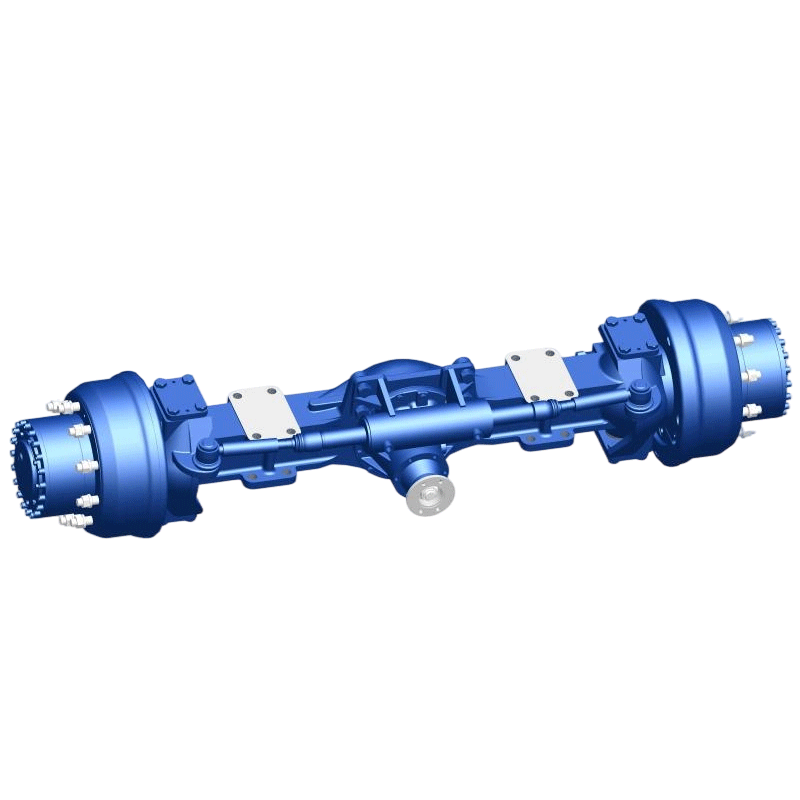

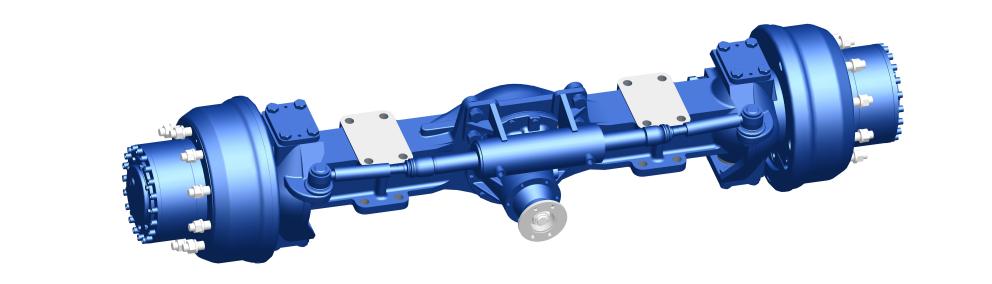

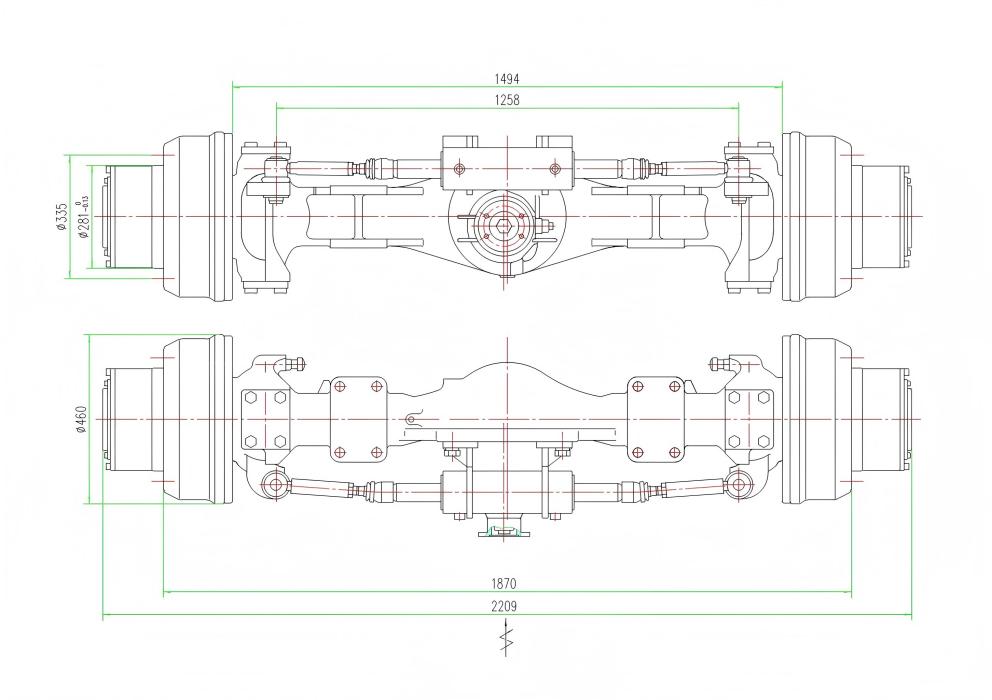

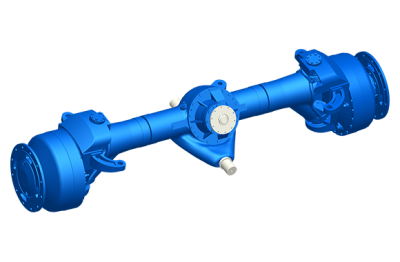

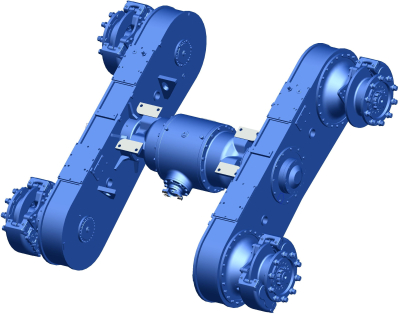

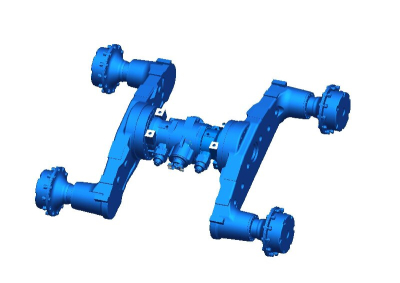

Drive axle for a 12-ton wheeled excavator

1. Direct deliveries from the manufacturer without increasing prices through intermediaries

2. The drive axle is available

3. Urgent orders may be given priority

4.Product customization is possible

5.24-hour online after-sales service team

Main characteristics:

In the field of construction equipment, the leading bridge, as the main component of the transmission, is directly related to the efficiency of capacity, stability and service life of the equipment. The host of the bridge of our 12-ton wheel excavator is specially designed for wheel excavators, taking into account the requirements of high intensity of work and flexible mobility and is suitable for various difficult working conditions, such as mining beneficial,, of the mining of healthy. Construction and municipal management.

production :

The leading bridge is equipped with a high -strength gearbox, optimized by a differential and an effective brake system, which significantly reduces energy consumption and ensures the transmission of torque. The bridge corps was strengthened using integrated leaflet technology and analysis by the final elements, and its impact resistance was increased by 30%, which allows you to effectively cope with frequent vibrations at the crossed areas. In addition, the improvement of sealing allows us to adapt to extreme environmental conditions and reduce the frequency of maintenance.

The braking system from the wheels uses the NGW planetary transmission developed in the industry, which has a large gear ratio, small dimensions and high carrying capacity. It can additionally slow down and increase the torque from the chief gearbox, so that the wheels can receive a larger torque and adapt to traffic conditions. 12-ton excavators are designed to work in difficult conditions.

The main technical parameters:

Common gear ratio |

16.89 |

Maximum input torque |

2535N.m |

The nominal load of the bridge |

13000Kg |

The method of steering |

Hydraulic steering |

Brake system oil pressure |

12.5MPa |

The moment of braking of one side |

10900N.m |

The working volume of a one -sided brake |

14ml |

Flip requirements for the leading bridge (API classification) |

GL -5: 85W/90 transmission oil (use at temperatures above -12 ° C) GL-5: transmission oil 80W/90 (use at temperatures above -26°C) |

Brake Oil Requirements |

Hydraulic oil with anti-wear and low-freezing properties L-HV46 |

technology:

