Upgrading engineering equipment to enhance its durability - Shandong Lutong steering drive axle ensures the efficient operation of multi-model main equipment.

Currently, when the construction industry is on the rise, the advantages and disadvantages of the productivity of basic equipment are closely related to the quality of the main components. As the enterprise specializing in research, development and production of leading bridges, we rely on deep technical knowledge, modern production equipment and strict quality control in order to offer highly effective solutions for steering leading bridges for various wheel excavators, Excavation-loading machines and other basic equipment, successfully helping customers increase equipment productivity and win the market recognition. Next, I will tell you in detail about several typical cases of use and demonstrate excellent operational characteristics and high strength of the company's leading bridge in real operating conditions.

Example 1: The use of the leading bridge of the steering wheel controlor to adapt to stable performance in difficult working conditions

A well -known manufacturer of construction equipment has long been engaged in research, development and production of wheel excavators of small and medium size. Due to its excellent flexibility and effective operational capabilities, its equipment is widely used in utilities, landscaping of agricultural land and in other areas. However, these complex and variable operating conditions impose strict requirements for the characteristics of the leading bridge. It must have not only excellent flexibility in order to cope with work in a narrow space, but also with a high carrying capacity and excellent strength to withstand frequent blows.

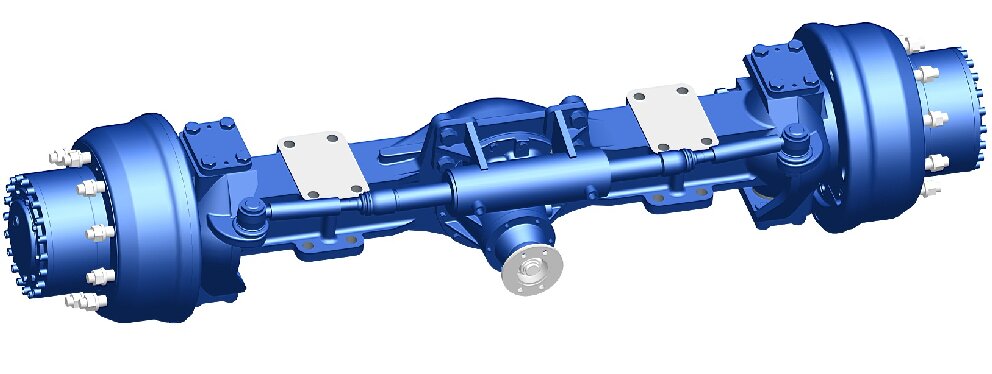

Having received a request from the customer, we quickly formed a professional technical team for an in-depth study of the characteristics of the working environment and the requirements for equipment performance and, finally, recommended the customer the leading bridge of the 12-ton wheel excavator (12-ton leading bridge of the wheel excavator). The structure of the leading bridge fully takes into account the balance between low weight and high strength. In the design of the bridge, materials from high -strength alloys were used. Due to the optimization of the structure, the weight of the bridge case is reduced with a simultaneous increase in its impact resistance and fatigue resistance. Operational characteristics. Considering the features of wheel excavators associated with “high -frequency control and work in difficult conditions”, this product uses enhanced gears to increase the efficiency of transmission and effectively reduce power loss. The corresponding imported oil seals provide continuous work in harsh conditions, such as dirt and swampiness. Unavailable work. In the production process based on the advanced technological equipment of the company, the bridge case is subjected to accurate mechanical processing, which ensures extremely high accuracy of the assembly of the components, effectively reducing wear and energy loss during operation.

After commissioning commissioning, long -term actual measurements were carried out in difficult operating conditions, such as polluted agricultural lands and construction sites of urban infrastructure. The results show that the wheel excavator equipped with a leading bridge has an extremely sensitive reaction to the steering and can easily turn on narrow agricultural paths and urban urban the streets, which significantly increases the efficiency of work. After 8 hours of continuous operation, the temperature of the axis housing was stabilized below 65 ℃, the operational characteristics of the lubric oil did not decrease significantly, and the wear of all key components was controlled at a very low level, which fully confirms the reliability of the cooling and sealing system of the leading bridge. Customer reviews show that after using the leading bridge, the frequency of refusal of the refusal Equipment decreased by 40%, and the total efficiency of work increased by 25%, which brought significant economic benefits for business development.

Example 2: Support for the drive axle steering of a backhoe loader considering heavy load and control flexibility

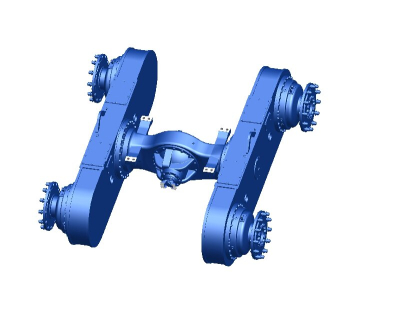

Due to its characteristics of the “one machine and the many functions”, the excavator-loader has become an indispensable assistant in the construction of small and medium facilities. He can not only effectively carry out loading and unloading work from the front, but also flexibly perform earthen work from the back. A frequent change in the working bodies creates a double problem for the work of the leading bridge. On one side, during heavy earthwork, the leading axis should withstand huge longitudinal loads in order to ensure the stability and reliability of the equipment; On the other hand, in the process of moving short distances from the leading axis, a flexible steering is required to adapt to various scenarios of operation.

