What is a drive axle and what is it for?

In the power supply systems of various heavy machinery, such as construction equipment, agricultural machinery, mining equipment, etc., the drive axle is undoubtedly the central unit connecting the engine output power to the wheel drive actuator, and is rightfully considered the “power heart” of the equipment.It not only performs the key function of power transmission, but also its structural strength, transmission efficiency and stability directly determine the working efficiency, operating safety and long-term stability of the entire equipment under complex operating conditions.For companies operating in fields such as construction, mineral resource development, and large-scale agricultural production, a thorough understanding of the basic functions and technical characteristics of the drive axle is an important prerequisite for accurately selecting suitable spare parts for equipment, reducing operating costs, and improving production efficiency.Shandong Lutong, as a leading domestic enterprise specializing in the research, development and production of drive axles, with more than 30 years of experience in the industry, will comprehensively analyze the functional value of drive axles based on its own technical developments, and systematically demonstrate the company's ability to produce high-quality drive axles adapted to various harsh operating conditions.

The main function of the leading bridge is to ensure efficient and stable operation of heavy equipment.

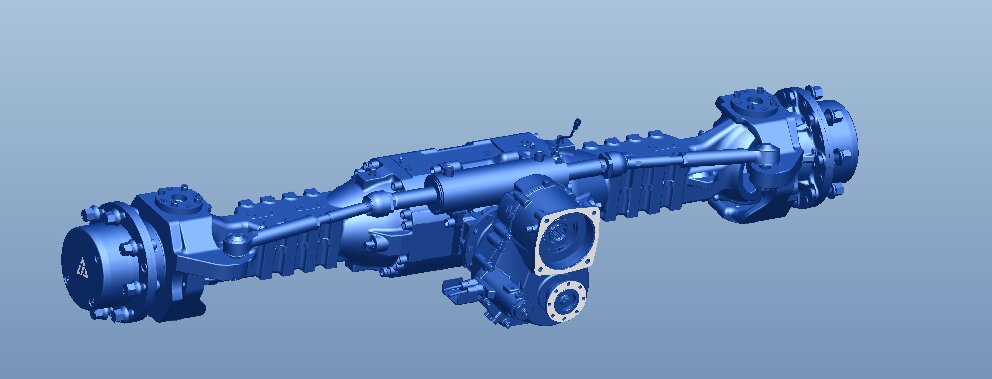

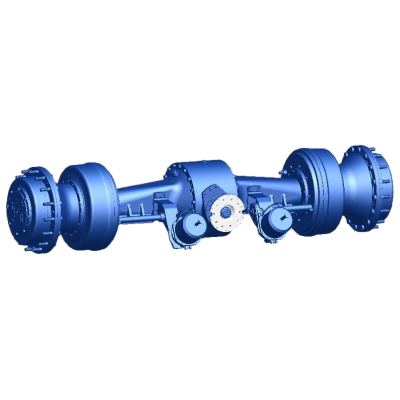

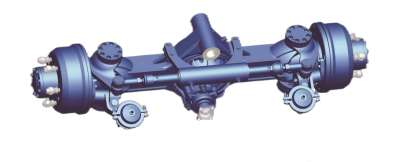

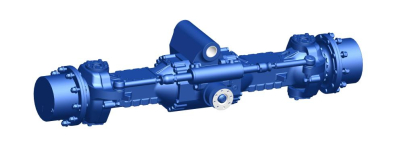

From a structural perspective, the main axle typically contains key components such as the main gearbox, differential, axle, and axle housing, and represents a highly integrated power transmission system. The main axle is not the only component of the transmission in heavy equipment operation, but it performs many important tasks such as power conversion, direction control, load support, and safe braking. Its main functions are mainly concentrated in the following four dimensions, and each function interacts with each other to ensure stable operation. equipment operation.

1. Power transmission and torque enhancement: creating the basis of the driving force of the equipment.

The main function of the drive axle is to transmit the power generated by the engine through the main drive gear to reduce the rotation speed and simultaneously increase torque, and then accurately transfer it to the drive wheels through the differential and axle shafts, ultimately converting it into driving force for equipment. The main drive axle of construction machinery, independently developed by Shandong Lutong, meets this key need by optimizing the engagement parameters of the gears and the main transmission design, using high-strength alloy gears to enhance transmission efficiency. Its torque amplification coefficient is 15% higher than the industry average, which allows for easy adaptation to the needs of mining equipment in conditions of heavy loads and low speeds, ensuring stable output power even at full equipment load.

