Shandong Lutong: The leader in the overseas drive axle market

Recently, the foreign trade team of Shandong Lutong Heavy Industry Machinery Co., Ltd. presented technical solutions for core drive axle components at two major industry exhibitions in Wuhan and Shanghai to conduct in-depth research and establish contacts with customers. This trip not only promoted the expansion of cooperation with the three largest equipment manufacturers - Amkodor, PTZ and Rostov in Russia, but also took advantage of the dual advantages of "full-cycle foreign trade service + full-size production" to demonstrate the competitiveness of Chinese drive axle manufacturers abroad and press "Accelerator button" to expand the global market.

Foreign trade activities: A full range of turnkey services to create a standard of international cooperation

As a leading Chinese axle export enterprise, Shandong Lutong has established a full-cycle foreign trade service system covering the stages of "need coordination - customized solution - logistics and supply - service support", becoming a "reliable partner" for overseas customers.

Professional team and precise interaction:Employees of the foreign trade department have more than 5 years of experience in the field of international trade in special equipment, which allows them to provide “a response to a client’s request within 2 hours and preparation of an individual solution within 3 days.” To eliminate difficulties in technical communications with foreign customers, the team introduced an innovative service: “bilingual technical manual + individual online consultations”, guaranteeing smooth installation and commissioning of construction equipment drive axles and loader axles. Customer Review: “Shandong Lutong's service gives you a sense of local professionalism.”

Flexibility and efficiency in adapting to needs:To meet the diverse requirements of foreign customers, the team, together with the R&D department, has created a “rapid response mechanism for foreign trade orders” - standard drive axle models can be customized in paint color and packaging specifications, and the launch of production of customized loader axles (for example, changing the gear ratio for loaders of a certain tonnage) takes only 7 days from the moment the decision is confirmed.

Reliable provision of international supplies:Long-term cooperation has been established with several logistics companies, routes have been optimized taking into account the peculiarities of transportation to Russia. Standard drive axles are supplied according to the combined “sea + land” scheme with a stable delivery time of 35-40 days; For urgent orders of spare parts, a “special logistics direction” has been opened, allowing critical components (such as seals, bearings for drive axles of construction equipment) to be delivered to the customer’s enterprise in 7-10 days. In addition, the warehouse has created a “special area for foreign trade spare parts”, where more than 2,000 sets of frequently requested loader axle components are stored, allowing for a quick response to customer requests. The level of timely execution of foreign trade orders reaches 99%.

Vivid results of foreign trade activities:In 2024, drive axle exports exceeded 120 million yuan, representing a 45% increase year-on-year. The Russian market share reached 60%, and repeat purchases from key customers such as Amkodor and PTZ exceeded 80%. Drive axle exports for construction equipment consistently rank among the top five Chinese companies in the industry.

The company's strengths: the trinity of research and development + production + quality control, which creates a solid foundation for product manufacturing

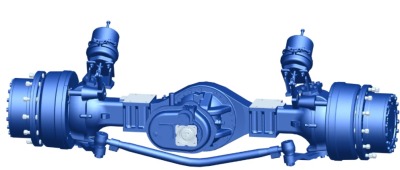

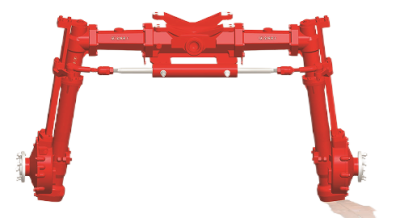

Shandong Lutong's continuous breakthrough in foreign trade is based on its comprehensive and reliable production strength in the field of drive axles, providing overseas markets with products with "high quality, high compatibility and high reliability".

Research and development strength leads the industry:The key development team has many years (10+ years) of experience in designing drive axles for special equipment and uses advanced international tools, such as 3D design in SolidWorks and dynamic modeling in ADAMS. In just 3 months, engineers optimized the drive axle design for extremely low temperature conditions in Russia, upgrading the frost-resistant lubricant and improving the design of the seals. Products supplied to Amkodor have a zero incident rate.

Leadership in Smart Manufacturing:An intelligent production base has been built with several specialized drive axle assembly lines that meet the highest industry standards. KUKA robotic welding lines (Germany) ensure welding accuracy of bridge housings ≤0.1 mm, 5-axis machining centers have increased the processing efficiency of key components by 50%. The daily production volume of standard drive axles reaches 300 units, the annual production volume is 50,000 sets. The timeliness of fulfilling foreign trade orders is 100%, the production cycle of individual orders is controlled within 35 days, which is 20% faster than the industry average.

Strict quality control standards:A “12-stage quality control system” has been introduced and high-precision instruments are used, including coordinate measuring machines and 3D scanners. Incoming raw materials undergo double testing for mechanical properties and chemical composition, 100% of key components are checked for compliance with geometric dimensions. Finished drive axles undergo 500-hour heavy load testing and leak testing. For construction equipment bridges exported to Russia, additional tests are carried out for starting at -40°C and for resistance to salt fog. The level of compliance of foreign trade products is 100%, there are no complaints about quality.

INexhibition interaction: Resonance of service and opportunities for deepening Russian-Chinese cooperation

During the exhibitions in Wuhan and Shanghai, Shandong Lutong, using a "dual-drive" approach (service + demonstration), reached a number of important agreements with Russian partners:

Preliminary agreements on annual purchase volumes were reached, individual supply chains were developed, priority production and exclusive warehouse storage were offered to ensure the continuity of the client's production processes.

In response to specific customer technical requirements, dedicated teams were quickly formed to collaborate with technical experts to conduct in-depth analyses, optimize the design and technology, and commit to completing prototype development within the specified timeframe.

Regular communication mechanisms have been established with customers to ensure constant updates on production and logistics status. Spare parts inventories are pre-built to accommodate customer fleet renewal plans, significantly improving response times in unforeseen situations.

Customer feedback: "Shandong Lutong products are reliable, and their service team responds quickly to our needs. This efficient and flexible cooperation model gives us confidence."

Planning for the Future: Expand the scope of foreign trade and strive to become a world leader

Based on the results of cooperation at the exhibition, Shandong Lutong formulated a foreign trade development plan for 2025: first, expand the foreign trade team, add language technical support specialists, and strengthen technical communication capabilities with customers; secondly, optimize the location of internal spare parts warehouses and divide foreign trade. supply of spare parts to warehouses and reduction of storage periods for shipment; third, strengthen cooperation with local Russian logistics service providers, optimize transportation routes and strive to reduce the usual drive axle transportation cycle to 30-35 days; Fourth, regularly publish driving axle application examples and product testing videos on the platform to improve the efficiency of brand recognition in the international market. Shandong Lutong has always adhered to the concept of “foreign trade service tree brand whose strength and quality wins the market.” In the future, the company will continue to deepen drive axle technological innovation and foreign trade service upgrading, build the world's leading drive axle foreign trade enterprise, and give strong impetus to China's intelligent manufacturing for the world.