Behind a new breakthrough in drive axle technology: the release of a new model of a wheel gearbox

Technical innovation: Wheel drive gives powerful impetus to platforms for working at height

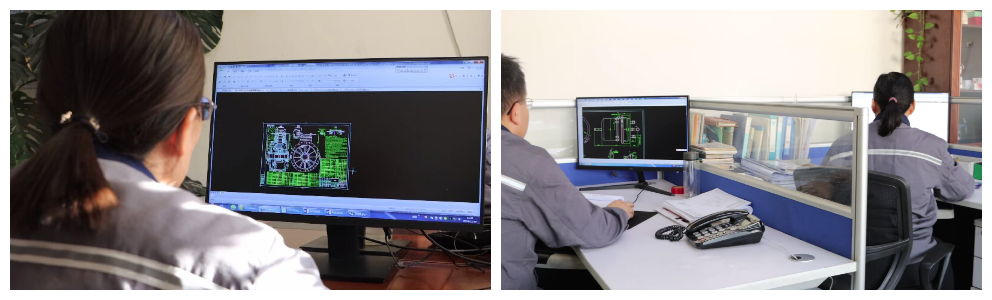

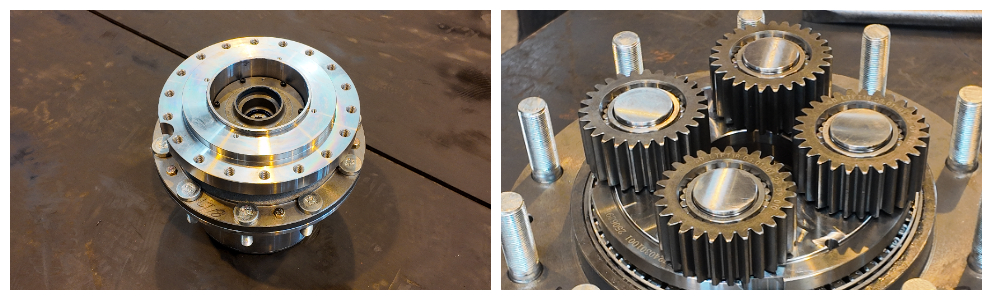

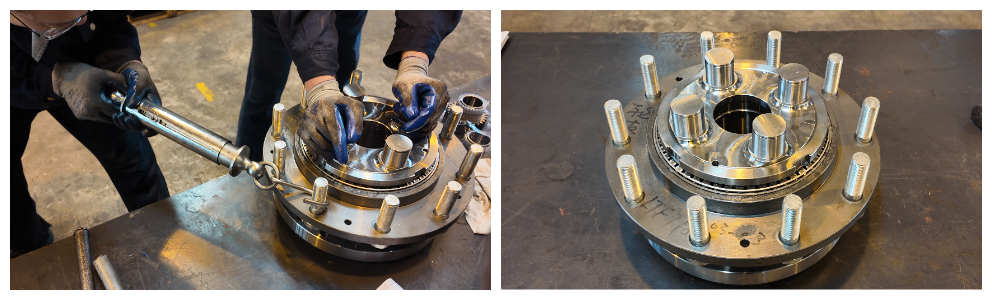

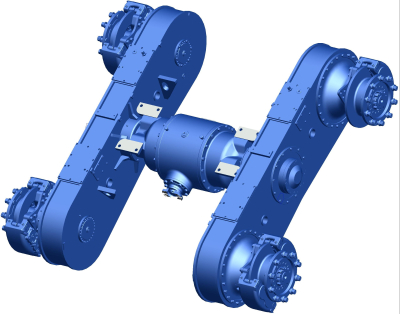

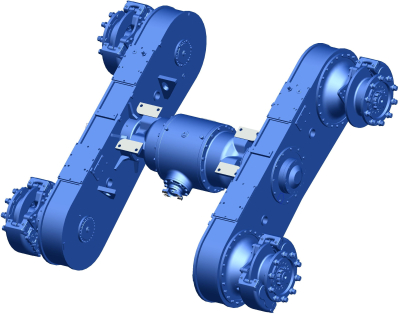

Recently, a significant technological breakthrough occurred at the Shandong Lutong Research Center - a new wheel gearbox specially designed for platforms for working at height has completed the first batch of assembly and has officially entered the testing phase. As a Chinese manufacturer's drive axle, this wheel reducer from Shandong Lutong adopts the advanced modular design concept, achieving the international advanced level in terms of transmission efficiency, compact structure and low noise operation.

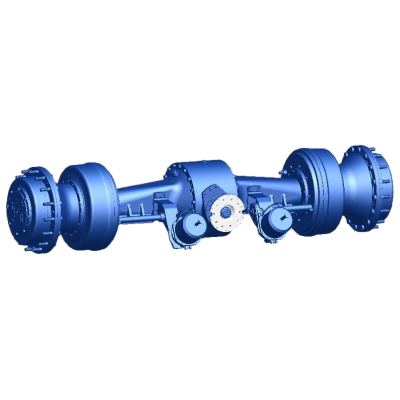

This wheel reducer uses advanced gear design concepts to significantly improve transmission efficiency by optimizing the transmission path and gear parameters. Traditional drive axle systems often have disadvantages such as complex design, low transmission efficiency and inconvenient maintenance. The Shandong Lutong development team, after in-depth market research and technical feasibility, decided to start with key drivetrain components by developing a wheel reducer specifically designed for work-at-height platforms. Compared to traditional drive axle solutions, wheel drive has the advantage of being able to directly transfer power to each wheel, effectively reducing energy loss in the drive chain.

