Welcome customers with quality and win-win technology! SANY delegation highly praised Shandong Lutong drive axle

Recently, a delegation from the world's leading engineering technology enterprise, Sany Heavy Industry (SANY), made a special visit to Shandong Lutong Machinery Technology Co., Ltd. (hereinafter referred to as Shandong Lutong). The visit was not only a targeted inspection of a key component supplier by the industry giant, but also an important opportunity for Shandong Lutong to showcase its manufacturing capabilities in the development and manufacture of drive axles. As a leading enterprise in this field in China, Shandong Lutong, with more than 30 years of experience, has long been a strategic partner of many leading engineering equipment manufacturers, and SANY's visit is a strong confirmation of this.

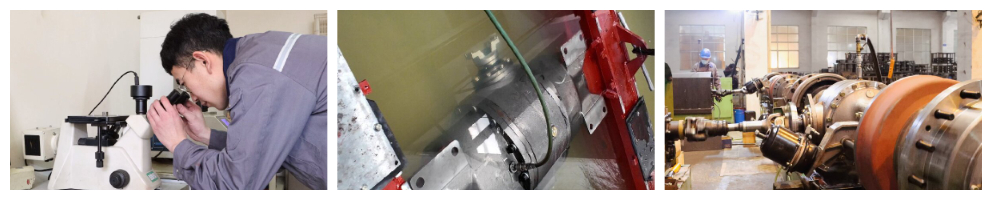

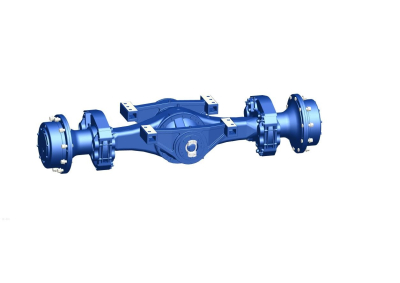

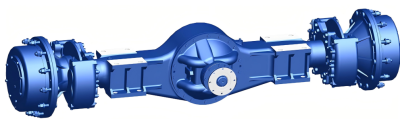

Since its establishment, Shandong Lutong has focused on its core business of producing drive axles for engineering, agricultural and mining machinery. Through a development strategy aimed at "specialization and excellence", the company has achieved an advantage of scale with an annual production capacity of more than 50,000 sets. Its products are supplied to more than 30 provinces and cities in China, and are also exported to Russia, Belarus, Iran and other countries and regions. The company maintains long-term and stable cooperation with such well-known industry enterprises as SANY, XCMG, LiuGong, Shantui and others. The SANY delegation visited three key areas: the R&D center, the intelligent production floor, and the quality control and shipping area. Through personal observation, technical advice and data verification, they gained a comprehensive and in-depth understanding of the comprehensive capabilities of this specialist drive axle manufacturer.

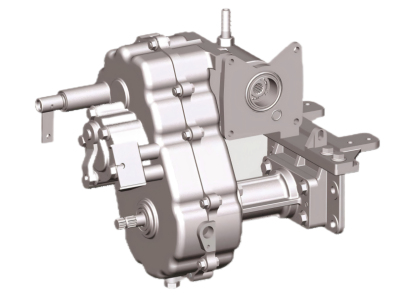

Research and development capacity is the key competitiveness of Shandong Lutong and the main focus of the SANY delegation. The company's technical director systematically presented the technical advantages of main products such as wheeled excavator axle and loader axle. Shandong Lutong has established a professional development team of 20 people, with 3 senior engineers having more than 30 years of experience in drive axle development. This deep talent pool provides strong support for technological innovation. According to the requirements of different working conditions, the team develops customized products, each with its own characteristics. To date, Shandong Lutong has already obtained many patents related to drive axles.

Turning technical drawings into quality products - Intelligent manufacturing is the key to quality assurance at Shandong Lutong. The modernized exclusive production line for the company's drive axles became the focus of the delegation's attention. In the workshop, imported CNC machining centers accurately machine the key components of drive axles, the error is controlled within 0.005mm; Fully automated welding robots perform the work efficiently, the percentage of high-quality welds reaches 100%, and the efficiency is 3 times higher than with manual welding. What’s even more remarkable is that the workshop has a fully implemented MES (Manufacturing Execution System) system, which allows you to track the entire process - from recording data on the receipt of raw materials to the parameters of each production operation. This intelligent and detailed approach to production management ensures consistency in product quality—drive axles.

“Meeting product standards is not the end goal, our goal is customer peace of mind” is the quality philosophy that Shandong Lutong adheres to. At the quality control center, the delegation witnessed strict standards: incoming raw materials are tested for spectral composition and mechanical properties; finished drive axles are tested for static load, fatigue strength and tightness. The manager of the quality control department noted that the percentage of high-quality products produced by the company is consistently high. For example, the drive axles sent to Russia last year worked under continuous operation conditions without a single failure.

At the meeting, the SANY delegation highly appreciated the capabilities of Shandong Lutong, and representatives of Shandong Lutong, in turn, detailed the company's development philosophy and service commitments. They emphasized that the company's mission is to "provide more reliable drive axles for the engineering equipment industry." The company focuses not only on technological development and quality control, but also on the ability to provide customized services. According to the technical characteristics and operating conditions of different customers, the company can quickly respond and develop customized solutions, which is the key to winning the trust of many leading enterprises. At present, Shandong Lutong has established a perfect system of technical cooperation in the pre-sales stage, production support in the sales stage and rapid response in the after-sales stage. A dedicated service team working 24 hours a day ensures timely resolution of customer issues.

The visit of the SANY delegation was not just negotiations on cooperation, but a comprehensive demonstration of Shandong Lutong's capabilities across the entire value chain: from development and production to servicing drive axles. More than ten years of in-depth work, with technological innovation as the core, quality control as the core and focus on customer needs, has enabled Shandong Lutong to set the professional standard in the field of drive axles. In the future, the company plans to continuously dedicate 8% of annual revenue to research and development, focusing on lightweighting and intelligentizing drive axles to continuously improve its core competitiveness. As an important supplier of key components for Chinese engineering machinery, Shandong Lutong will continue to rely on its own capabilities to promote the development of the industry, and work with industry giants such as SANY to promote Chinese engineering machinery brands to the global stage.