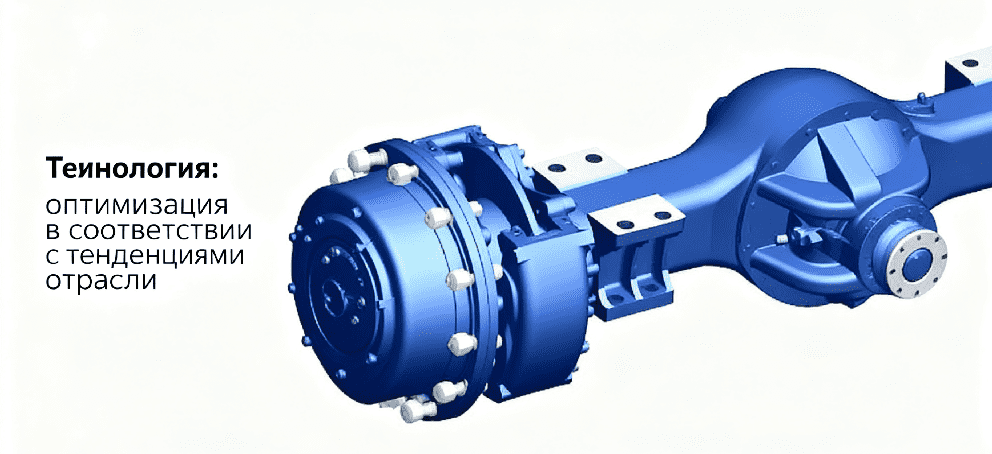

Technical support:Optimization, in accordance with the trends of the industry -aspect on experience in the field of power transmission in engineering equipment, we constantly improve the technology of the pumping bridge of the loader, integrating practical industry solutions and feedback from users. This improves indicators such as power transmission and stability, and also takes into account future needs for technological updates, helping customers increase the overall equipment productivity.

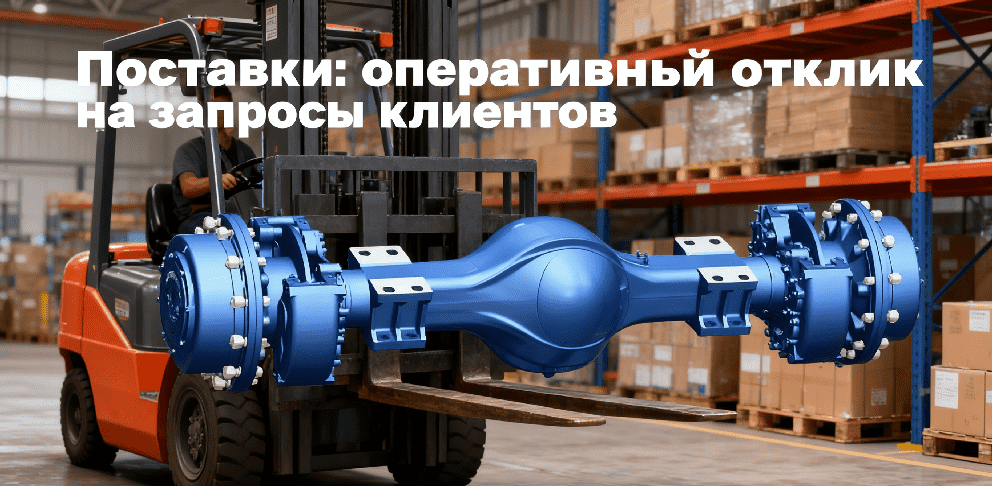

Logistics and deliveries:The prompt response to customer requests has created an effective system for managing the supply chain, combining the resources of reliable suppliers of components and rationally planning production. This guarantees standard manufacturing time and supply efficiency. Depending on the needs of the customer, we provide timely deliveries, whether standard orders or urgent requests, thanks to the optimized system of logistics cooperation.

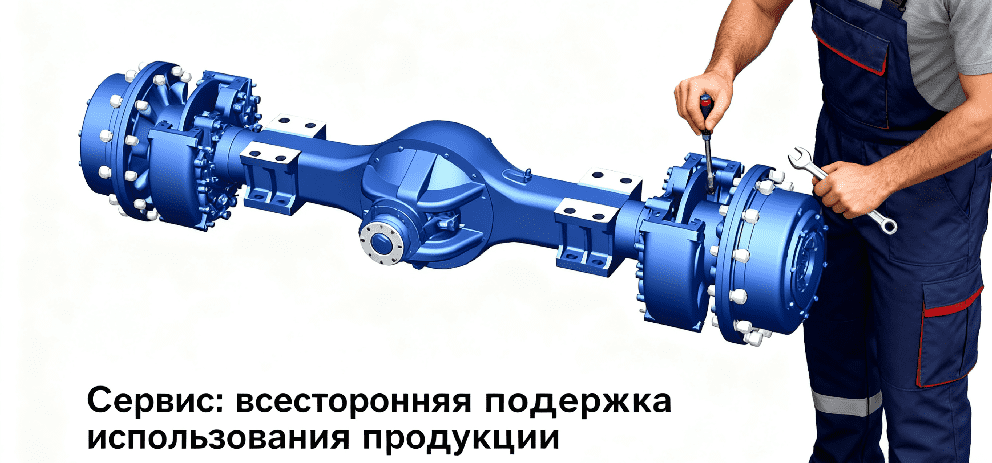

After -sales service:Comprehensive support for the use of product of product is provided to customers after saving support throughout the life cycle of the product, including clear warranty obligations. Our professional service team quickly responds to requests and needs for repair, providing recommendations for maintenance of equipment and instructions for eliminating faults. In addition, we support the supply of often in demand by spare parts, which allows you to quickly provide the necessary components and minimize the downtime of equipment due to breakdowns.