Rigorous bench testing to verify superior performance: Lutong Heavy Industry's modular forklift telescopic handler axle is a leader in technological innovation

In the National Authoritative Laboratory, the recently developed modular leading bridge of the steering company Shandong Lutong Heavy Industry Machinery Co., Ltd. Complex tests at a systematic stand are undergoing. This innovative product demonstrates the power of Chinese intellectual production for the industry due to its excellent characteristics. By the main component specially designed for loading telescopic forks, the leading bridge with its highly modular structure not only redefines the technical standards of the introductory vehicle, but also will bring revolutionary changes in the entire industry.

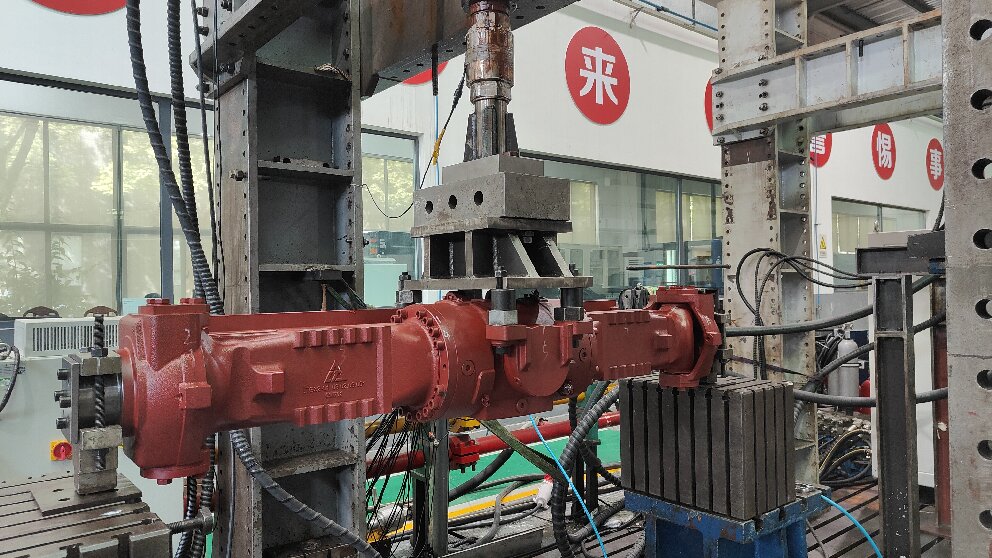

Stand tests of the leading bridge: checking reliable quality in accordance with the highest standards

This systematic bench test is based on the advanced capabilities of the national laboratory and uses testing scheme that far exceeds the industry standards of testing. The company's test program imitates extreme conditions that are more demanding than real working conditions, and its goal is to test the reliability and durability of the product in the most severe conditions. This is not only technical verification, but also to fulfill the promises of the client.

The test of the bridge frame for vertical stiffness using a hydraulic servo system imitates extreme operating conditions in difficult conditions, which allows you to check the stability of the leading bridge for deformation and ensure the stability of the structure with prolonged use.

The test of the bridge case for fatigue with a vertical bend was even more shocking. The testing of a million cycles of this dough in a million strokes that the product may encounter throughout the service life. The load significantly exceeding the actual operating conditions allows you to assess its fatigue strength and durability with prolonged high -frequency loads.

The test of the fatigue strength of the leading bridge in the collection mainly checks the ability of the leading bridge to be assembled to stabilize the power of the dentate transmission system in extreme conditions with a high torque and high speed. During the test, a unique stepped loading mode is used, at which the final value of the torque significantly exceeds the fixed value. The aim of the test is to check the strength, reliability and effectiveness of the gear system.

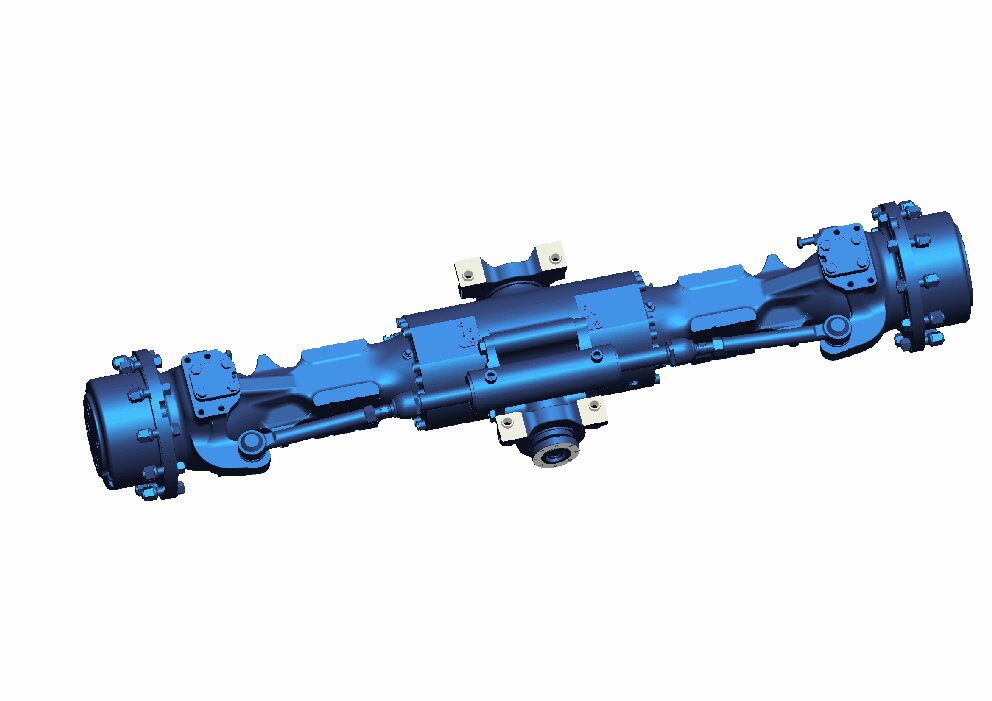

Modular design of the leading bridge: rethinking the technical boundaries of the industry

The innovative value of the leading bridge is reflected not only in the results of the tests, but also in the revolutionary design concept.

