Conquer the highest power: the high-performance drive axle, specially designed for forestry machines, has been officially tested

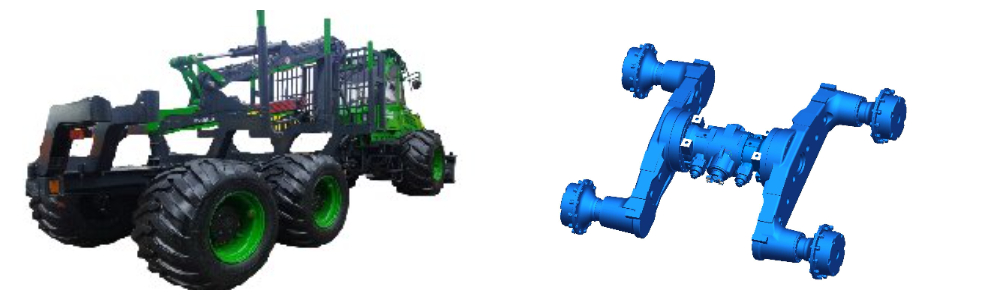

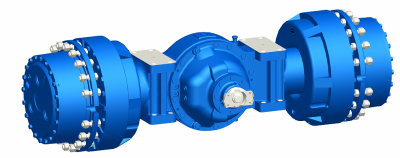

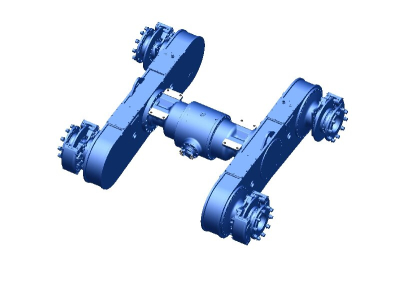

In today's rapidly accelerating global forestry mechanization, high-performance and reliable specialized equipment has become a key factor in improving the efficiency and safety of forestry production.As a vital transport hub in the forestry industry, harvesting machines (or logging vehicles) travel year-round through virgin forests and mountainous areas with challenging terrain and harsh conditions.The performance requirements of the main transmission component, the drive axle, are incomparable to those of conventional construction equipment.Facing the challenges of this industry and relying on years of experience in the R&D and production of heavy-duty drive axles, our company has successfully launched the LTP75 series drive axles, designed for modern material collectors.The product has not only been tested for extreme operating conditions in a reputable national laboratory, but has also demonstrated excellent adaptability to real-world forestry work.It redefines forestry drive system performance standards with innovative features such as the rocker arm design, large offset design and four-stage high-speed control system.gear ratio.

1. Born for Extreme Conditions: Addressing Key Forestry Working Conditions Issues

When using traditional drive axles in forestry machinery, they often encounter a number of insurmountable obstacles: first, the road surface in forested areas is uneven, the roots are irregular, and the mud is slippery, which seriously affects the ground clearance and maneuverability of the drive axle; secondly, the heavy load of timber towing operations requires a constant and huge traction torque, which is the main test of the strength and durability of the transmission system; third, when working on steep slopes and side slopes, it is necessary to have excellent anti-skid and body stability control equipment to ensure safe operations; fourthly, long service life. - prolonged exposure to humidity, dust and temperature changes in the environment with sudden changes requires the drive axle to have exceptional seal reliability and adaptation to the environment.

