Amkodor visits to deepen cooperation on the development of a grader drive axle

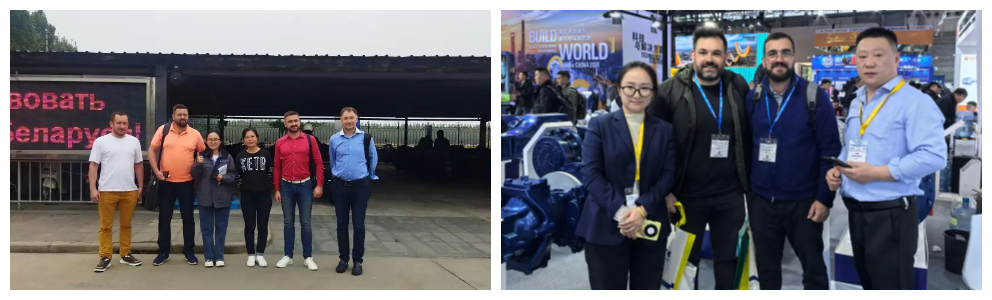

International clients visited for inspection, demonstrating the enterprise's global influence

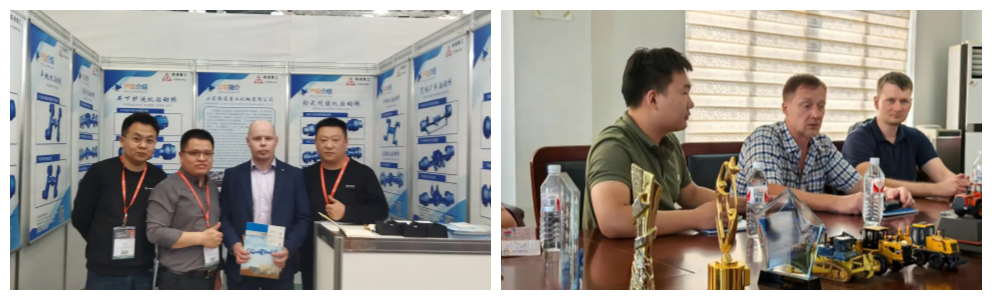

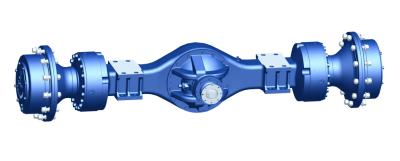

Recently, a delegation from an important client from Belarus, Amkodor, made a special visit to our company for an in-depth inspection and technical exchange. During the visit, customers not only highly appreciated the quality of our grader drive axles and loader axles, but also expressed a strong desire to deepen cooperation. In addition to the already market-tested products, the parties also reached preliminary agreements on cooperation on new products, such as the wheeled excavator bridge. This visit clearly demonstrated the excellent competitiveness of our products in the international market, as well as the technical strength of "Made in China" in the field of key components.

The delegation visited our intelligent processing workshop, assembly line and product testing center. During the inspection, customers were especially interested in the manufacturing process of the grader drive axle, from welding and forming the axle body to precision machining of the gears, from checking the quality of components to assembling and commissioning the entire axle. Each stage was studied in detail. The client's technical experts noted: "We have personally seen your company's strict quality control system, which gives us confidence to deepen our cooperation."

As a company specializing in the development and production of drive axles for construction machinery for more than 30 years, we always consider product quality to be of vital importance. The visit of Belarusian clients is not only recognition of the quality of our products, but also confirmation of the overall competitiveness of the enterprise. During the technical exchange, the parties discussed in detail the adaptation of products to the special operating conditions in Belarus, which provided valuable data for further optimization and modernization of products.

Proof of Strength: Superior Quality Wins International Trust

During the technical exchange, Amkodor customers shared practical data on the use of our drive axles. According to their information, graders equipped with our bridges have shown outstanding results in infrastructure projects around Minsk. Over 2,000 hours of operation, the key components of the drive axles did not have a single breakdown, and the level of equipment availability exceeded 98%. Especially in extremely low temperature conditions, specially optimized seal systems and low-temperature gear oil ensured normal starting and stable operation of the equipment at -35°C.

“The durability of these drive axles is impressive,” said a representative of the Belarusian company. “In the most challenging wetland conditions, the product's performance and reliability completely exceeded expectations. This was the main reason for our return visit and desire to expand cooperation.”

Our production system combines smart and lean technologies. In the machining shops, high-precision robots and machining centers from Germany and Japan produce key drive axle components. In automated welding areas, robotic systems ensure the highest quality of every weld. On assembly lines, technicians use advanced torque control systems to ensure every bolt is accurately tightened. These advanced manufacturing and processing technologies ensure outstanding performance and reliability in every product.

Our testing system deserves special attention. In addition to standard checks for size, hardness and cleanliness, each drive axle undergoes multi-stage testing: idle, load and leak tests. This strict system guarantees the quality of our products.

