The drive axle of the excavator-loader undergoes rigorous bench testing

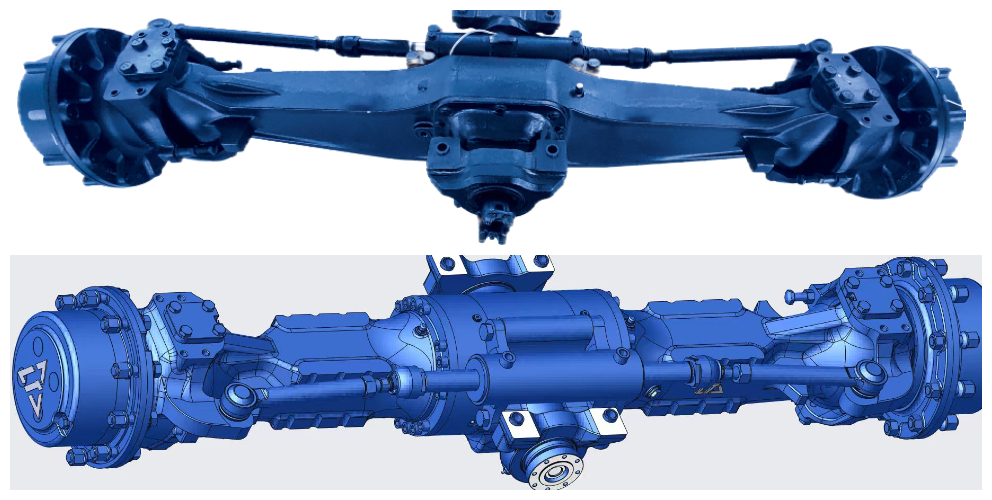

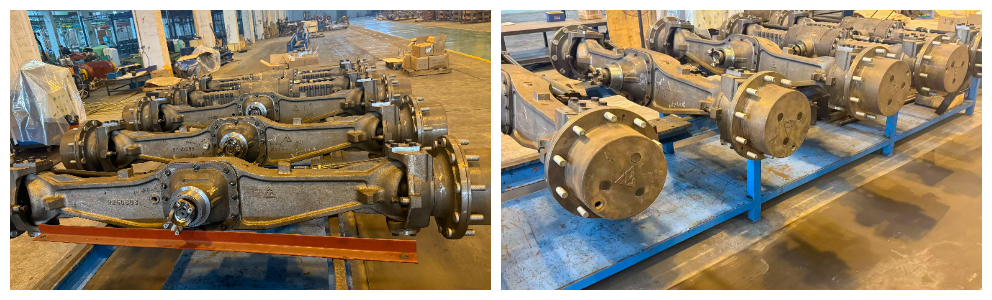

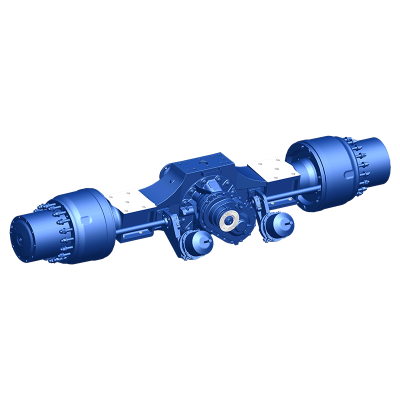

Our recently developed series of drive axles for backhoe loaders have successfully entered the system bench testing stage, marking a significant breakthrough for the company in the field of high-quality drive axle technology. In this series of products, both the front and rear axles adopt a steering drive axle design, breaking the limitations of the traditional drive axle layout and providing backhoe loaders with unprecedented maneuverability and operating flexibility. As the construction industry strives for high efficiency and reliability, this innovative design will redefine the performance standard for high-end backhoe loaders.

The drive axle, as the “running core” of construction equipment, directly determines the operating capabilities and reliability of the entire machine. The series of steering drive axles, which have entered the testing phase, are a landmark product developed by the company based on many years of technological experience and taking into account the special operating conditions of backhoe loaders. Compared with traditional drive axles, this series of products shows significant improvements in structural design, transmission efficiency and adaptability, fully demonstrating the company's deep technological knowledge and innovation ability in the field of drive axles.