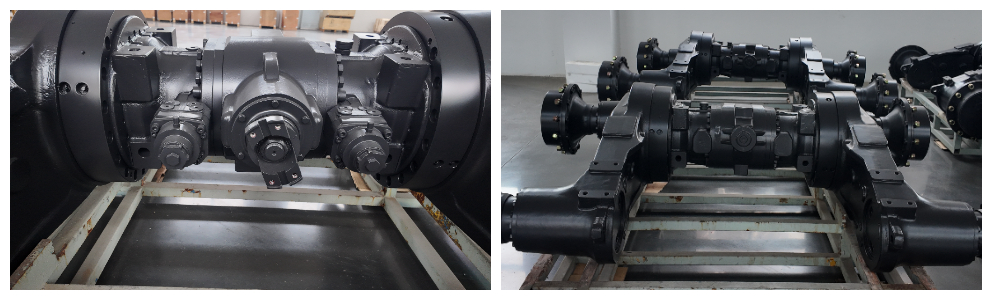

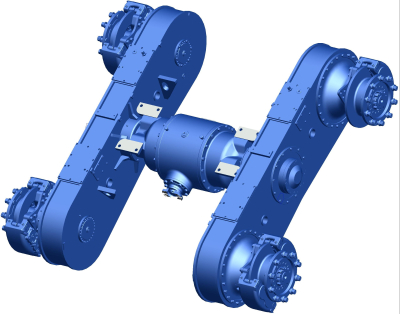

To overcome these problems, our research and development team conducted in-depth field research on a number of large forestry farms at home and abroad, and also carried out in-depth exchanges with senior equipment operators and maintenance engineers. Based on first-hand knowledge of operating conditions and user pain points, the core design concept of the drive axle of the LTP75 series forestry machine was developed: “Ultra-high flotation, exceptional traction and absolute reliability.” Starting from the conceptual design stage, the product refuses the compromise of a common platform and develops in accordance with the special mission of forestry equipment. Its iconic balance box design flexibly connects the axle housing to the gearbox using precision swivel bearings, so that the wheels can perfectly adapt to uneven ground conditions, maintain balanced tire pressure and significantly improve flotation and ride smoothness in extreme road conditions such as stumps and ravines. This is its main advantage over traditional rigid bridges.

2. Technological deconstruction: Four core innovations deliver superior performance

1. Design with a large slope and a balancing box: restoring the passability limit

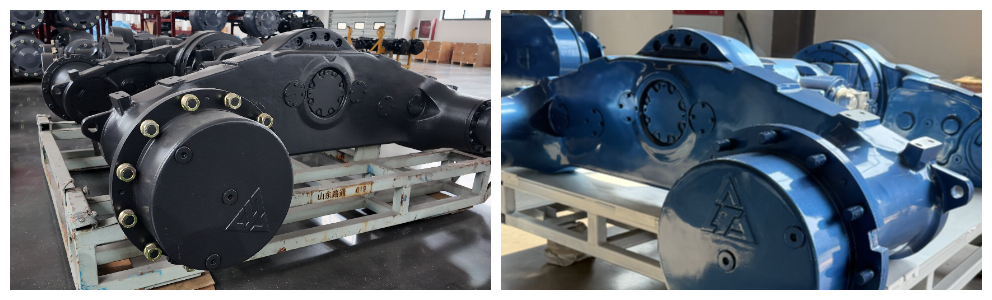

The most striking feature of the LTP75 drive axle is its revolutionary high-rake design. The centerline of the power delivery shaft is strongly raised, creating a significant distance from the center of the tire. This design directly provides two decisive advantages: first, the vehicle's minimum ground clearance has been qualitatively increased, so that key components such as the drive axle main body and differential can easily overcome the most common obstacles on the road in the forest area, which significantly reduces the risk of “bottom support”; The second way is to optimize the distribution of the vehicle's center of gravity, thanks to the balancer rotation function, the stability and safety of the vehicle during side tilt operations is greatly improved. The transmission inside the balancer is not a simple chain drive, but a more precise and efficient gear transmission system, which ensures flexible power distribution while improving transmission efficiency and extending service life.

2. Four-stage high-rpm deceleration mechanism: ease off the Majestic traction

Due to the excessive load on the material picker hauling giant wood, the conventional secondary or tertiary braking mechanism is often unable to catch it. The LTP75 drive axle is innovatively equipped with a four-stage high-rpm retardation system. This system features a clever torque amplification design between the main gearbox and the wheel-side gearbox, resulting in the overall gear ratio reaching the highest level in the industry. The most obvious The advantage it provides is that with the same engine power, it can produce higher torque at the wheels, providing the equipment with traction similar to “climbing up a mountain and carrying a tripod”. Whether it is climbing a steep slope or self-rescuing after you get stuck in a quagmire, the powerful torque reserve ensures the ease of use of the equipment. At the same time, precisely calculated and optimized gear meshing parameters ensure that when huge gear ratios are achieved, transmission efficiency is maintained at a high level, thereby avoiding unnecessary power losses.

3. Fully enclosed wet braking system: sets a new standard for safety and durability

Forest descents are long and heavily loaded, and the reliability of the braking system is directly related to the safety of life and property. The drive axle uses a traditional dry brake, and all series are equipped as standard with a fully enclosed multi-disc wet braking system. The brake linings are completely immersed in cooling oil, which provides three main advantages: firstly, huge braking torque and linear and stable response, allowing you to ride long distances and heavy loads without fear descents; second, excellent resistance to thermal decay, stable performance under continuous braking, and extremely high safety; Third, the fully enclosed design eliminates the ingress of sawdust, sediment and moisture, and the brake life can be several times that of dry brakes, almost reaching the same life of the drive axle, which significantly reduces the frequency and cost of maintenance. This system provides forestry equipment with braking guarantee comparable to mining equipment.

