How to calculate the weight of the drive axle? Shandong Lutong: your guarantee of professionalism

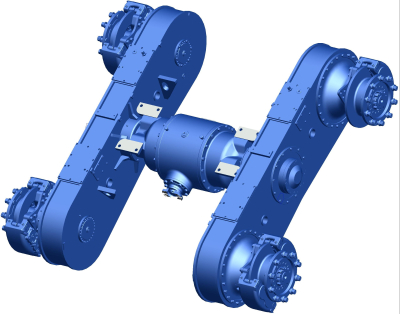

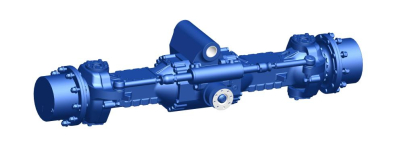

In the production and adaptation process of construction, agricultural and mining equipment, the weight of the drive axle is not just “weighing data”. It directly impacts equipment stability (such as balancing a wheeled excavator's center of gravity when turning), fuel efficiency (controlling loader energy consumption during heavy duty operation) and subsequent maintenance costs. Shandong Lutong, as a specialized manufacturer with 30 years of experience in the field of drive axles, not only helps master scientific calculation methods, but also embodies "precise calculation" into "reliable product" through comprehensive technical and manufacturing capabilities. In particular, in such key categories as drive axles for loaders, drive axles for construction equipment and drive axles for wheeled excavators, a complete service system has been formed from calculation to delivery.

I.AKey steps for calculating drive axle weight: Shandong Lutong simplifies complex processes

The drive axle design includes the housing, power transmission system, bearing assemblies, and other components. The calculation requires simultaneously considering "data accuracy" and "adaptation to operating conditions," but without the need for complex formulas. Drawing on accumulated experience, Shandong Lutong breaks the process down into three easy-to-follow steps and provides exclusive data and technical support:

Step 1: Accurate collection of basic parameters - Shandong Lutong provides a "ready-made database"

The calculation is based on two types of key data, the absence of any of which may lead to deviation of the results:

Equipment parameters

Drive axle parameters

Step 2: Component-by-component calculation – Shandong Lutong controls “error” with technology

The drive axle weight is the sum of the weights of its main components, calculated using the principle of "disassembly → calculation → summation." Shandong Lutong uses professional tools to ensure accuracy at every stage:

Bridge weight

Drive system weight

Weight of auxiliary components

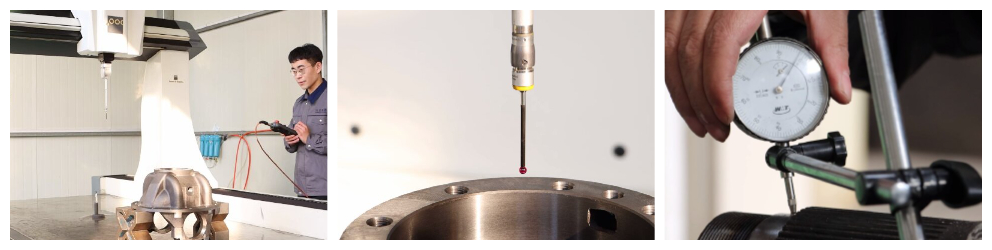

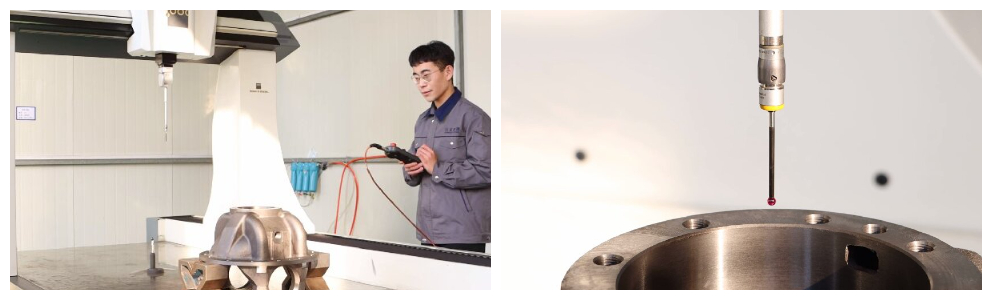

During the calculation process, we use 3D scanners to “check the actual dimensions of components”, controlling the calculation error within ±2% - this is an accuracy that is difficult for ordinary manufacturers to achieve, and one of the key reasons for the superior adaptability of Shandong Lutong drive axles.

