Hangzhou Gear visited the factory to discuss the production technology of drive axles for construction equipment.

Join forces: industry leaders come to attract attention and chart a new collaboration plan

Recently, the Chairman of the Board of Hangzhou Advance Gearbox Group Co., Ltd., a leading domestic high-quality transmission system company, and his technical team visited our company to in-depth study and exchange technical opinions. This high-level visit is not only a recognition by industry authorities of our company's more than 30 years of experience in field of drive axles, but also marks a general increase in the level of strategic cooperation between the two sides in the field of major components of construction machinery. During the visit, the guests visited our company's intelligent production workshop, national-level testing center and scientific research base, and fully confirmed our company's achievements in the field of advanced technology of drive axles, upgrading intelligent production and entering the international market.

The high technical performance and in-depth exchange of views during this visit are rare in our company's overseas cooperation in recent years.As a leading gear enterprise in China, Hangzhou Gear Group's products are widely used in many important fields such as shipbuilding, construction machinery and wind power.This in-depth, high-level exchange between the two sides not only reflects the industry's recognition of our company's technical strength, but also heralds the possibility of deeper cooperation in the field of comprehensive data transmission system solutions in the future.During the two-day visit, technical personnel from both sides held several rounds of in-depth discussions on current trends in drive axle technology development, changes in market demand, and future areas of cooperation.

As a high-tech enterprise with more than 30 years of professional R&D and production experience, our company has always paid special attention to technological innovation and improving the product quality of construction machinery drive axle series.From its initial line of individual products to a complete product system covering numerous fields such as construction machinery, mining machinery, agricultural machinery, forestry machinery, and more, the company has grown into one of the leading drive axle manufacturers in the country, with the most comprehensive product line and strong technical capabilities.The visit to leading companies in the industry once again confirmed our company's professional strength and influence in the drive axle industry, and laid a solid foundation for deeper strategic cooperation in the future.

A testament to strength: 30 years of technology accumulation has become a benchmark in the industry, and innovation drives development

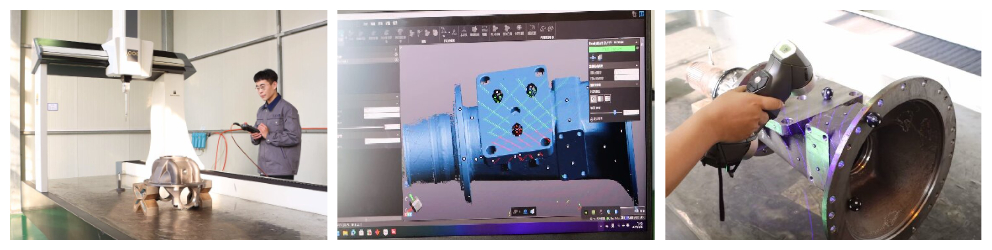

During the visit and exchange of views, the guests learned more about our company's full-scale quality control system - from the purchase of raw materials to the delivery of finished products.In the precision machining workshop, dozens of advanced machines from Germany and Japan perform precision machining of the main components of the drive axle, and precision manipulators work together with high-precision machining centers to ensure the precision machining of each component of the drive axle; In a comprehensive laboratory covering an area of 2,000 square meters, advanced equipment such as ultrasonic flaw detectors and 3D coordinate detectors ensures thorough inspection of products.

Currently, our company has more than 50 official patents, including more than 10 patents for inventions.The company invests 5% of its sales revenue in research and development annually, and the technology center brings together a research and development team of more than 30 people, including a special expert on State Council subsidies.The combination of these technologies allows the company to provide a full range of solutions to various customers – from structural design and equipment optimization to control system integration.

Product Matrix: Diversified layout to meet global needs, technology is the future

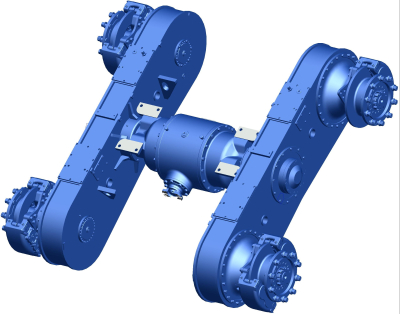

After more than 30 years of development, our company has formed a complete product line, covering ten series and more than 100 models.In the construction equipment industry, drive axles, transmissions, and torque converters for wheel loaders have been among the top three in terms of domestic market share for five years running due to their high reliability and fuel efficiency.Among them, the 5-ton drive axle loader series products have become a benchmark in the industry due to their excellent performance, and the cumulative sales volume has exceeded 100,000 units.