Our company has been specializing in the production of leading bridges of construction equipment and confidently leads in the industry: it has 2 intellectual production lines equipped with the German Siemens PLC control system for automated processing of key processes on leading bridges with an accuracy of determining 0.001 mm and high accuracy of control. The stable level of product quality is more than 99.8%; The company has the Center for Technological Research and Development, and the main personnel of the research and development department has more than 10 years of design experience and received a number of patents for useful models related to leading bridges. The company has passed the main system certificates, and its products occupy a stable share in the Russian and Central Asian markets. It provides support services for leading bridges for local Russian brands UMG, PTZ, etc. Our products showed excellent performance in Russia, achieved good results with a zero level of accident and a long service life. Long-long cooperation with the largest manufacturers of equipment.

Given the difficulties of operating 12-ton wheeled excavators, we formed a special team of developers to complete the iterative design of the leading bridge, taking into account the actual operational data of the customer, optimize structural parts and, finally, the passage of bench tests and 500 hours of operation in the field of Verification presented this leading bridge with wide adaptation capabilities, high strength and strong strength and strong strength and strength and strength and strength Reliability in work, and also seeks to help customers solve the problem of refusal of the main components and reduce operating costs.

Delivery :

Logistics and services: to provide you with safety and convenience

Goods sent to Russia need not only high -quality products, but also reliable logistics support .:

Packaging Protection: The product is packed in a strong wooden box with moisture-proof coating, which can effectively avoid damage from shock and changes in temperature and humidity during transportation.;

Logistics partners: Cooperate with large logistics companies that are active in the Russian market - delivery times are short and the goods can be received within 30 days

Customs Declaration Services: We have professionals who follow the customs declaration procedures throughout the entire process.

Exclusive service:

In addition, we have created an exclusive service support system for Russian customers:

Professional technical consultants provide communication services in Russian

Please provide the Russian version of the operating manual and the structural diagram

After-sales warranty, constant supply of spare parts allow you to quickly respond to maintenance and replacement needs

We know that your business is not only about the price of the product, but also about reliability, adaptability to local conditions and efficient service. Our company can provide you with:

Adapt exclusive solutions for your equipment model;

Flexible payment terms for large volume orders;

We invite you to visit the production base and see the quality on site.