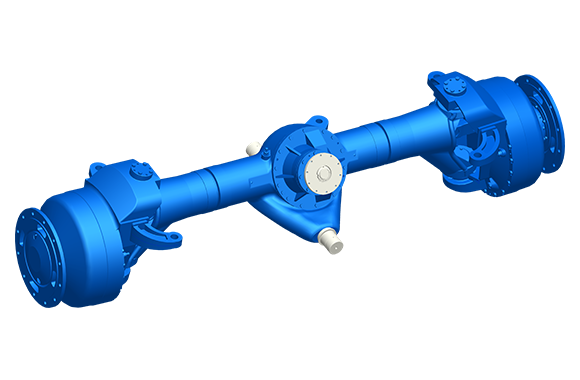

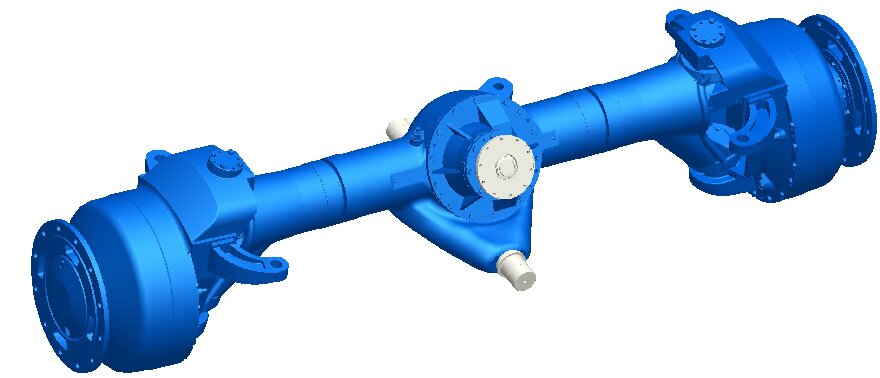

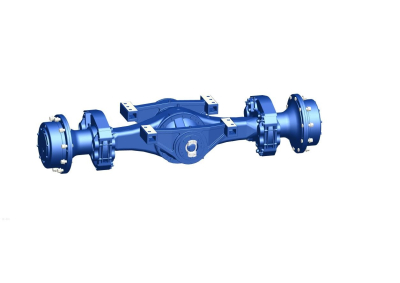

Front steerable drive axle for grader

1.Control method - hydraulic steering

2.Dirty and 100% non-slip

3.Reliable and high quality, exported to Russia in large quantities

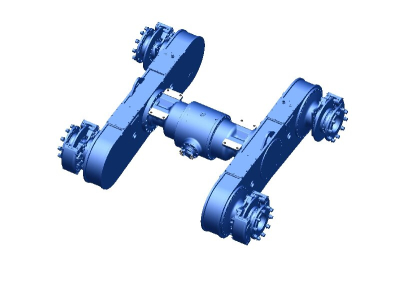

4.The vehicle's cross-country ability is significantly increased

5. The bearing capacity of the bridge shell is rigid

Introduction:

The front steering axle of the Grauder Shandong Lutong is a high -performance leading bridge specially designed for graders. It uses advanced production technologies and high -quality materials to ensure stable and reliable operation of the engine and steering in various difficult operating conditions. The host of the bridge not only has excellent carrying capacity and durability, but can also significantly increase the efficiency and operational flexibility of the grader, which makes it an ideal choice in the field of construction equipment. The host is suitable for various operating conditions, whether it is soft The soil, gravel or solid road surface, and can work in any conditions. Its excellent sealing properties effectively prevent the ingestion of such pollution as dust, dirt and water, and ensure prolonged stable operation of the main components.

Being a well -known brand in the field of construction equipment, Shandong Lutong has always sought to provide customers with high -quality and high -performance products for leading bridges. We have developed production technology and a strict quality control system that each leading bridge can satisfy the most demanding requirements of customers. Having selected a leading bridge with a front -line rudder, you choose you choose Effective, reliable and durable technical solution.