Product Benefits: Innovation Delivers Superior Performance

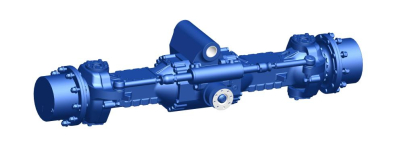

The grader drive axles that we supply to Amkodor were specially designed to take into account the climatic and operational characteristics of Eastern Europe. This series of axles features a reinforced body structure that increases torsional rigidity by 25%, effectively resisting shock loads on uneven surfaces. The optimized gear system ensures transmission efficiency of more than 90%. Wet braking systems have high braking torque and resistance to overheating, which is especially important for working on long slopes. These technical advantages have allowed graders with our bridges to show outstanding results in infrastructure projects in Belarus.

Regarding forklift axles, our company has made a number of improvements based on local conditions. For the cold winters of Belarus, the lubrication and sealing systems have been optimized, which ensures normal starting and operation at -35°C. Additionally, reinforced dust seals extend service intervals in mining environments. According to customer reviews, loaders with our axles have a 30% lower failure rate compared to similar products.

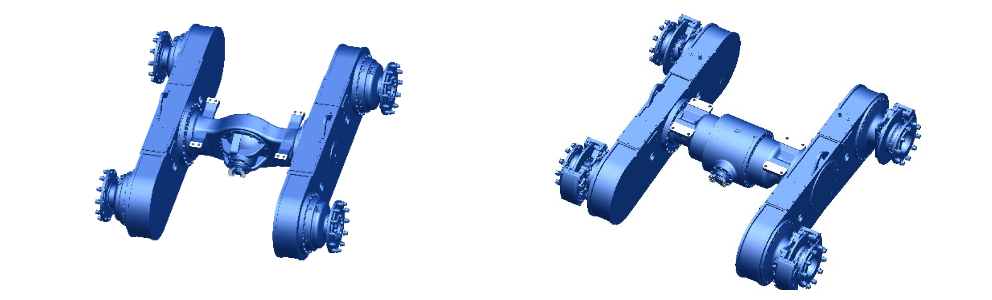

Based on successful previous cooperation, Belarusian customers expressed a desire to expand the range, especially interested in our axles for wheeled excavators. During the technical exchange, engineers from both sides discussed parameters, performance requirements and adaptation to local conditions in detail.

The wheeled excavator axle series is another strong product of our company. These axles cover models from 8 to 15 tons and offer a variety of configurations to choose from. The latest models use a modular design, providing compatibility and flexibility. They feature wet brakes, limited-slip differentials and differential locks to handle the toughest conditions. Innovative cooling and lubrication systems guarantee reliability during continuous operation. These benefits aroused great interest from the client.

History of cooperation: from product recognition to strategic partnership

Our first collaboration with Amkodor began five years ago. Back then, the client purchased graders with our drive axles, and their outstanding performance caught their attention. They were particularly impressed by the axles' reliability in winter projects, where the equipment withstood extreme temperatures and heavy loads. The client found us through the information on the equipment's nameplates, and thus began our international partnership.

The first direct delivery included a small batch of loader axles—10 units for testing. After the construction season, the products earned the approval of end users, and the scope of cooperation gradually expanded: from loader axles to grader axles, from component supplies to technical collaboration. Our company became the key supplier of drive axles for this client.

It is especially worth noting that our technical team visited Belarus twice for service. We promptly resolved emerging issues and made improvements to products taking into account local conditions. This customer-centric approach strengthened trust between the parties.

Spreading a reputation for quality: indirect exports show results

Our products enter international markets not only through direct export, but also as part of equipment from Chinese manufacturers. Thanks to its excellent quality, it has won positive reviews abroad. Last year, a Belarusian client independently found us based on the information on the equipment plate and expressed a desire to cooperate. Now our products have a stable customer base in Belarus, Russia, Kazakhstan and other countries of the “One Belt, One Road”.

In recent years, more and more international customers have found us through the nameplates on our products. They first use equipment with our drive axles, and then, convinced of their reliability, they seek direct cooperation. This not only confirms the quality of our products but also demonstrates the growing influence of the "Made in China" brand in the global market.

To better serve international customers, we have created a multilingual official website and technical documentation, formed a professional international sales team, and opened service centers in key regions. In addition, we have developed localized product series taking into account the conditions of different countries. These measures have significantly increased our competitiveness in the global market.

Future Outlook: Deepening Collaboration to Create Value

This visit of Belarusian clients opened a new chapter in our partnership. In addition to deepening cooperation in the field of drive axles for graders and loader axles, the parties agreed to cooperate on axles for wheeled excavators. The client plans to conduct trial tests of new products in the next quarter and, if the results are positive, begin serial purchases.

In addition, the parties discussed opportunities for cooperation in other areas. The customer showed great interest in our drive axles for electric construction equipment and expressed a desire to work on this innovative product. The issues of creating a regional service center and staff training were also discussed - these measures will improve the quality of service and create additional value for the client.

The successful visit of the Belarusian delegation not only strengthened existing cooperation and opened new directions, but also demonstrated the level of Chinese drive axle manufacturers. By continuing to follow the principles of "innovation, quality, service", our company will offer even better products and services to global customers, strengthening the position of "Made in China" on the global stage.

In the face of new challenges in the global construction equipment market, our company continues to deepen its internationalization strategy. Over the next three years, we plan to increase investment in R&D, focusing on breakthrough technologies such as smart and electric drive axles. At the same time, we are accelerating the construction of digital factories, introducing intelligent manufacturing systems to improve efficiency and quality consistency.