4. Hydraulic differential lock: extremely non-slip, ensures control on any terrain

For low-traction roads such as mud, ice, snow and fallen leaves in forested areas, the LTP75 drive axle is equipped with a quick-acting hydraulic differential lock. When the system detects one-way wheel slip, the driver can lock the differential with the touch of a button via a switch, transferring 100% of the torque to the attached wheels and instantly restoring strong traction. Compared to an automatic limited-slip differential, hydraulic Positive locking is more direct and reliable, especially in the case of extreme traction resistance, which increases the likelihood of recovery. This system ensures that no matter how difficult the slippery road surface is faced, the equipment can have maximum flotation, and downtime caused by slippage is minimized.

3. Precision manufacturing: millimeter-level craftsmanship according to ISO system

Achieving superior design requires exceptional craftsmanship. The LTP75 drive axle is home to a state-of-the-art intelligent factory that operates in strict accordance with the ISO 9001 quality management system. From the storage of raw materials to the delivery of finished products, every link is under systematic and documented control, ensuring absolute consistency and traceability of product quality.

When machining key parts, key components such as the drive axle housing, differential housing and main gear housing are precision machined on special fixtures. This special tooling ensures consistent alignment and ultra-high positioning accuracy of each part in mass production. Once machining is completed, no spot inspection is required, but 100% complete control of all key dimensions and geometric tolerances. A high-precision three-coordinate measuring machine (CMM) like an “industrial microscope” that monitors any deviations at the micron level and generates traceability reports for each part to ensure it fully meets the strict specifications of the design drawings.

During the assembly and assembly testing phase, an experienced team of assemblers transforms precision parts into high-performance units according to standardized operating procedures. However, completion of assembly is not the end point. Each LTP75 drive axle must undergo a “final inspection” on a dedicated comprehensive test bench before leaving the factory. An idle test checks the smoothness and noise level of operation; Load test simulates real working conditions to check the efficiency of torque transmission; Leak testing ensures that there are no leaks when spraying under high pressure. Only after all test samples meet the standards can this drive axle be “factory licensed” and delivered to the customer. This kind of paranoia about quality is the cornerstone of product reliability.

4. A true battle triumph: the first series of load tests received high customer praise

Laboratory data is modest, while market feedback is warm. This new drive axle, specifically designed for material collectors, has now successfully completed vehicle loading tests on the first batch of five components. This equipment was placed in real forest conditions and underwent a rigorous operational evaluation over several months.

Throughout the test cycle, the material collection device equipped with the LTP75 drive axle operated smoothly, reliably and did not suffer from any quality failures associated with the drive axle. It perfectly adapts to complex environmental changes - from spring and autumn mud to snowy winter. Its all-terrain design allows drivers to tackle challenging terrain with increased confidence. The powerful traction force ensures comfort when hauling large logs, and the wet braking system provides reliable braking force guarantee on long descents. sections.Initial feedback from early adopters has been very positive, with them particularly praising the drive axle for its “strength, stability and virtually no need to worry about maintenance.” This fully validates the drive axle's excellent adaptability and durability under harsh operating conditions, demonstrating that it has evolved from a superior design to a sophisticated, reliable and trustworthy final product.

5. Looking to the future: Continue to promote the modernization of global forestry

The successful research, development and testing of the LTP75 series forestry machine drive axle is not only the concentrated embodiment of our company's technical strength in the field of special vehicle transmission, but also the fulfillment of our deep commitment to forestry customers around the world. We deeply understand that every equipment used in forestry carries a heavy responsibility to improve efficiency, ensure safety and create value.

Looking into the future, we will continue to focus on customer needs and continue to improve our products. R&D efforts are already developing a more advanced version with built-in intelligent temperature control and wear monitoring sensors, aimed at ensuring timely maintenance and further reducing the overall operating costs of users. At the same time, we will continue to improve our service network and spare parts supply system covering key forest areas around the world, so that our customers can receive timely and professional technical support no matter where they are located.

We firmly believe that with its innovative balance box drive axle design, powerful four-speed gear ratio, wet braking safety guarantee and superior reliability that has been double-tested by national laboratories and real-world operating conditions, the LTP75 Series drive axle will become the preferred power solution for global forestry machinery and equipment manufacturers and end users, and to work with partners to advance the global forestry industry towards more efficient, safer and intelligent new era.