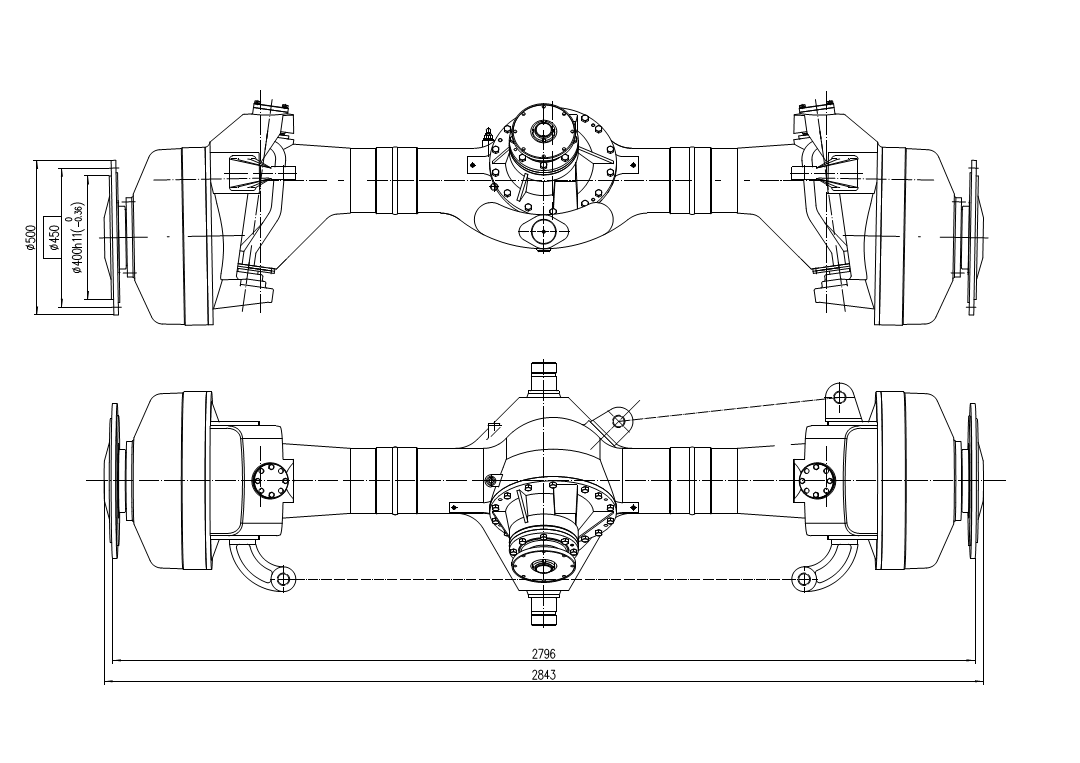

The main technical parameters:

Common gear ratio |

17.357 |

Maximum input torque |

6100N.m |

Maximum input frequency of rotation |

3450r/min |

The nominal load of the bridge |

18800Kg |

The angle of rotation |

±31º |

The method of steering |

Hydraulic steering |

Flower requirements for the leading bridge (API classification) |

GL-5: transmission oil 85W/90 (use at temperatures above -12°C) GL-5: transmission oil 80W/90 (use at temperatures above -26°C) |

The front drive axle of Shandong Lutong motor grader is equipped with an advanced steering system, which enables precise steering, ensuring the flexible operation of the motor grader in narrow or complex terrain. Its steering mechanism is responsive and easy to operate. So, what is the difference between the steering drive axle and the ordinary drive axle?

In the field of construction technology, the differences in the design and application of steering drive axles and conventional drive axles are particularly significant. The following is a detailed comparative analysis of construction equipment.:

1. Differences in functions and working conditions

property |

Steering axle drive |

Conventional drive axle |

Drive + steering |

Realize power transmission and wheel steering at the same time |

Provides power transmission only, no steering function |

Applicable equipment |

Front axle of grader, forklift, off-road crane, etc. |

Rigid frame road roller, asphalt paver, drive axle without steering |

Typical Working Conditions |

Frequent control, work in a small space |

Driving straight or at low speed |

2. Performance comparison

pointer |

Steering axle drive |

Conventional drive axle |

Load capacity |

Medium, steering flexibility needs to be taken into account |

Design with extremely high load-bearing capacity, e.g. for shaft axles |

Steering wheel angle |

important |

not to be |

Maintenance costs |

height |

Low, simple design, low failure rate |

Adaptability to terrain |

Ideal for small spaces and uneven roads. |

Good, suitable for stable linear work |

3.When choosing a bridge type of construction equipment, it is necessary to consider the key factors influencing the choice of type:

Operation scenario: Select the steering drive axle for frequent turning and select the normal drive axle for straight section operation with high load.

Cost control: The maintenance cost of the steering drive axle is higher, and the normal drive axle is more suitable for long-term operation under severe conditions.

Technological modernization: In the context of the trend towards electrification and intellectualization, the use of a steering drive axle with an integrated motor has become a new direction