Shandong Lutong drive axle is exported in large quantities, which doubles the quality and durability.

With the acceleration of agricultural modernization, infrastructure construction, and energy resource development, the construction, agricultural, and mining equipment markets are placing ever-higher demands on the reliability and compatibility of key components.Shandong Lutong, as a leading domestic drive axle manufacturer, has more than 30 years of industry experience, focusing on the research and production of key components for equipment in various fields.Recently, a batch of high-performance drive axles for tractors and graders was successfully shipped to Russia, including specialized drive axles for 400 hp tractors.PTZ, as well as customized products for graders of the UMGA and Amkodor brands.At the same time, the latest development was officially launched on the market – Tandem axles for logging machines.With a broad product portfolio for all application scenarios and strict quality standards, the company has become a reliable supplier of drive axles on the Russian market.

Technical foundation: advanced team and modern equipment as the basis for core competencies

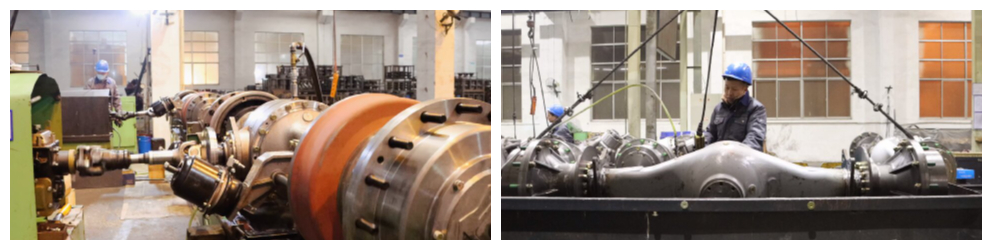

Shandong Lutong always regards technological development and production capacity as the basis of its development, creating a closed-loop system of full cycle "research - production - testing". The company employs more than 300 employees, of which more than 20% are R&D employees. Key technical experts have over 15 years of development experience in the drive axle industry and cover various professional fields including mechanical engineering, materials science, performance testing, and have obtained many national utility model patents.

Production workshops occupy an area of more than 120,000 square meters. m. and are equipped with world-class advanced manufacturing and inspection equipment, including CNC machining centers from Germany, precision grinding machines from Japan, laser measuring instruments, three-coordinate measuring machines, etc., allowing the complete in-house processing of key drive axle components such as housing and gears. Through the implementation of an intelligent production management system, real-time production process monitoring and data traceability are achieved, the processing accuracy of key drive axle dimensions is controlled within ±0.005mm, and the annual production capacity exceeds 50,000 sets, which can meet the supply needs of large quantities of orders around the world. In addition, the company has established an industry-leading drive axle performance testing laboratory capable of simulating extreme operating conditions and providing comprehensive data support for product development and quality control.

Quality as the soul: strict control at all stages strengthens export confidence

Shandong Lutong aims for zero defects and has established a lifecycle quality management system that significantly exceeds industry standards. Every operation, from raw material procurement to finished product manufacturing, undergoes a rigorous, multi-layered inspection process, ensuring that every drive axle boasts superior reliability and durability.

At the stage of purchasing raw materials, strategic direct cooperation has been established with leading domestic metallurgical enterprises. All key materials undergo double testing: material composition testing and mechanical properties testing to nip quality risks in the bud. There are 12 key control points throughout the manufacturing process, including component accuracy testing, weld strength testing, assembly clearance calibration, etc. Before shipment, each drive axle must undergo continuous 72-hour load testing, 100,000 cycles of impact fatigue testing, and high and low temperature cycling tests to ensure that the key benefits of stable power delivery and low failure rates are maintained, even under extreme conditions.

Currently, the company's products are certified according to the standards of the ISO9001 quality management system and ISO14001 environmental management system. At the same time, customer satisfaction in the Russian market for tractor drive axles and grader drive axles remains above 98% for three years in a row. Due to their notable advantages - "frost resistance, wear resistance, high load capacity, long service life" - they have become the preferred brand for local agricultural cooperatives and construction enterprises.

Product matrix: precisely matching the needs of different scenarios

Based on strong R&D and manufacturing capabilities, Shandong Lutong has created a complete series of drive axle products for construction, agricultural and mining machinery, precisely meeting the requirements of various types of machines.

