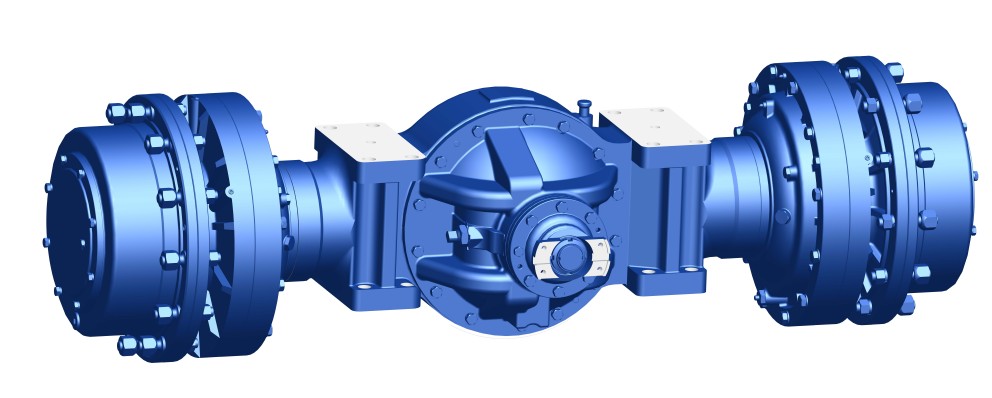

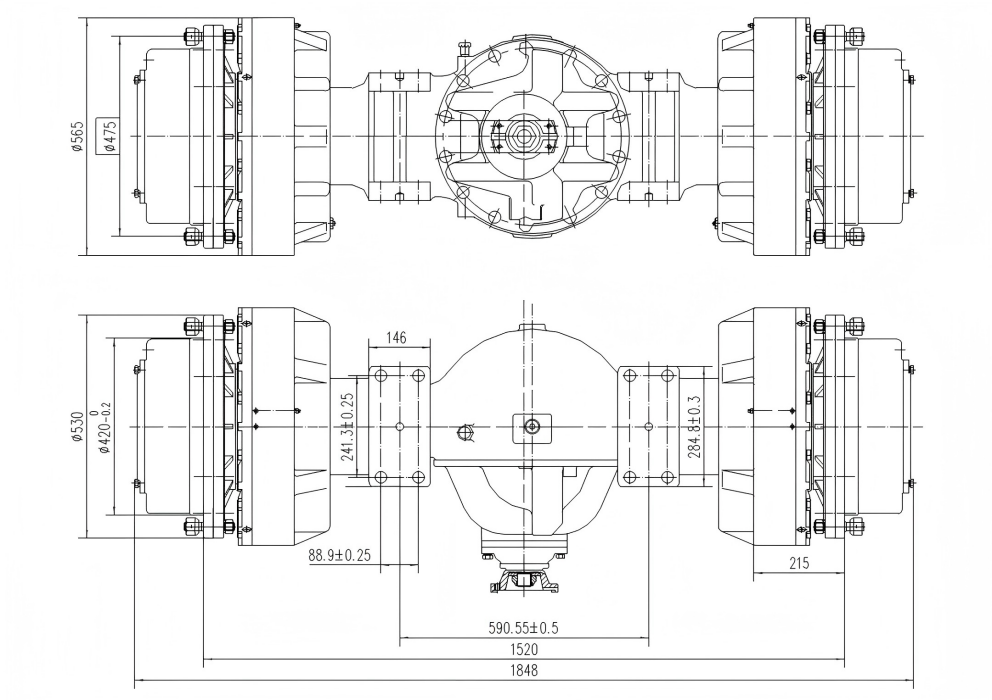

Drive axle of an underground loading and unloading machine 3 m³

1.Transmission, high efficiency and low noise

2.High load capacity and high adaptability.

3. Reliable and powerful braking

4. Flexible choice of functions

5.Compact and reasonable design

Main characteristics:

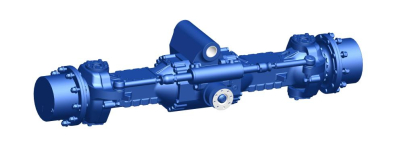

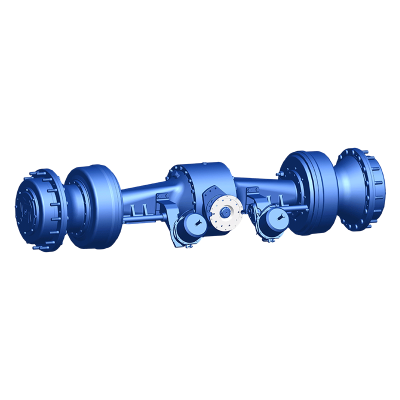

Being a leading enterprise in the field of production of leading bridges for construction equipment in China, the company Shandong Lutong Heavy Industry Machinery Co., Ltd., based on more than 30 years of technological experience, released a high-performance leading bridge, specially designed for underground scrapers of 3 cubic meters of 3 cubic meters. The axis of the underground scraper Shandong Lutong 3 Cubic is specially designed to work in difficult underground conditions, and the main parameters correspond to world -class models. The leading axis of an underground scraper of 3 cubic meters, designed to work in extreme conditions, is designed to take into account the concept of “safety, reliability and efficiency” in combination with special The needs of underground mines and ensures a breakthrough in key technologies such as drift protection, inhibition and sealing. Auxiliary product for domestic and foreign mining enterprises.

