Intelligent technological production lines ensure the quality of the drive axle and establish a solid foundation for quality assurance with international equipment.

In the field of production of modern construction equipment, intelligent technological automatic lines have become a key element determining the competitiveness of enterprises.It is not only a key tool for improving production efficiency, but also an important support for ensuring the accuracy and consistency of products.It is directly related to the stability of performance and service life of parts, and has an irreplaceable impact on enterprises in terms of market expansion and brand reputation building.Shandong Lutong Heavy Industry Machinery Co., Ltd.has a good understanding of the core values of intelligent manufacturing and regards first-class and advanced intelligent automatic processing lines as an important cornerstone of its development.The company uses an automated production system consisting of manipulators of world -famous ABB, Fanca, Kuka, Kuka and others, in cooperation with high -precision machines, in combination with the possibilities of monitoring and analyzing data in the mode of intellectual production management systems to achieve high accuracy and production efficiency in the field of processing the main details of construction equipment, as well as providing provision consistency and stability of products throughout the entire process of quality control and the establishment of the quality of the quality.

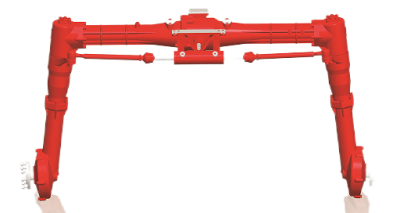

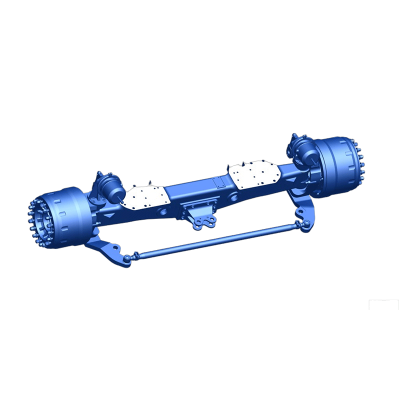

The intelligent technological automatic line Shandong Lutong has a comprehensive layout covering the production line of intellectual processing of the bridge case, the production line of intellectual processing of the bridge lever, the production line of the planetary wheel frame, the production line of intellectual reducer housing, the production line of intelligent processing Shell differential and intellectual welding line, etc., precisely satisfy the needs for the processing and molding of key details of construction equipment.

