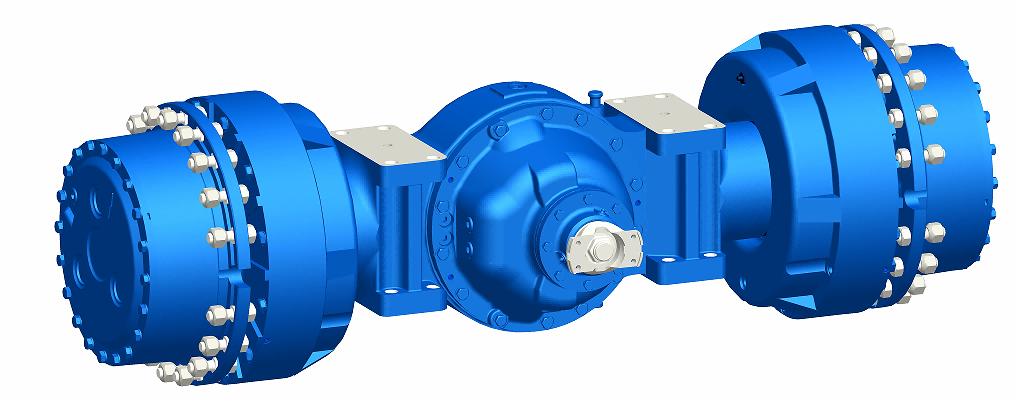

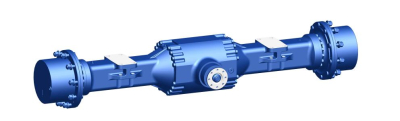

Here is a 3-cubic underground screper

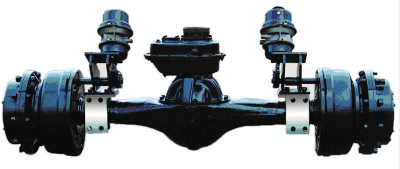

1.This system, equipped with a Limited Slip Differential No-Spin (LSD), provides 100% traction control on dirty surfaces, completely preventing wheel slip.

2.The integrated disc brake system with a wet disc combines the functions of working and parking braking into a single mechanism (POSI-STOP), ensuring reliable operation.

3.Floating seals at the ends of the wheels are specifically optimized for long-term operation in conditions of increased humidity and sludge formation and exhibit enhanced durability of the seals.

4.The most important components supplied by globally certified Tier-1 suppliers ensure reliability over a long service life in accordance with industrial cycle requirements.

5.The steel cast axle, more suitable for two reduction gears, provides optimal load distribution and torque transmission efficiency.

6. Suitable for 3 cubic underground scrapers.

Introduction:

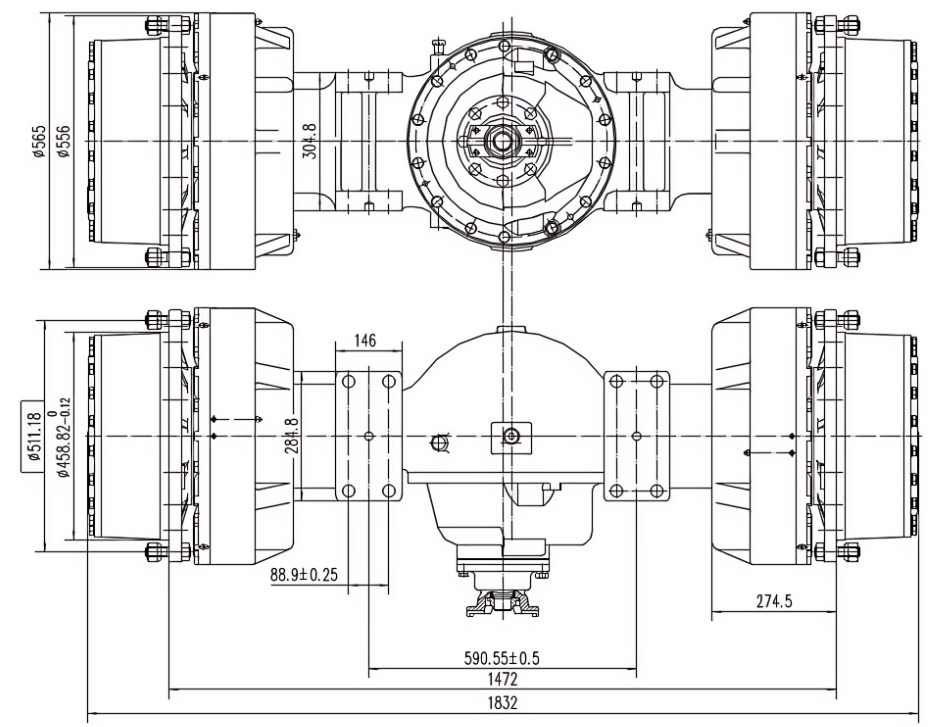

This underground scraper axle is designed for 3-cubic underground scrapers and has a durable solid cast steel axle body.The front axle is equipped with a No-Spin differential with limited slip (LSD), and the wheel systems use a dual-action braking system with springs and hydraulic unlocking (POSI-STOP) combined with floating sleeves.This design ensures optimized adaptability and increased operational reliability, specifically designed for working in complex underground mining conditions.

Main Technical Parameters:

Overall overall gear ratio |

26.118 |

Maximum input torque |

4290 N.m |

Load on one bridge |

19050Kg. |

Brake Design |

POSI-STOP Spring Brake/Hydraulic Pinch Brake/Multi-disc Wet Brake/Strong Cooling |

Oil pressure during braking |

10.4Mpa. |

Single braking capacity |

163.9ml. |

Single braking moment |

20000 N.m |

Requirements for oil for the drive axle (API classification) |

GL-5: transmission oil 85W/90 (use at temperatures above -12 ° C) GL-5: transmission oil 80W/90 (use at temperatures above -26°C) |

Brake Cooling Oil and Remove Brake Oil |

Hydraulic oil L-HL46 |