Given the operational characteristics of an underground scraper of 3 cubic meters, the leading bridge is made of a solid cast steel frame, the voltage distribution is optimized using a finite-element analysis, and the bending strength is increased by 30%. When using a two-stage transmission with a slowdown equipped with high-precision armpic gear and planetary wheels and planetary transmissions, transmission efficiency reaches 96%, and energy consumption decreases by 18%. The optical anti-slip differential of no-spin allows 100%to block the sliding of the wheels on the dirty road, and the clutch with the road increases by 40%. The technology provides an instant response due to mechanical limited slip, without the need to use electronic control modules, and adapts and adapts and adapts and adapts. To an underground environment with high dusting and strong electromagnetic interference. Open part has a floating stuffing oil seal, which effectively opposes groundwater erosion and sludge. All searches for keys are made of high -quality imported materials, such as Europe and the United States, which significantly increases their service life.

MAIN TECHNICAL PARAMETERS:

Overall overall gear ratio |

26.118 |

Maximum input torque |

5000N.m |

Load per bridge |

19050Kg |

Brake system oil pressure |

10Mpa |

Working volume of one-way brake |

164ml |

Moment of braking of one side |

20000N.m |

Drive axle oil requirements (API classification) |

GL-5: transmission oil 85W/90 (use at temperatures above -12°C) |

Brake fluid and brake coolant |

Hydraulic oil L-HL46 |

As a high -tech enterprise of the national level, Shandong Lutong received a total of 36 patents associated with leading bridges, and passed the certification of the ISO 9001 quality management system. The intellectual line of processing of the main gearbox is equipped with a five -axis hinged processing center, and the allowances of key size are regulated at the level ± 0.005 mm. The changing axis was tested for a 120% nominal load using a load test system to ensure a 100% factory level of cross-country ability.

Certification of the ISO 9001 quality management system

Automatic line for the production of differential buildings

Automatic line for the production of the planetary wheel frame

Being the main component of the transmission of the well scraper, the leading bridge directly affects the efficiency of work, operation safety and the service life of the equipment with its subsequent maintenance. The next technical maintenance guide was specially developed taking into account the design features of the leading bridge of the underground scraper Shandong Heavy Industry with a volume of 3 cubic meters and 3 cubic meters and difficult working conditions underground to provide users systematic decisions on maintenance.

1. Basic principles of maintenance:

Preventative maintenance: Through regular checks and maintenance, potential faults are identified early, avoiding unexpected downtime.

Level Maintenance: Strictly adhere to daily, weekly, monthly, quarterly and annual maintenance cycles to form a closed maintenance cycle.

Adaptation to the environment: Enhanced maintenance for special operating conditions with high dust, high humidity and strong vibration underground.

Data management: create maintenance files, record changes in key parameters and predict failure trends.

2. Diagnosis and troubleshooting of common faults:

| Fault phenomenon | Possible reason | Elimination method |

| Abnormal noise from the drive axle | 1. Insufficient amount of transmission oil or deterioration of oil quality A. Too much clearance in gear engagement 3. Slight bearing wear |

1. Add or replace transmission oil A. Adjust the gap between the teeth 3. Replacing worn bearings |

| Oil leak from wheel side | 1. Damage to the floating seal A. Loosen the hub bolts 3. Oil level too high |

1. Replace the floating seal assembly A. Tighten the bolts to the standard torque. 3. Drain excess oil to the standard level. |

| Brake failure | 1. Insufficient brake fluid A. Excessive wear of brake pads 3. Hydraulic line clogged |

1. Top up the brake fluid and exhaust gases A. Replace the brake pads 3. Clean or replace the brake fluid.highway |

| Differential lock malfunction | 1. Differential lock solenoid valve malfunction A. Fork wear 3. The air pressure is less than |

1. Replace the solenoid valve A. Repair or replace the fork 3. Check the air source and adjust the pressure. |

3. Follow safety regulations

Before performing maintenance work, you must stop and turn off the fire, apply the parking brake and place a vehicle chock under the tire.

When changing the oil, the drive axle must be cooled to ambient temperature to prevent high-temperature oil from burning.

When using lifting equipment, qualified support devices must be used and it is strictly prohibited to rely solely on hydraulic jacks to support operations.

During inspection during disassembly, the parts must be disassembled in accordance with the installation marking and the installation location must be indicated.

After maintenance is completed, a 30-minute no-load test run is required to confirm that there is no fault before the unit can be put into service.