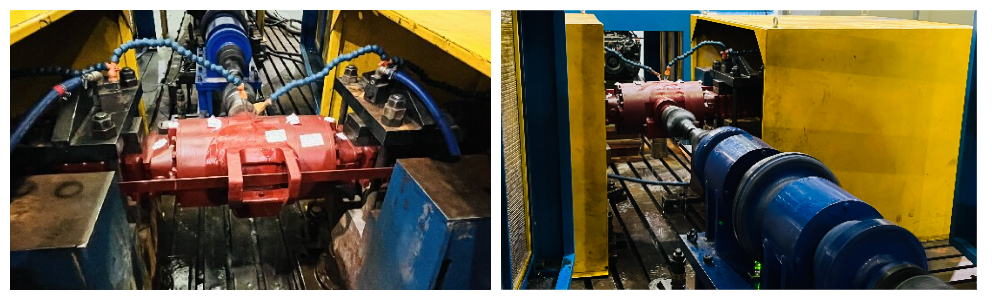

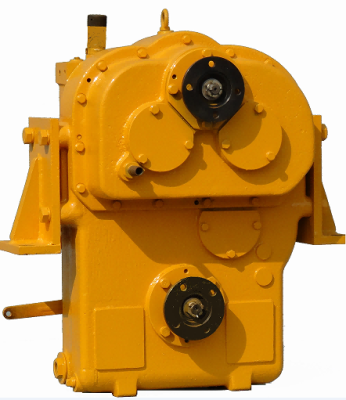

In these bench tests, special attention is paid to fatigue testing of the final drive gear teeth of the drive axle assembly. Gears, being key components of the drive axle transmission system, directly affect the service life and reliability of the entire axle. The tests will simulate long-term equipment operation under extreme conditions, testing the product's extreme performance under real-world operating conditions with testing intensity well above standard norms, ensuring full data support for the product's commercialization.

Superior Design: Innovative structure for superior performance

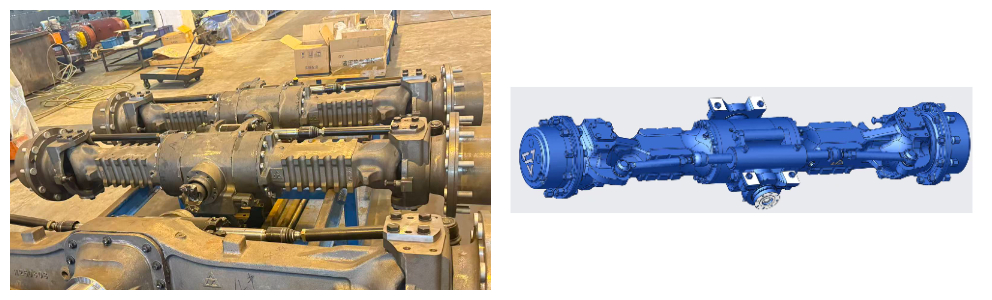

The innovative backhoe loader axle design is evident on several key levels. The layout with live axle steering on both the front and rear axles provides the vehicle with a tighter turning radius and increased maneuverability. On cramped construction sites or difficult terrain, this design significantly increases the maneuverability and efficiency of equipment. The front axle adopts a one-piece crankcase design, which provides stability under heavy load conditions with superior rigidity and load-bearing capacity. Precision casting techniques and optimized crankcase design achieve lightweight performance while maintaining strength, laying a strong foundation for improved performance across the entire machine.

The novelty of the rear axle lies in the use of a modular design concept. This design not only allows for more flexible adjustment of installation distance, but also allows for rapid adaptation, greatly improving product adaptability and production efficiency. The benefits of modular design also extend to ease of service: standardized interfaces and interchangeable components significantly reduce maintenance costs and downtime. For equipment users, this means higher availability and lower total cost of ownership.

The carefully thought-out design of the transmission is another striking feature of this product. Both front and rear axles use a two-stage gearbox design. Thanks to precise selection of gears and optimized gear ratios, maximum power transmission efficiency is achieved. This design not only satisfies the individual gear ratio requirements of different manufacturers, but also provides ample possibilities for individual configuration. Whether it's tough conditions that require powerful traction, or standard conditions that focus on efficiency, the optimal gear ratio solution can always be found.

Safety and reliability: Advanced braking system ensures safe operation

The brake system of the backhoe loader axle uses a fully enclosed multi-disc hydraulic brake system, which represents the advanced level of braking technology in construction machinery. Compared with traditional dry brake systems, the hydraulic brake system has significant advantages such as large braking torque, smooth and reliable braking, and long service life. The fully enclosed design effectively prevents the entry of dirt, dust and other contaminants, ensuring stable performance of the braking system under severe operating conditions.