Powerful design features make it perfectly adapted to high load and frequent loads on the steering of telescopic forks. The production is made of high -strength cast steel, the design is optimized using a computer, and the supporting ability of the product is significantly improved.

The modular design allows you to quickly replace the brake modules, differentials in the collection and mechanisms of side braking of the wheels of various technical characteristics. This design not only perfectly corresponds to the needs of the main manufacturers of the equipment, but also flexibly adapts to more than ten types of special equipment, such as wheeled excavators, excavator loaders and lifting and transport platforms. Modular platform allows. Satisfying the most diverse needs, and customers no longer need to reserve various spare parts for various equipment, which will save customers more than 30% of the costs of purchasing and storage.

The concept of reliability permeates the entire process of design, material selection, manufacturing and testing. We always adhere to the highest standards and strive to be the most reliable source of power transmission for your equipment.

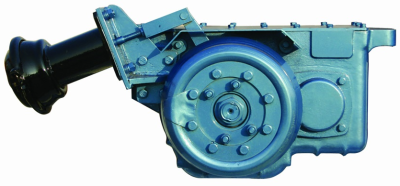

Original production: 30 years of work to achieve excellent quality

As an enterprise specializing in research, development and production of leading bridges for more than 30 years, the Shandong company for the production of equipment for heavy industry Lutun has always insisted on technological innovations that contribute to the development of the industry. The company has passed the certification of high -tech enterprises and received more than 70 national patents of various types. Successful research and development of this product.

The general director of the company said: “From storage of raw materials to the supply of finished products, we must go through more than 100 quality control processes. Coming the leading axis should pass dozens of special tests, such as checking the accuracy of size, hardness and cleanliness. Such a constant desire for quality allows our products to maintain the most stringent tests.”

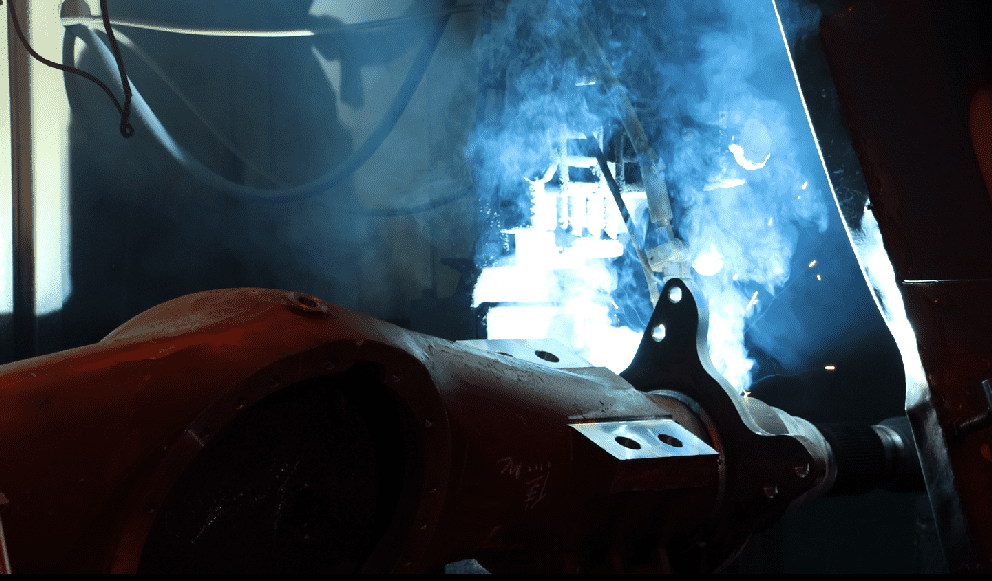

The intelligent production line implemented in the production base is the key to quality assurance. Automated machining centers ensure high precision machining of key components, and robotic welding stations ensure stable weld quality.

The strength of the witness being tested determines the future

Currently, the trial is still actively moving, and we are full of confidence in it. The focusing data of this bench test allow not only to confirm the reliability of the product, but also to lay an important basis for the subsequent optimization of the product. During the test time, the temperature sensor is used to track the distribution of temperature in real time, and the vibration sensor records the slightest changes in vibration. These data allow us to get a complete picture of the work of the product in extreme conditions.

Prospects for use: the possibility of modernization of multidisciplinary equipment

The prospects for the use of this carefully tested leading steering bridge are very promising. In the area of port logistics, it can provide high power and accurate control of the loading of containers with a fork; In the mining industry, it can help large equipment to cope with difficult working conditions; In construction, he can provide reliable protection of lifting working platforms.

We cooperate with a number of leading domestic equipment manufacturers, and the first batch of leading bridges with telescopic forking gear will be installed on the latest Smart loaders. Clients especially appreciate our modular structure, which allows them to satisfy more needs in equipment with a fewer types of spare parts. In the future we will continue to demonstrate the effectiveness of this product in practical applications, such as portables. Logistics and mining mining, and we will use the undeniable test data to protect the performance of your equipment and operation safety. Come go hand in hand and promote the great transformation "made in China" in China!