The drive axles of wide-body mining dump trucks and face scrapers, developed for mining equipment, have successfully replaced a number of imported products due to their superior load capacity and durability. In the field of agricultural machinery, the innovative use of high-strength alloy steel for the manufacture of drive axle housings for powerful tractors has increased fatigue life by more than 10%. field of forestry equipment, the innovative modular design of the drive axle assembly of forestry machines has reduced maintenance costs by more than 30%. Of particular concern is the fact that the company has taken a leading position in the production of new drive axles for power construction equipment, and the electric forklift drive axle assembly designed for such companies producing electric construction equipment equipment like Borreton is supplied in batches. The main gearbox of this series adopts contour gear and the planetary gear adopts gear grinding technology. The transmission efficiency is more than 5% higher than the traditional drive axle, and the noise level is reduced by 20 decibels. At the same time, the company is actively promoting the research and development of new drive devices such as wheel drives, which will provide more advanced walking solutions for the next generation of high-performance construction equipment."We are not only a drive axle manufacturer, but also a walking system solution provider vehicles." Introducing the product line, the company's CTO emphasized: "From traditional mechanical drives to the latest electric drives, from standard products to deep customization, we always strive to create maximum value for our customers." Our goal is to become the world's leading provider of gait solutions."

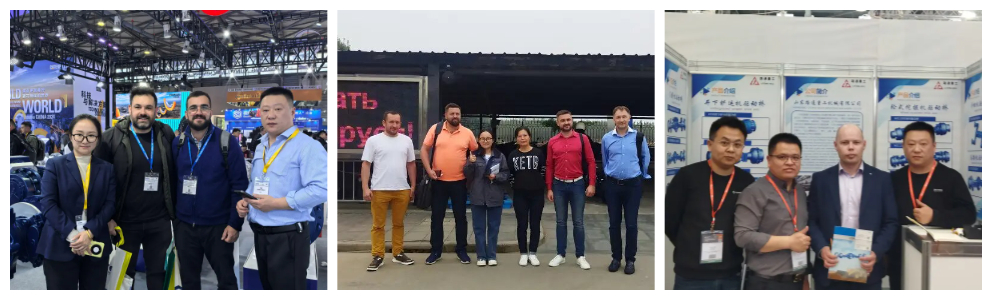

Market recognition: hundreds of customers at home and abroad make a common choice, and quality earns trustThanks to excellent product quality and precise market positioning, our sales strategy has enabled us to simultaneously promote and provide all-wheel drive solutions in both the domestic and international markets.In the domestic market, the company has established long-term and stable cooperative relationships with leading construction machinery manufacturers such as Sany Heavy Industry, Liugong Group, Longgong Holdings, Xiagong Shares, Shantui Construction Machinery, etc., and has been regarded as an "excellent supplier" by many customers over the years.Among these, the collaboration with Sany Heavy Industry is particularly close. The company is not only the primary supplier of drive axles for Sany loaders, excavators, and other products, but also participates in the simultaneous development of many new Sany products.

In terms of internationalization and expansion, the company has seized the opportunities of the "Belt and Road", focused on emerging markets such as Russia and Belarus, and established stable supporting relationships with well-known companies such as PTZ, UMG and AMKADOR.The motor grader's drive axle, which was specifically designed for operation in Russia's extremely cold conditions, was field-tested for three winters and achieved a 98.5% utilization rate, which was highly praised by customers.This drive axle, specially designed for working in extreme cold conditions, adopts a special low-temperature material formula and sealing technology, which can work normally under extreme conditions of -45℃, and its performance is completely superior to similar European products.The company's products are currently exported to more than 30 countries and regions worldwide, with annual exports accounting for over 40% of the company's sales.To better serve international customers, the company has opened offices and technical support teams in key markets such as Russia and Belarus to provide local after-sales support.This deep market penetration strategy has led to further growth of the company's influence in the international market.The company's general manager stated at the stock exchange: "We always focus on consumer demand, every order is a promise, and every product is passed on by word of mouth.It is this concept that has earned us the long-term trust of more than 100 clients worldwide.In the future, we will continue to improve the two-wheeled "technology + service" model to provide customers with better products and services."

Cooperation Prospects: Create a new future for core components and work together for mutually beneficial development

The high-level visit of Hangzhou Advance Gearbox Group representatives has laid a solid foundation for future in-depth cooperation between the two parties.During the discussion and exchange of views, both sides held in-depth discussions on the development of efficient next-generation data transmission systems, the application of intelligent manufacturing technologies, and the joint development of the international market, and reached intentions for cooperation in many areas.According to the consensus reached by both sides, in-depth cooperation in the future will be carried out in the following key areas: first, joint exploration of key transmission system technologies; the second is cooperation in market development, sharing customer resources and providing comprehensive transmission system solutions. and finally, supply chain collaboration to reduce costs and improve market competitiveness through joint procurement.In his closing speech, the Chairman of the Board of our company emphasized that the company will take this opportunity to further increase investment in R&D and innovation, improve the global service system and continuously improve product competitiveness.In the next three years, the company plans to build a new smart chemical plant, introduce advanced international production lines, and increase the annual output of drive axles by 50%. At the same time, it will focus on introducing advanced technologies such as intelligent drive axles and electric axle drive to provide better products and services to customers around the world.“We firmly believe that through in-depth cooperation with outstanding powertrain companies in China, we will definitely create a new model for the development of core components in China.The Chairman of the Board confidently stated, “In this era full of opportunities and challenges, we will continue to uphold the core values of “innovation, quality and service” and work hand in hand with our partners to jointly promote the transformation of “made in China” into “created in China.”"