Under real operating conditions, the hydraulic braking system demonstrates excellent adaptability. Whether long-term continuous downhill driving or cyclic operation with frequent stops and starts, the system maintains stable braking performance, effectively preventing the phenomenon of thermal brake wear. Running brake discs in oil not only provides better cooling, but also significantly reduces the frequency of maintenance. Data shows that the brake system's service interval can be more than 3 times that of traditional systems, saving users significant maintenance costs and time.

Accurate testing: bench tests guarantee superior product quality

Key fatigue tests are currently being carried out on the final drive gear teeth of the drive axle assembly. Testing is carried out on world-leading test equipment that simulates a variety of extreme load conditions and verifies the durability and fatigue strength of gears through millions of test cycles. During the testing process, the engineering team will continuously monitor multiple metrics including gear wear, temperature changes, noise levels, etc. to ensure each part meets design standards.

Equipping with a self-locking differential and a differential with forced locking further enhances the equipment's maneuverability in difficult conditions. When the vehicle encounters low-traction terrain such as mud, snow, or ice, these devices automatically adjust the torque distribution between the wheels, ensuring efficient transfer of power to the wheels with sufficient traction, which greatly improves the vehicle's off-road capability. For backhoe loaders that often operate in harsh conditions, this feature is especially important.

The ability to customize the product is also one of its key advantages. Thanks to the modular design and flexible parameter settings, it is possible to quickly respond to the individual needs of different machine manufacturers. Whether it is special requirements for installation dimensions or specific needs for performance parameters, everything can be satisfied by adjusting the design solutions. This flexible product development strategy allows the company to better serve diverse market needs.

Market Outlook: Technological Innovation Drives Industry Development

With the continuous advancement of infrastructure construction and the development of construction machinery, the market demand for high-performance drive axles is constantly increasing. Market launch of this series Steering Drive Axle is in line with the current trend of industry needs. Its superior performance and reliable quality are expected to attract widespread interest in the backhoe loader industry.

From a global market perspective, the demand for axle backhoe loader products continues to increase. Especially in regions with rapidly developing infrastructure, the demand for drive axles with advanced technology and reliable performance is especially urgent. The innovative product introduced by the company not only satisfies current market needs, but also sets a new benchmark for the technological development of the industry.

In the future, the company will continue to focus on technological innovation, continuously increase investment in R&D and improve product series. Based on existing achievements, the development team has already begun planning the development directions of the next generation of products, intending to achieve new breakthroughs in areas such as intelligentization and weight reduction. Through continuous technological innovation and product optimization, the company strives to provide global customers with better and more reliable leading solutions.

Market Outlook: Technological Innovation Drives Industry Development

With the continuous advancement of infrastructure construction and the development of construction machinery, the market demand for high-performance drive axles is constantly increasing. Market launch of this series Steering Drive Axle is in line with the current trend of industry needs. Its superior performance and reliable quality are expected to attract widespread interest in the backhoe loader industry.

From a global market perspective, the demand for axle backhoe loader products continues to increase. Especially in regions with rapidly developing infrastructure, the demand for drive axles with advanced technology and reliable performance is especially urgent. The innovative product introduced by the company not only satisfies current market needs, but also sets a new benchmark for the technological development of the industry.

In the future, the company will continue to focus on technological innovation, continuously increase investment in R&D and improve product series. Based on existing achievements, the development team has already begun planning the development directions of the next generation of products, intending to achieve new breakthroughs in areas such as intelligentization and weight reduction. Through continuous technological innovation and product optimization, the company strives to provide global customers with better and more reliable leading solutions.

Quality Promise: Careful manufacturing ensures superior performance

In the area of production technology, the company has invested significant resources to ensure product quality. From the procurement of raw materials to the release of finished products, strict quality control standards are established at every stage. State-of-the-art manufacturing equipment and technology coupled with an experienced manufacturing team ensures product consistency and reliability.

The quality control system also reflects the company's focus on product quality. In addition to standard dimensional inspection and performance testing, the company has deployed advanced flaw detection equipment and three-dimensional measuring machines to comprehensively inspect key components. This strict quality management system ensures that every drive axle produced meets the highest quality standards.

The creation of an after-sales service system also does not go unnoticed. The company has created a comprehensive system of technical support for customers, providing a full range of services from assistance in choosing a model, installation and setup to maintenance. With a remote diagnostic system, engineers can monitor equipment status in real time, identify potential problems early, and provide customers with accurate technical support.