2. Direction change and differential adjustment: increased maneuverability and tire lifespan.

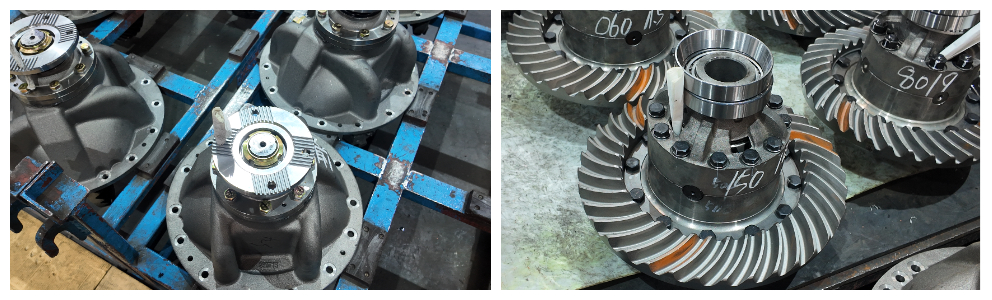

The power output of the engine is usually in a horizontal direction, while the direction of rotation of the wheels is vertical. The bevel gear pair of the main gear inside the drive axle is responsible for changing the direction of torque transmission by 90 degrees, ensuring a rational connection of the power transmission path. More importantly, when turning equipment, the turning radii of the inner and outer wheels are different, and if the rotation speed remains the same, it will cause the tires to slip and rub against the ground, which will not only worsen tire wear, but also affect the stability when turning. The differential in the drive axle can automatically adjust the difference in rotational speed of the inner and outer wheels, ensuring that they always roll cleanly.

3. Load-bearing capacity and stability: creating a “safety line” for equipment operation.

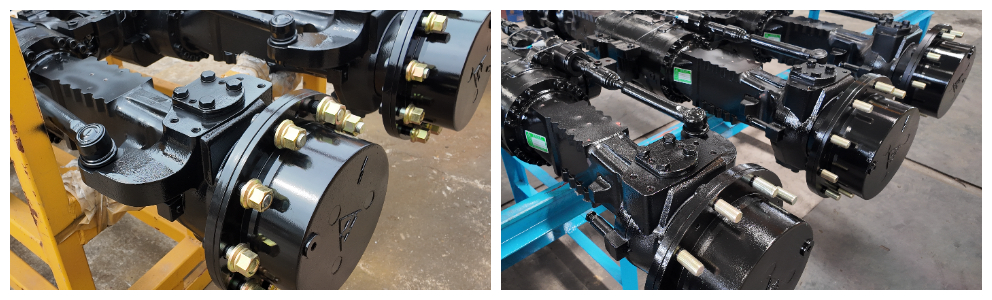

The drive axle housing, as the main load-bearing component, must simultaneously withstand the vertical weight of all equipment, longitudinal traction forces arising during operation, and lateral shock loads arising during movement. Like the "spine" of the human body, it provides reliable support for equipment. Especially in harsh operating conditions such as mining and construction, where equipment must travel on uneven roads and is often loaded, the load-bearing capacity of the drive axle directly affects the safety of the equipment. In the production of axle housings, Shandong Lutong uses high-strength alloy structural steel as raw materials, which is processed through a variety of precise processes, including forging, welding, heat treatment, etc. The tensile strength of the crankcase exceeds 800 MPa. All crankcase products must undergo rigorous testing, including 10,000-hour continuous load tests, thermal shock tests, etc., to ensure that they maintain stable load-bearing performance in both severe cold -40°C and high temperature up to 60°C, as well as rough and bumpy roads in mining areas, creating a safety line for equipment operation.

4. Ensuring braking safety: controlling risks during equipment operation.

Heavy equipment operating conditions are challenging, the workload is heavy, and the reliability of the braking system directly affects the safety of the operator and equipment. The drive axle typically integrates a braking system that, through friction between the brake pads and the brake drum, quickly converts the machine's kinetic energy into heat and dissipates it, allowing for planned and emergency shutdown of the equipment. Compared with traditional dry brake systems, the wet brake system installed by Shandong Lutong on the drive axles of construction equipment has significant advantages: heat dissipation efficiency is increased by 30%, which can effectively avoid brake failure due to long-term braking; In addition, the friction linings of wet brakes wear out more evenly, and their service life is extended by more than 2 times compared to conventional dry brakes. Based on testing, the response time of this braking system is 0.3 seconds faster than standard products on the market, giving the operator more reaction time in emergency situations and significantly improving equipment safety.

Shandong Lutong: Setting the benchmark for high quality drive axle with full cycle capabilities

Excellent drive axle performance is not possible without strict control at all stages: from design and R&D to raw material procurement, production and quality control. Since its establishment, Shandong Lutong has always aimed at "building a national and global leading drive axle brand" and, with strong R&D capabilities, advanced production equipment, comprehensive quality system and efficient service, has become a model enterprise in the drive axle industry in China. The company's products cover not only the main domestic construction equipment production regions, but also are exported to many countries and regions of the world, providing a reliable power base for various types of heavy equipment.