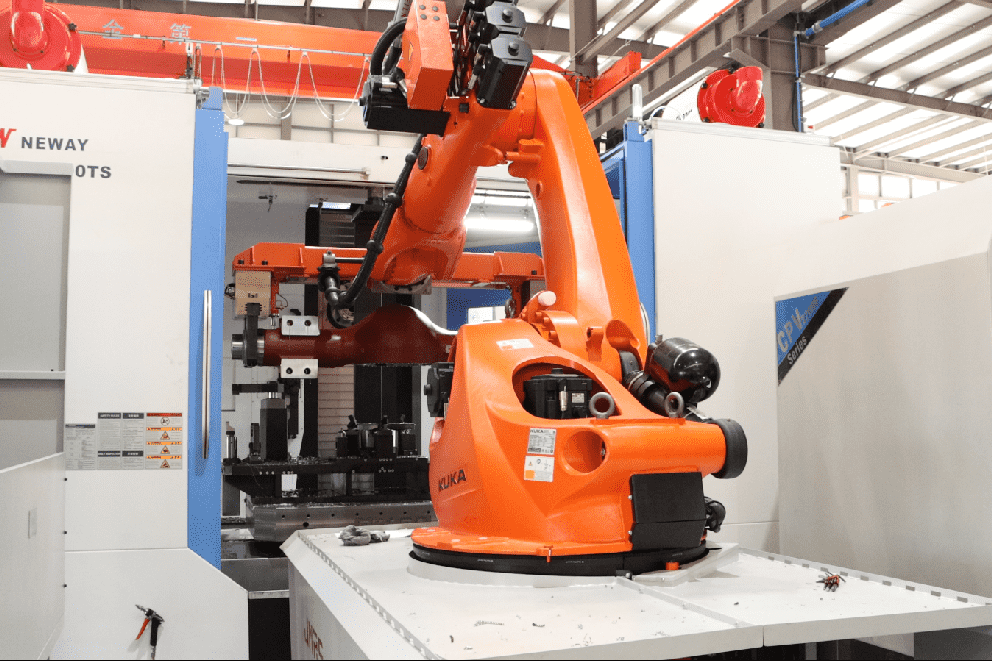

As the supporting frame of the leading bridge, the accuracy of processing the axis housing is important. On the intellectual technological line of the Bridge Shell, the KUKA manipulator is responsible for the exact transmission and positioning of the parts, and the key processing processes, such as drilling and pulled out, are performed on high -precision CNC management machines. processing process, such as cutting force, spindle rotation frequency and feed rate. If small deviations are detected, the system automatically issues an early warning, and the parameters of the machine can be dynamically adjusted to avoid error accumulation. This mode "Accurate positioning of manipulators + Precision processing of the machine + control of the system in real time" strictly controls the accuracy of processing at the micron level, which is rooted in the root and reduces the probability of rejection More than 90% compared to traditional production, a model that lays a strong basis for the supporting characteristics of the leading bridge.

