Batch shipment shows strength: A series of grader drive axles sets sail around the world

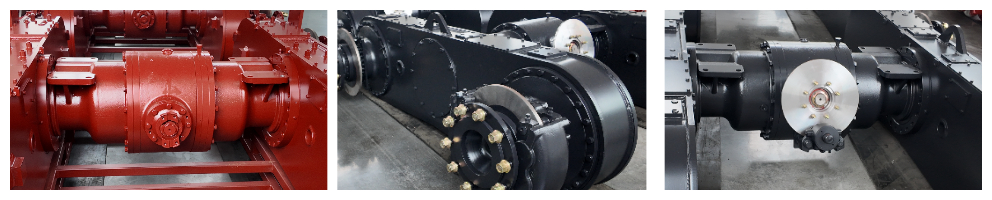

Recently, batches of carefully crafted grader drive axles are being carefully loaded in our company's shipping area and will soon be shipped to major OEMs and end users both at home and abroad. Covering a complete series of 160-220 HP, these products include not only time-tested standard models, but also high-end models specially designed for extreme cold conditions, demonstrating our company's deep technical expertise and strong manufacturing capabilities in the field of grader drive axles. Previously, several dozen drive axles for high-power graders 260-270 hp. have already traveled to Belarus, where they are being tested in harsh conditions at large local mines.

At the shipping site, workers carry out final checks in a calm and orderly manner. Each drive axle must undergo rigorous factory testing to ensure full performance parameters are met. The technical manager, pointing to the products ready for shipment, explained: “This grader drive axle model being shipped to Russia was developed by us taking into account the special needs of the local market. It uses a reinforced design and special frost-resistant materials, which allows it to operate stably in extremely cold conditions at temperatures down to minus 40 degrees. Initial feedback from trial use has been very positive, with customers praising the product's performance in harsh conditions.”

Standard models of drive axles with a power of 160-200 hp. and 200-220 hp. mainly supplied to well-known domestic OEMs such as LiuGong, and will also be exported to countries such as Russia and Belarus to supply well-known international manufacturers such as UMG and Amkodor. These products, which have undergone extensive market testing, have won wide acceptance from customers around the world for their outstanding reliability and cost-effectiveness.

Technical Leadership: Balance Box Design Provides Superior Performance

The key advantage of our company's grader drive axle series is its innovative balance box design. This design connects the middle and rear wheels through a cascaded drive structure, allowing the system to maintain the same rotation speed and torque distribution on both sides, effectively solving the problem of wheel slip that plagues traditional drive axles in challenging conditions. Engineering test data shows that this design can reduce tire wear by more than 30% while significantly improving chip smoothing accuracy.

“The design of the balance box is the key difference between our product and conventional drive axles,” emphasizes the technical director, talking about the features of the product. “It acts as a precise torque distributor, automatically adjusting the traction force on the wheels depending on the road surface conditions, thereby ensuring optimal traction characteristics of the equipment.” In practice, this feature allows graders with our drive axles to maintain stable performance on a variety of challenging terrain, be it road construction or quarry grading, delivering superior results.

It is worth noting that the entire series of these products is equipped with a self-locking differential as standard, which further increases the maneuverability of the equipment in difficult conditions. When one wheel begins to slip, the system automatically transfers torque to the wheel with good grip, ensuring sufficient traction is always available. This feature is especially important on difficult surfaces such as mud or loose soil, effectively preventing equipment from getting stuck.

It is worth noting that the entire series of these products is equipped with a self-locking differential as standard, which further increases the maneuverability of the equipment in difficult conditions. When one wheel begins to slip, the system automatically transfers torque to the wheel with good grip, ensuring sufficient traction is always available. This feature is especially important on difficult surfaces such as mud or loose soil, effectively preventing equipment from getting stuck.

In terms of structural strength, the drive axle adopts heavy engineering chain transmission, whose impact resistance and durability are far superior to conventional products. Experience has proven that this drive axle can withstand impact loads up to 150% higher than the rated axle, fully complying with the most stringent construction requirements. At the same time, the optimized lubrication system and seal design ensure long product life even in dusty, humid and other harsh conditions.