Step 3: Dynamic Testing Based on Operating Conditions - Shandong Lutong Ensures Accuracy with "Testing"

After calculating the base weight, adjustments must be made based on actual equipment operating conditions to avoid "paper projects." Shandong Lutong ensures the results are implemented through double verification:

Adjustment of operating conditions

Experimental verification

2. Shandong Lutong: will not only “calculate” but also “build a good bridge”, and ensure the quality of the entire process.

For customers, “accurate calculation” is a prerequisite and “efficient use” is the goal. Shandong Lutong has developed a comprehensive guarantee system, from technical team, production equipment to quality control and delivery, to ensure that each drive axle (whether it is a loader drive axle or a wheeled excavator drive axle) meets “design weight = actual weight” weight = adapted weight.”:

Professional technical team: basis for calculation and design

The company has formed a development team of more than 30 people, 15 of whom have more than 10 years of experience in designing drive axles.

For the loader axles, the team optimized the "heavy-load weight balancing algorithm" to match axle weight to load capacity, avoiding "excessive weight that increases energy consumption or underweight that affects strength."

For the wheeled excavator bridge, a “lightweight design model” has been developed, which guarantees maneuverability when turning, keeping the weight within reasonable limits and reducing the fuel consumption of the equipment during operation.

No matter what axle weight you need to calculate, the team can provide a "custom" interpretation of the parameters and calculation guidance, and even adjust the calculation model to suit your individual requirements.

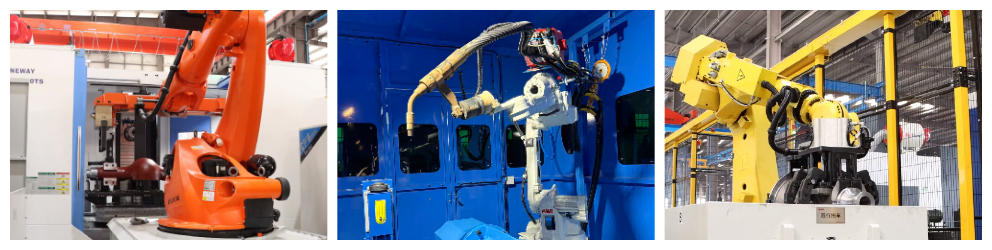

Modern production equipment: transforms "calculation accuracy" into "manufacturing accuracy"

Even the best calculations require precision equipment for implementation. Shandong Lutong's manufacturing facility is equipped with numerous high-precision machining machines, covering the production of all drive axle components:

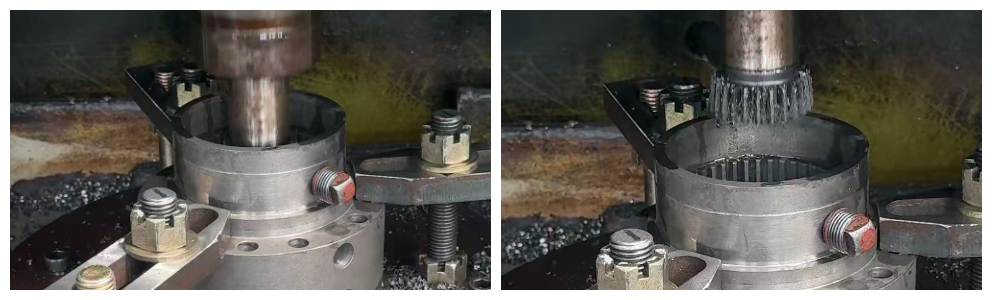

CNC gear shaping machines: When processing final drive gears, the tooth shape error is ≤0.01mm, which ensures that the weight of the gear matches the design value and avoids weight fluctuations due to tooth shape deviations.

Three-coordinate measuring instrument: As a core testing equipment, it can perform full-size scanning of key components such as axle housings and gears, accurately record detailed parameters such as wall thickness and pitch, ensure that the volume of components accurately matches the design value, and eliminate weight errors caused by dimensional deviations from the original.;

Multiple automatic lines: Using "distributed weight tracking system", each production line synchronously records the weight data of each component during the assembly process - from bearing installation to axle assembly, each step of weight change is uploaded to the system in real time, and once the error range is exceeded, it immediately stops and adjusts, which not only guarantees the accuracy of single drive weighing axles, but also ensures parallel and efficient production of several categories of equipment (for example, drive axles for loaders and drive axles for wheeled excavators).