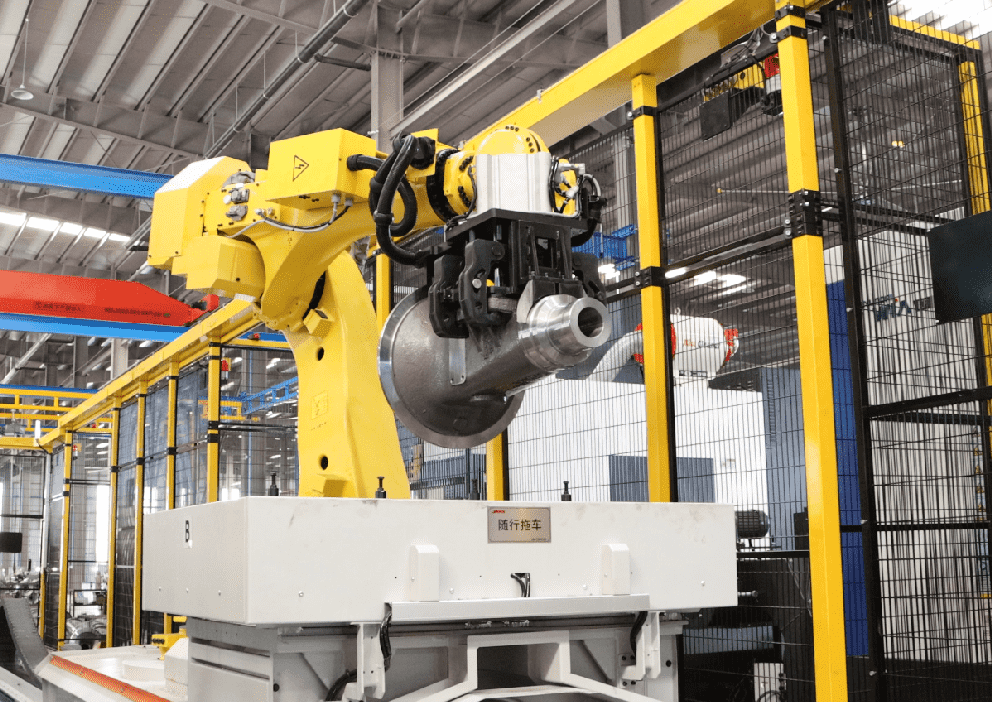

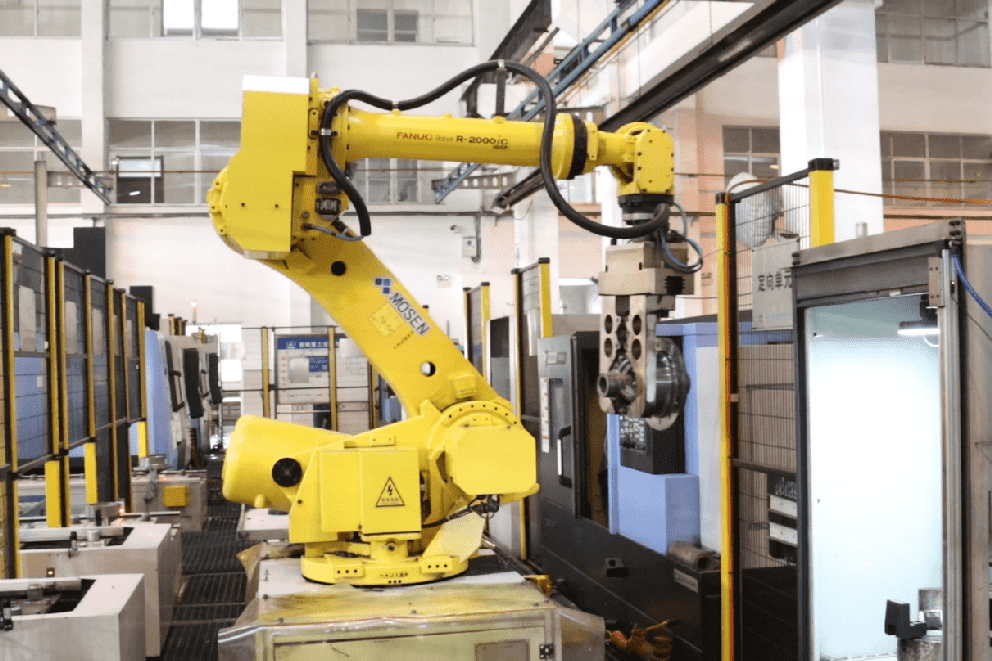

The axis lever is the key component of the leading bridge that transfers torque, and its curved surface is complex in processing. The intellectual technological line of the Bridge ARM is equipped with FANUC manipulators for the effective movement and positioning of parts between different machines, while such processing processes as milling and removing of the facilities are precisely performed on special machines. Analyzing the historical data on processing, the intellectual system automatically optimizes the path of the tools and cutting parameters to ensure a high consistency of the trajectories of processing of various parties of parts. Compared to traditional manual control, this automated regime completely eliminates the influence of manual errors, which allows qualitatively increasing the accuracy of the size of the bridge lever, and the deviation from the bridge lever, and the deviation from The uniformity of the same batch of products is controlled within 0.02 mm to ensure the stability of the power transmission of the leading bridge.

The planetary wheel frame is the “central sleeve” of the transmission of the drive bridge, which requires high processing accuracy. The intellectual production line of Shandong Lutong in the processing of planetary wheel frames is equipped with the ABB manipulator, which is responsible for the entire transportation and positioning process. The flow of material from loading blanks to control of finished products is accurate and controlled, and the main processing process ends using high -precision special machines. The intellectual production management system synchronously gets access to the data of a three -coordinate measuring device to determine the alignment of the mounting openings of each dentate and immediate feedback and the correction of the trend exceeding the standard standard The value, as soon as it is detected. The reduction accuracy of the re -positioning of the manipulator in combination with the dynamic calibration of the system allows you to stably control the error error within 0.01 mm to ensure the effectiveness of the transmission and stability of the leading axis.

The housing of the main gearbox and the differential case are key elements that ensure the inhibition and twisting of the leading bridge and differential transmission. During the processing time of the main gearbox, the manipulator exactly delivers parts to the processing station, and the CNC machine completes the processing of key parts, such as bearings for bearings and threaded holes. The system collects data such as the cutting temperature and the frequency of vibration, in real time, predicts the degree of wear of the tool using the algorithm models and reminds in advance of the replacement in order to avoid processing defects; On the line for the production of differential buildings, Fanuc manipulators are used due to high -speed and stable transportation and positioning on special machines for processing the intellectual system creates a full database on the quality of the batch, compares and analyzes the data and automatically optimizes the parameters that ensure high quality processing of each case and stable output of the product at 99.5%. All this fully complies with the strict requirements of the leading bridge for the accuracy of the transmission.