As the technical representative of a Chinese manufacturer's drive axle, Shandong Lutong fully considered the special operating needs of platforms for working at height during the product design stage. Considering the extremely high stability requirements when working at height, the wheel reducer adopts a special anti-vibration design to ensure platform stability during lifting operations. This innovative drive method allows each wheel to independently receive optimal traction, significantly increasing the equipment's maneuverability in difficult road conditions.

In-Depth Research: The Path of Technology Innovation Driven by Market Demand

The development process of this wheel reducer has absorbed the wisdom and tenacity of Shandong Lutong's technical team. As a drive axle manufacturer, at the beginning of the project, the development team conducted in-depth research into the domestic and international market for work-at-height platforms. They found that with the acceleration of urbanization and increasing construction requirements, platforms for working at height are evolving towards greater height, stability and intelligence. While traditional drive axle systems gradually revealed their limitations in meeting these new needs.

During the development cycle, the Shandong Lutong team overcame many technical challenges. The most difficult of these was the task of achieving a high gear ratio in a limited space. By using a new combination drive design combining multi-stage planetary gear and parallel axis, the development team was able to achieve the required gear ratio in a compact package. This innovative transmission structure not only satisfied the performance requirements, but also reduced the weight of the entire gearbox by approximately 15% compared to traditional drive axle solutions.

A breakthrough in materials science was also a key factor in the project's success. The main gear parts of the wheel reducer are made of high quality alloy steel, processed by carburizing, hardening and precision grinding, ensuring the product's durability under heavy load conditions. The body part is made of high-strength aluminum alloy, which achieves weight reduction goals while maintaining structural strength. The selection of these materials and the application of technology have enabled Shandong Lutong to find the optimal balance between performance and cost.

Superior Performance: Multiple innovative technologies create an industry benchmark product

This wheel reducer has many striking features in terms of performance. First, a breakthrough in transmission efficiency: by optimizing tooth modification technology and using low-viscosity, high-performance lubricants, power losses during the transmission process were minimized. In real-world testing, this product ran 15-20°C cooler in rated operation than its drive axle counterparts, meaning not only higher energy efficiency, but also a predicted longer service life.

In terms of load capacity, the new product demonstrated outstanding performance. Through the use of multi-gear load balancing technology and advanced bearing arrangement, the torque of the wheel reducer has increased by more than 20% compared with traditional drive axle products of the same size. This breakthrough allows work-at-height platforms to adapt to harsher work environments and meet the demands of heavy-duty work. Most notably, the product maintains high lifting capacity while keeping noise levels below 70 decibels, creating a more comfortable work environment for operators.

Sealing is another notable feature of the wheel reducer. Shandong Lutong's design team, taking into account the difficult operating conditions that work at height platforms often encounter, such as dust, dirt, etc., has developed a multi-layer intrusion protection system. The main seal uses high-performance sponge O-rings, combined with a unique labyrinth dust-proof design, effectively preventing the penetration of external contaminants. Testing has shown that this sealing system performs excellently in durability tests that simulate harsh conditions, providing reliable sealing throughout the life of the product.

Market prospects: Technological innovation as a driving force for industry development

With the continuous development of global urbanization, the demand in the high-altitude operating platform market continues to grow. According to industry reports, the global high-platform device market's CAGR is expected to remain above 7% over the next five years. In this context, efficient and reliable operating systems are becoming a focus for hardware manufacturers. As a Chinese drive axle manufacturer, Shandong Lutong provides timely wheel drive solutions to meet the market demand for high-performance drive systems.

In terms of technological development trends, high-altitude work platforms are rapidly developing towards electrification and intelligentization. The wheel reducer developed by Shandong Lutong has been designed to be compatible with the electric drive system from the very beginning; Its efficient transmission characteristics allow the electric platform to significantly increase its range. At the same time, the intelligent interface provided in the product provides capabilities for remote monitoring, troubleshooting and other functions.

In terms of technological development trends, platforms for working at height are rapidly evolving towards electrification and intelligentization. The wheel reducer developed by Shandong Lutong has been designed to be compatible with electric drive systems from the very beginning; its efficient transmission characteristics can significantly improve the range of electric platforms. At the same time, the intelligent interfaces provided in the product provide opportunities for implementing functions such as remote monitoring, fault diagnosis, etc.

In the field of after-sales service, Shandong Lutong has established a rapid response mechanism, providing technical support services 24 hours a day. In addition, spare parts centers have been established in the country's major regional markets to ensure timely supplies. For the international market, the company plans to establish overseas warehouses in key regions to provide localized service support to international customers.

Strategic importance: improving product range and comprehensively increasing competitiveness.

The successful development of the wheel side reducer is of great strategic importance for the long-term development of the company. First of all, it has enriched the company's product range and enabled it to form a more complete product system in the field of walking systems for construction machinery. The company can now offer customers with different needs a variety of walking solutions - from the traditional drive axle to the new type of wheel reducer. This variety of products not only improves competitiveness in the market, but also increases risk tolerance.

Secondly, the technical experience accumulated in the development process of this product will serve as a valuable reference for the innovation of the company's other products. In particular, the achievements in the development of compact transmission devices and efficient data transmission technologies can be popularized and applied to other product series. The R&D director said: “Through this project, we have established a complete micro transmission system development process, and the value of this methodology even exceeds the value of the product itself.”

More importantly, the successful development of the wheel reducer demonstrates the company's ability for technological innovation. In this segment, which has high technical demands, breakthroughs have been achieved, proving that the company is able to compete in the high-end market. This will help strengthen the company's brand image and lay the foundation for attracting more high-end customers. At the same time, it is also the best interpretation of the company's development strategy of "technological enterprise".