What You Don't Know About the Drive Axle: The "Behind-the-Scenes Hero" of Efficient Construction Equipment Operation

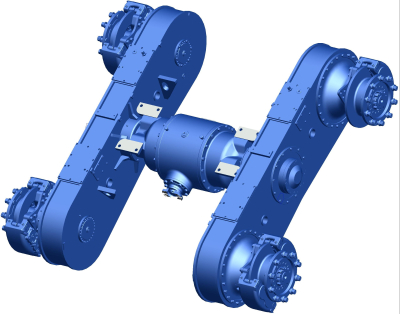

In the field of construction equipment, the leading bridge, as the main component of the transmission, directly affects the energy characteristics, reliability and life of the equipment. However, many users do not know the principle of its work and technical details. Today we will talk about the “hidden functions” of the leading bridge and the latest technological developments in the industry to help you choose and serve this key component from a scientific point of view.

Three “cold keys” of the leading bridge

“Hoorance Password” to block differential

The function of blocking the differential of the leading bridge is often underestimated, but in difficult operating conditions, such as dirt and sand, it can force the left and right wheels to rotate synchronously to avoid slipping on the one hand. Some high -class leading bridges are already equipped with electronic automatic locking technology, which avoids problems without manual intervention.

The light -made design hides an incredible effect

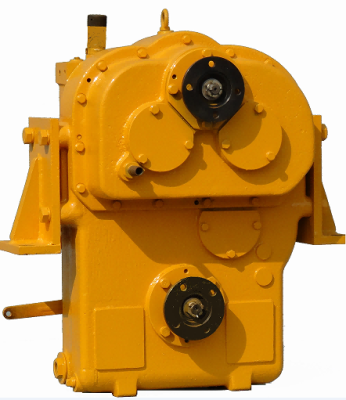

In modern leading bridges, high -strength alloys and topologically optimized structures are used, which allow you to reduce weight by more than 20% without prejudice for the carrying ability. For example, the integrated design combines the axis housing and the brake into a single whole, which not only reduces fuel consumption, but also increases the efficiency of heat removal.

The era of "smart leading bridges" came "

Some new drive axles are equipped with built-in sensors that can monitor oil temperature, gear engagement and load distribution in real time and transmit data via the Internet of Things to enable predictive maintenance and reduce unexpected failures and downtime.

Industry pain points and innovative solutions

Risk Factor 1: Oil leakage under extreme operating conditions

Innovative solution: multi-layer seal (such as oil seal + labyrinth seal) + heat-resistant synthetic rubber fabric to adapt to environmental conditions from -40℃ to 120℃.

Problem 2: High cost of preservation

Innovative solution: modular design allows inclined parts such as gears and bearings to be replaced one by one without the need for standard disassembly, saving more than 50% maintenance time.

How to choose the right drive axle?

Appropriate working conditions: Mining tools must be designed for increased wear resistance, while agricultural construction equipment requires anti-corrosion coatings.

Pay attention to the speed ratio: a large speed ratio is suitable for heavy-duty and low-speed work, while a small speed ratio ensures efficient transportation.

Certification standards: Products certified by ISO 9001 or CE can better guarantee long-term stability.

The technological evolution of leading bridges indicates that construction equipment is developing in the direction of increasing efficiency and intelligence. Shandong Lutong, a manufacturer of leading bridges with 32-year research and development experience, constantly seeks to provide customers with individual decisions. Welcome to our official website or contact a team of engineers to get an exclusive technical consultation!