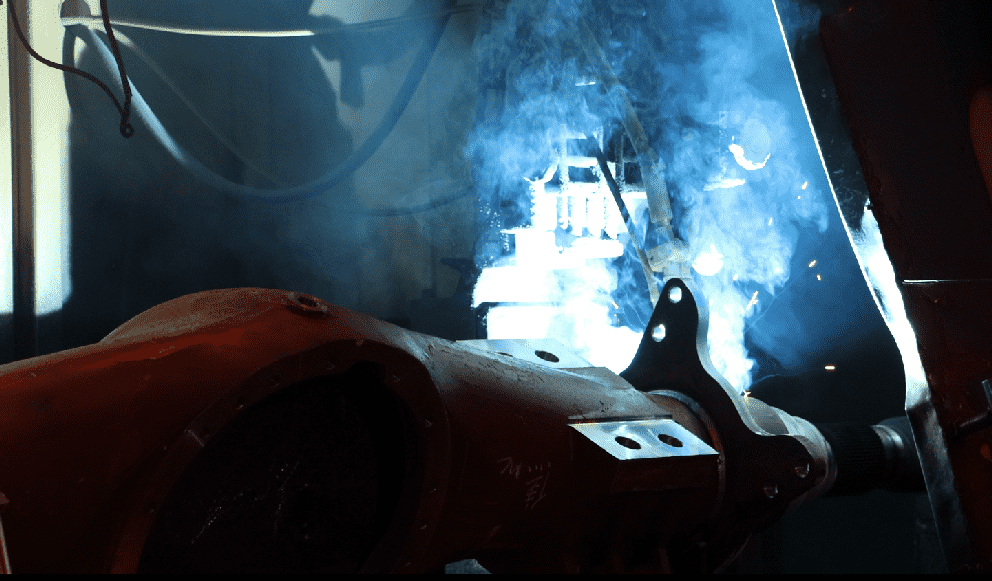

Shandong Lutong also has a special intelligent welding line for the leading bridge. The robot is responsible for the positioning and welding of key seams. The intellectual system controls the welding current, voltage, temperature in the bath and other parameters in real time and determines the state of the weld using visual recognition technology. As soon as if there are problems such as virtual welding and welding with leakage, they are immediately suspended and warned. The system records technological data for each weld in the form of a monitoring file, which allows the process to optimize the process of welding strength to 99.8% and guarantees the integrity and durability of the entire structure of the leading bridge.

For a long time, the company Shandong Lutong considered the quality of products manufactured for leading bridges for its enterprise. This is intellectual technological lines built around the production of the leading bridge, in combination with the possibilities of monitoring and analysis of data in the intellectual production management system, the quality control system creates a system of control of the entire process. Automated production reduces the influence of the human factor more than At 70%, the accurate movement and positioning of the manipulator provides stable processing indicators on the machine, the system monitors real -time and solve potential problems in a timely manner, and the entire process is digitized and amenable to tracking. The finished product is well documented, and the process is constantly optimized due to the constant data analysis, which contributes to a steady increase in the quality of the leading bridge.

The first -class quality of leading bridges was widely recognized by leading domestic manufacturers of construction equipment, such as Sany, Shantui, Lovol, etc., which established stable cooperation relations with the Shandong Lutong. In the Russian market, the company also successfully collaborates with such well -known manufacturers as PTZ and UMG. These companies make almost the most stringent requirements for the quality of leading bridges. The main reason for the choice of Shandong Lutong is the excellent characteristics of its products in terms of accuracy, stability and durability.

Thanks to the advanced automatic lines and the reliable quality of leading bridges, Shandong Lutong continues to demonstrate its efficiency in the production of leading bridges. In the future, the company will continue to deepen the integration and use of intellectual production lines and control systems, will further increase the international competitiveness of products for leading bridges and will provide customers around the world with high -quality solutions for the whole world leading bridges of construction equipment.