What are the symptoms of a damaged drive axle?

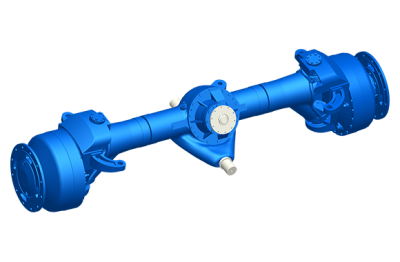

In the operation of construction, agricultural and mining equipment, the drive axle, as a key power transmission component, directly affects the efficiency and safety of the equipment. If the drive axle is damaged, this can lead not only to equipment downtime, but also cause an emergency. Shandong Lutong, as an enterprise specializing in the design and production of drive axles, draws on many years of industry experience to thoroughly analyze the typical symptoms of drive axle damage and reveal the secrets of producing quality drive axles for construction machinery.

I. Extraneous noise: "Early alarm" of drive axle malfunction

Extraneous noise is the most easily detected signal of drive axle damage. Noise in different situations often corresponds to different types of faults. When operating equipment such as loaders and excavators, if a “humming” sound appears when moving in gear, which weakens or disappears when coasting, this is often due to excessive clearance of the gears of the final drive of the loader axles. If you hear a knocking sound when turning, it may be caused by improper engagement of the differential gears and side gears.

To solve this key problem, Shandong Luton has formed a technical team of more than 20 experienced engineers specialized in optimizing the drive axle gear of construction equipment. By accurately calculating gear mesh parameters and using high-precision grinding equipment to machine bevel and spur gears, the loader drive axle gear mesh clearance is optimally within the range of 0.15-0.30mm, reducing the incidence of noise-related faults at the source.

II.Overheating: the “invisible killer” of core components

After the equipment has driven for a certain period of time, when you touch the drive axle body with your hand, a feeling of abnormal heat occurs. This is a typical manifestation of overheating failure. Such problems are mainly caused by overuse of the bearing assembly, wear of the transmission oil, or too little clearance in the mesh. Prolonged overheating accelerates the wear of gears and bearings and shortens the life of the drive axle. In severe operating conditions such as mining equipment, the problem of overheating becomes more severe and higher demands are placed on the heat resistance of the drive axle.

Shandong Lutong introduced bearing preload adjustment equipment imported from Germany, which can accurately control the strength of the bearing assembly through an automated system, thereby avoiding the problem of too much preload or looseness. At the same time, the company has established strict oil testing standards, filled each drive axle of construction equipment with suitable long-lasting gear oil, and carried out a thermal run-in without load for 2 hours before leaving the factory to ensure proper lubrication of gears and bearings. Considering the high performance of the backhoe loader drive axle, the heat sink design is further optimized to improve heat dissipation efficiency by 30%.

III. Oil leakage: “Safety hazard” during equipment operation

The presence of obvious traces of oil on the oil filler neck, oil seals or drive axle mating surfaces indicates a leak. A clogged breather, aging seals, or casting defects in the axle housing can cause oil leakage, and transmission oil leakage will directly impair the lubrication of internal components and cause chain damage. For agricultural machinery operating in the field, oil leakage can also pollute the environment.

To completely solve the problem of oil leakage, Shandong Lutong uses end seals and high-strength sealing gaskets, combined with 3D scanning technology to check the flatness of the axle housing mating surfaces, ensuring the seal seal sealing rate is up to 99.8%. The company's drive axle assembly shop is equipped with 12 CNC machining centers and 3D measurement equipment to conduct full-scale inspection of cast axle housings. Before shipment, each forklift drive axle undergoes a 48-hour static pressure test to check for leaks, and only after it is confirmed that there are no leaks, the product is sent to the warehouse.

Choosing the right drive axle to prevent the risk of failure at source

Recognizing the symptoms of drive axle failure is key to equipment maintenance, and selecting a quality drive axle is the foundation for reducing the likelihood of failure. Shandong Lutong has been in the field of drive axles for more than ten years, has a modern production base of 120,000 m², an annual production capacity of 30,000 units, and products cover fields such as construction, agricultural and mining machinery. The company has established a comprehensive quality control system of "raw material inspection - production monitoring - finished product testing", and all construction machinery drive axles are certified by ISO9001 quality system.

The company has created a comprehensive quality control system “raw materials - production - finished products”:

Raw material stage: Each batch of steel and bearings undergoes mechanical testing, and substandard raw materials are rejected directly.

Production stage: Implement a production management system to control the processing accuracy of each technological process in real time to ensure product uniformity.

Finished Product Stage: All drive axles must pass three key tests: leak tightness, idle running, and under load, and only after being deemed suitable are they marked and sent to the warehouse.

Whether it's forklift drive axles designed to cope with harsh environments or universal drive axles for multi-tasking scenarios, Shandong Lutong can provide customized solutions. From the design of the technical solution to the shipment of products, a professional team accompanies the entire process, ensuring that each product meets the requirements of the equipment. Choose Shandong Lutong drive axles to keep your equipment free from malfunction problems and improve operating efficiency.