Regarding advanced equipment:

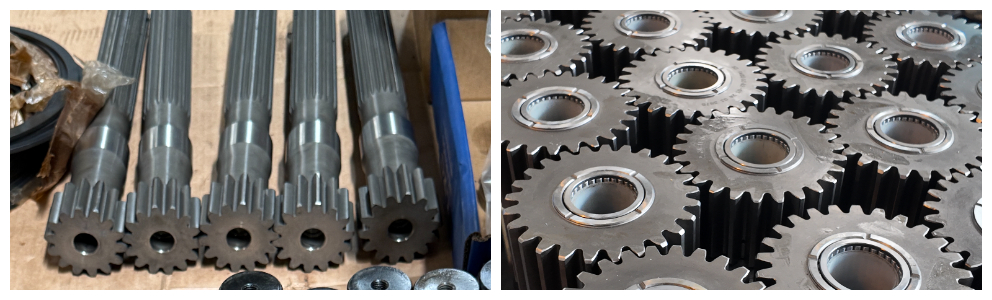

Shandong Lutong adheres to the concept of "equipment intelligentization, product precisionization", having cumulatively invested 120 million yuan in acquiring international advanced production and testing equipment. Among them, several Siemens (Germany) CNC machining centers have realized comprehensive processing of key components such as axle housing and gears with high processing precision, 40% higher than traditional equipment, effectively ensuring the assembly accuracy between components and transmission stability. During the inspection phase, the company is equipped with coordinate measuring machines to conduct 100% inspection of all dimensions and functional tests of major loader and excavator axle components such as final drive gears, differentials, axle shafts, etc., ensuring each component meets design standards. In addition, the company has created a digital production management system that allows tracking data of the entire process from the receipt of raw materials to the warehouse to the shipment of finished products, which further improves the accuracy of control of the production process.

Regarding the technical team:

then the Shandong Lutong company formed a research team, which is composed of 20 senior engineers. Team members have an average of more than 10 years of experience in research and development in the field of leading bridges and have participated in the development of several national standards in the area of construction equipment. The team of research and development experts focuses on market demand, paying special attention to research and development of leading excavator-loader bridges, leading mining equipment bridges, and leading large agricultural equipment bridges, and has achieved several technological breakthroughs in the areas of improving energy transfer efficiency, optimizing adaptation to low temperatures, and lightweight design.

Regarding advanced equipment:

Shandong Lutong adheres to the concept of “intelligent equipment and processing products” and has invested a total of 120 million yuan in introducing international advanced production and testing equipment. These include several sets of German Siemens CNC machining centers, which realize comprehensive processing of key components such as axle housing and gears. The processing precision is high, 40% higher than traditional processing equipment, which effectively guarantees the assembly accuracy and transmission stability between machine tools. components. During the testing process, the company is equipped with a three-axis measuring instrument to conduct 100% full-size testing and performance testing of major components such as the main gearbox, differential and backhoe loader drive axle axle to ensure that each component meets design standards. In addition, the company has implemented a digital production management system to ensure the traceability of all process data from raw material storage to product storage, which further improves the accuracy of production management process.

Regarding quality control and supply:

then Shandong Lutong has developed a three-level quality control system covering “raw material entering the factory - processing process - finished product leaving the factory”, and has developed internal control standards in the enterprise that are far superior to industry standards. When raw materials enter the factory, key materials such as steel, gears, bearings, etc. are tested for mechanical properties and chemical composition, and unqualified materials are resolutely returned; During processing, 12 quality control points are established and samples are collected by full-time quality inspectors. Before the finished product leaves the factory, each drive axle must undergo more than 20 strict tests, such as torque testing, fatigue life testing, sealing testing, and high and low temperature adaptability testing. Only after completing all the tests, passing the qualification and receiving the test report, you can click on the delivery link. In terms of logistics and distribution, we have created exclusive logistics channels for international customers and cooperate with renowned logistics companies such as COSCO Shipping and Russian Railway Logistics to provide reliable packaging for products and door-to-door delivery from factory to customer site, which allows it to be 3-5 days shorter than the industry average, which greatly improves the quality of service. clients.

As the main power component of heavy equipment, the performance of the drive axle is directly related to the efficiency and safety of equipment operation, and its quality is an important indicator of the competitiveness of the enterprise. Shandong Lutong will always adhere to the business philosophy of “quality first, advanced technology”customer first”, continue to increase investment in research and development and constantly optimize the performance of core products such as construction machinery drive axles, loader and excavator drive axles, and introduce customized solutions for various industries and working conditions. In the future, Shandong Lutong will continue to expand the international market and create high-quality products, professional technical support and perfect after-sales service is another value for customers around the world. world. If you want to know more technical parameters, application options or product purchasing information for drive axles, please visit the official website of Shandong Lutong for consultation, 或发送邮件至sales@lutongaxle.com . We will serve you with all our hearts.