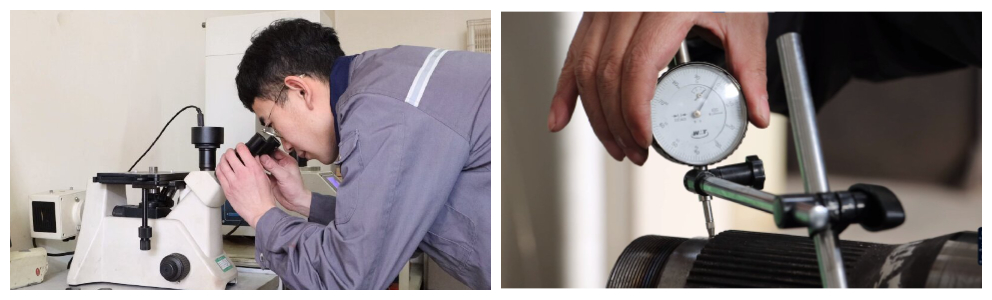

Strict quality control system: from “specified weight” to “specified quality”

Shandong Lutong has implemented a three-level quality control process from raw materials to semi-finished products to finished products, which checks not only the weight but also the performance characteristics to ensure that each drive axle meets national standards.

Raw material testing: For incoming steel, gear blanks, etc., the material composition and density should be determined by spectral analyzer to avoid weight deviation due to impurities.

Semi-finished product inspection: For every 10 axle housings and 5 gears, 1 part is taken out for “destructive weighing”, such as cutting the axle housing to measure the actual wall thickness and check whether it matches the design value.

Finished Product Testing: In addition to using a high-precision strain gauge to determine the weight of the entire bridge, it is also necessary to conduct more than 20 tests, such as 1 million bench fatigue tests (simulating 5-year operation), leakage tests (0.8 MPa pressure without leakage), and noise level tests (operating noise level does not exceed 85 decibels). In particular, the forklift drive axle must also undergo additional “severe-duty impact testing” to ensure compliance in both weight and performance.

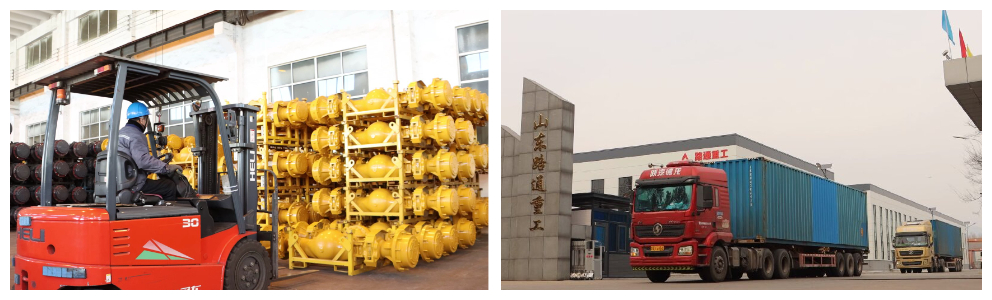

Efficient delivery service: allows you to “receive the goods after payment”.

Regular drive axle models of loaders and wheeled excavators are in sufficient quantity in stock and can be shipped within 72 hours; for customized construction machinery drive axles (such as special models for mining), thanks to the “parallel R&D-production process”, the delivery cycle is 30% shorter than the industry average. In addition, each product will be accompanied by a “weight parameter report” indicating the calculated value, the actual weighing value and the adapted equipment model, so that you can directly use it when assembling equipment.

3.Choose a suitable partner to make the drive axle weight calculation “easier”.

For equipment manufacturers or maintenance companies, the ultimate goal of drive axle weight calculation is to find products of “suitable weight and reliable quality”. Shandong Lutong can not only help you simplify the calculation process and provide accurate data, but also use 32 years of manufacturing experience to solve the problem of “accurate calculation but poor quality product” - as of 2025, we have serviced more than 100 equipment manufacturers with an annual production capacity of 50,000 sets, of which the share of loader and wheeled excavator drive axles in the loader and wheeled excavator drive axles market is firmly in the leading position in the industry.

Whether you are calculating the weight of the drive axle for a certain equipment or you need to purchase a high-performance drive axle of construction equipment, Shandong Lutong can provide one-stop service of “parameter selection - weight calculation - product customization - after-sales service guide”, so you don't need to go shopping. move from “data calculation” to “product search” and back again.