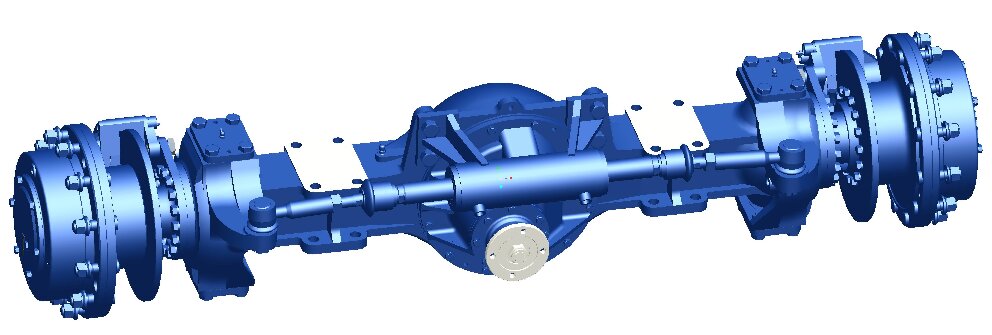

The working conditions of the excavator-carrier are relatively specific, therefore extremely high requirements are made to choose the leading bridge. After numerous tests and comparisons, the customer finally stopped his choice on the branded 13-ton steering axis. At the beginning of the design of the leading bridge using mechanical analysis, the load on the bridge frame was calculated, and various conditions were simulated for the modeling for modeling. The work, and then, in accordance with the results of calculations and modeling, the key elements of the bridge frame were strengthened, which increased the bearing capacity and fatigue of the drive resistance. The account of optimizing the shape of teeth and the material from which the gear was made, its bearing capacity increases by 20% compared to the industrial standard. Due to the optimization of the hooking mechanism parameters of the wheel braking mechanism, the gear bearing becomes more balanced, and the service life increases. Extracts easily cope with a huge torque and shock force during excavation in severe conditions, ensuring smooth movement of equipment.

In the process of production, each component of the leading bridge should take strict quality control. The last thing, pollution and oil spots on the surface of the parts are removed using ultrasound automated cleaning lines to ensure the cleanliness of the details; Then, during the assembly process, strict assembly operations are performed in strict accordance with the technological documentation and key indicators, such as the preliminary tightness of the bearings and the gear engines are checked to make sure that all indicators meet the requirements. After the assembly is completed, it is necessary to conduct tests requiring the reliability of all connections, lack of noise, stagnation, overheating and leaks. All test indicators comply with factory standards. After the product is developed, it first enters the National Laboratory

Thorough stand tests passed. In practical use, the excavator-loader equipped with a leading bridge demonstrated excellent operational characteristics. The customer noted that after using the leading bridge, the overall equipment performance reached the level of the world class, and the purchase costs decreased by 18%, which is a significant advantage in terms of market competition.

Behind all these successes are our comprehensive support in the field of research, development and production of leading bridges.

Strong team on research and development:

We have a team on research and development, consisting of more than 60 middle and senior specialists. They have deep professional knowledge in the field of mechanical design, materials science, hydraulic transmissions, etc., paying special attention to the optimization of the structure and increasing the performance of leading bridges of construction equipment. The commands pay close attention to the latest technological development in the industry and changes in market demand and continue to introduce technological innovations, conduct research and development of products. Each year, more than 10 new patents are added, which provides a constant flow of energy to modernize the company's products and technological progress.

Intellectual production system:

The company has invested significant funds in the introduction of advanced international equipment for automation, such as the Swiss ABB robots and Japanese Fanuc robots, and built an intelligent production line with a full production cycle - from processing parts to assembly. This is modern equipment allows high -precision and highly effective production operations, effectively increasing the consistency of products and stability The same time, thanks to the intellectual production management system, monitoring and analysis of the production process in real time is carried out, and production problems can be detected and resolved in a timely manner to ensure a constant increase in production efficiency and product quality.

Strict quality control:

Quality is the basis of the life of the enterprise, and we always carry out quality control throughout the production process. In the production process, each leading axis must pass a number of strict tests, including checker checks, checking the processing process of parts and checking after assembly. When the purchase of raw materials, we strictly check suppliers to guarantee that all raw materials complies with high quality standards; In the process of processing parts, advanced testing equipment and technologies are used for monitoring and setting up key parameters, such as size accuracy and surface roughness, in real time; After the assembly is completed, during more than 10 precision tests, the operational indicators of the leading bridge are comprehensively checked, and only products that have passed all tests can enter the market.

Currently, our drive bridges with steering are widely used in various units, such as wheeled excavators and excavator-loading machines. Thanks to excellent performance and reliable quality, we have won a good reputation in the market. The production of the company is 50,000 root crops per year, which allows you to fully satisfy customers' needs in wholesale orders and provide timely and effective products.

If your equipment requires a high -performance and high -quality solution for the leading bridge, please do not hesitate to contact us. Blagodary of a professional technical team, modern production equipment and a strict quality control system, we develop the most suitable products for leading bridges to help your products stand out against the background of competitors in the market and increase commercial value. Come work together to work together to create the best The future for the industry of construction equipment!

- Previous : Intelligent technological production lines ensure the quality of the drive axle and establish a solid foundation for quality assurance with international equipment.

- Next : Rigorous bench testing to verify superior performance: Lutong Heavy Industry's modular forklift telescopic handler axle is a leader in technological innovation