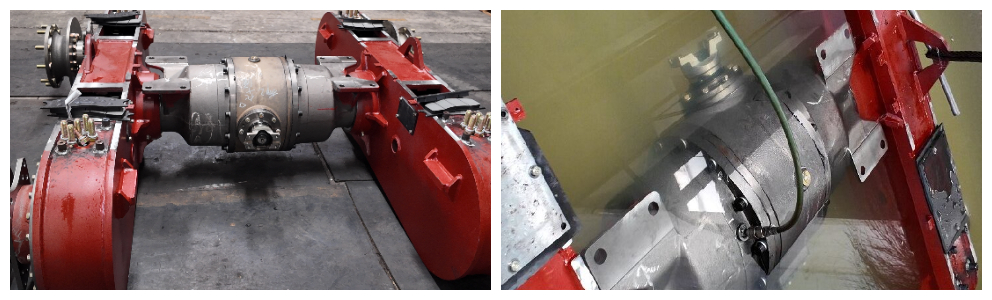

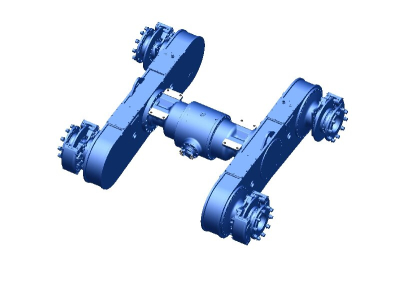

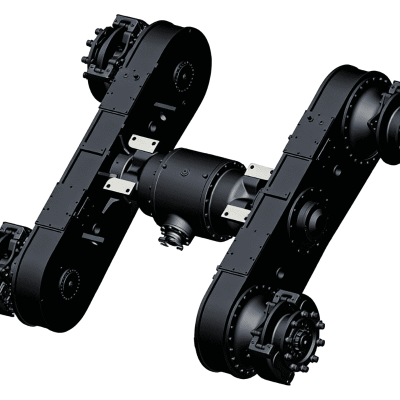

Customized solutions: three-axle drive axle for special conditions

In addition to the standard series with balance box, our company has also developed customized three-axle drive axle for special markets such as Russia. This innovative design ensures that the front, middle and rear axles are driven, thus realizing all-wheel drive. In field testing, this configuration increased equipment tractive effort by more than 40%, completely eliminating the slippage problem common with traditional graders when working on loose soils and steep slopes.

The front axle uses a classic portal design, with a carefully calculated offset between the centerline of the input shaft and the center of the wheel. This design, while providing turning characteristics, significantly increases the vehicle's ground clearance. Engineering test data shows that portal axle graders have a minimum ground clearance that is more than 25% higher than traditional designs, allowing the equipment to easily handle potholes, rubble and other challenging conditions while effectively avoiding the risk of chassis impacts.

The middle and rear axles use a unified platform design, with the input gear teeth cutting in the opposite direction. This design significantly increases parts commonality, allowing customers to reduce inventory and reduce maintenance costs. At the same time, thanks to the articulated suspension and flexible connection to the frame, the equipment better adapts to uneven surfaces, allowing more wheels to contact the ground at the same time, which improves both traction and smoothness.

One of the Russian customers, after trial use, noted: “This custom three-axle drive axle has completely changed our understanding of the cross-country ability of graders. In the muddy conditions of the spring thaw, traditional equipment often has difficulty moving, but a grader with a three-axle drive can move as if on level ground. More importantly, its platform design makes maintenance extremely easy, which is especially valuable when working in remote areas.”

Global verification: quality gains international recognition

Our company's series of grader drive axles have already been tested in many markets around the world. In China, through long-term cooperation with major manufacturers such as LiuGong, the products have been tested under various conditions. According to statistics, the mean time between failures of graders with our drive axles in road construction exceeds 3000 hours, which corresponds to the international advanced level.

On the international stage, the products also demonstrate outstanding results. Drive axles with a capacity of 260-270 hp, sent to Belarus, underwent severe tests in quarry conditions. Local users report that these products can start and operate normally even in extremely low temperatures as low as minus 40 degrees, and their reliability has completely surpassed similar international products. Especially under continuous operation with heavy loads, the main components of the drive axle showed good durability and their service life significantly exceeded expectations.

“We were impressed by the adaptability of the products,” noted a client from Belarus. — The annual temperature difference in Siberia exceeds 80 degrees, from +35 in summer to -45 in winter, which is a severe test for any mechanical equipment. But your company’s drive axles maintained stable performance throughout the entire temperature range, which is truly commendable.”

In the Russian market, the individual three-axle drive axle has received wide recognition. Several customers have reported that this locally tailored product actually solves problems encountered during the construction process. Its superior all-terrain capability and reliability have helped users significantly improve work efficiency and reduce operating costs. Based on previous successful experience, several Russian customers have recently placed additional orders.

Manufacturing Strength: Intelligent Manufacturing to Ensure Product Quality

Excellent product performance is inseparable from advanced manufacturing technology and strict quality control. In our intelligent production workshop, dozens of high-end CNC machines carry out precise processing of various drive axle parts. From the processing of main parts to the assembly of the unit, each link has been automated and is an intelligent production process.

The reference to quality testing cannot be ignored. The company has a well-established testing laboratory equipped with advanced equipment such as three-dimensional measuring machines and spectrum analyzers. Each batch of products must undergo strict inspection through more than 30 processes, such as material analysis, dimensional and performance testing. In particular, it is worth noting that the company has also installed an entire bridge test rig, which can simulate various operating conditions to carry out comprehensive testing of the drive axle performance.

To ensure product reliability, all new models must undergo rigorous strength testing before mass production. At the test site, the drive axle must undergo continuous full load testing, including extreme operating conditions such as shock loading and cyclic loading. Only those products that pass all these tests can ultimately be delivered to customers for use.

Service Guarantee: Global Layout Helps Customers Succeed

To better serve customers around the world, our company has established a perfect after-sales service system. In China, the company has established a number of regional service centers to provide 24-hour technical support. In the international market, through cooperation with local distributors, spare parts warehouses and technical service teams have been established in key markets such as Russia and Belarus.

“We promise to provide a solution within 4 hours of receiving a service request and complete the supply of spare parts within 48 hours,” said the after-sales service director. “This rapid response mechanism ensures high attendance at customer equipment.” According to statistics, the fulfillment rate of this service commitment has reached more than 98%, which has been highly appreciated by customers.

In addition to timely after-sales service, the company also provides professional technical training. Regularly conduct technical training courses for customers to explain the basic points of product use and maintenance, and share troubleshooting experience. Since this year, more than 200 equipment management and maintenance personnel have been trained for domestic and foreign customers, which has effectively improved customers' ability to solve problems themselves.

It is worth noting that the company has also established an ideal customer feedback mechanism. Collect the problems and suggestions that customers encounter during use through regular repeat visits, on-site research, etc. This first-hand information serves as an important reference for continuous product improvement, forming an optimal cycle of technology iterations. Please translate completely into Russian, do not change the format, the output article will retain the format of the Chinese version, will be published on the Yandex website. please change the drive axle to "Grader Drive Axle".