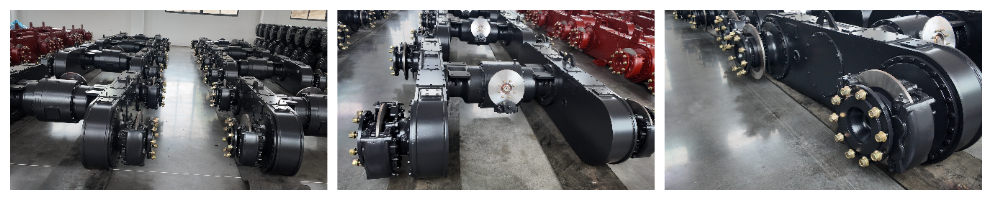

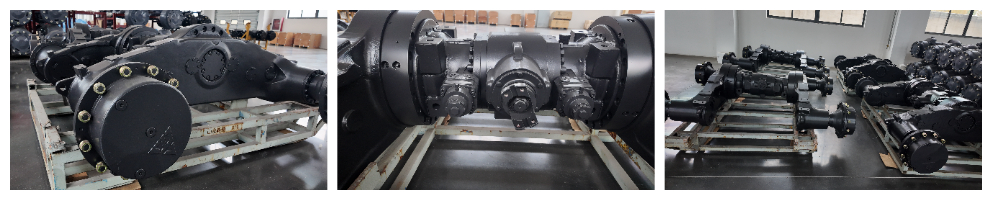

A batch of tractor drive axles for the Russian PTZ model with a power of 400 hp, exported to Russia, was specially designed for intensive agricultural work on vast Russian fields. It uses reinforced body structure and high-precision bevel gears, the maximum input torque reaches 9500Nm, the load capacity is 25% higher than similar products in the industry, which can easily adapt to various agricultural operations such as deep plowing, sowing, harvesting, effectively improving the productivity and fuel efficiency of the tractor. Grader drive axles for UMGA and Amkodor brand graders are gear ratio optimized for engineering scenarios such as road construction and site grading, with gear efficiency reaching 96%. The wheel's floating mechanical seal design and wear-resistant coating technology are simultaneously adopted to provide superior dust and water protection performance and adapt to the challenging working conditions of Russian construction projects.

The latest development - Tandem axles for forestry machines - is focused on the needs of the forestry industry. It innovatively uses low-temperature materials and shock-resistant design to maintain good lubrication and transmission performance even in low-temperature environments, solving an industry problem with traditional drive axles - seal sticking and failure in harsh climates. In addition, the company has developed heavy-duty drive axles for mining equipment and lightweight drive axles for small agricultural equipment, forming a multi-dimensional, all-scenario product line to meet the individual needs of various customers.

Service support: efficient operation and localization support to gain trust

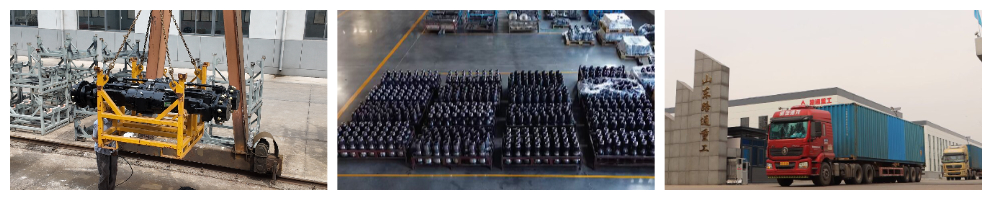

In addition to superior product quality, Shandong Lutong's perfect supply chain and service system have also become an important guarantee for export business. The company has established an efficient service mechanism for the entire process of "order response - production - quality inspection and delivery - after-sales support", and specially formed a bilingual service team and logistics support team for the international market. The response time to orders does not exceed 24 hours, and the quality of service; the production cycle for wholesale orders is 30% shorter than the industry standard.

The delivery process uses the “customized packaging + strategic joint logistics” model. According to the characteristics of precision drive axle components, multi-layer packaging materials are used, which are moisture-resistant, frost-resistant and earthquake-resistant, with built-in shock-absorbing devices and anti-corrosion properties. treatment to prevent damage to the product during long-distance transportation. The company has established long-term cooperation with large logistics companies such as Sinotrans and COSCO Shipping, opened specialized transport channels and realized door-to-door direct service from factory to customer's warehouse with a stable delivery cycle of 15-20 days. At the same time, the company has established an after-sales service center equipped with professional maintenance engineers and sufficient stock of spare parts, which can meet customers' service needs within 48 hours and provide a full range of product stability guarantees.

In the future, Shandong Lutong will continue to focus on the core areas of drive axle production, continue to increase investment in research and development, optimize productivity and product quality according to changes in demand in the Russian and global markets, expand the range of mining machinery drive axles, intelligent agricultural machinery drive axles and other fields, deepen cooperation with world-famous equipment manufacturers, and create the world's leading brand of drive axles with higher technical specifications, stricter quality standards and more advanced service system, to become the main driving force in the modernization of the global engineering industry.