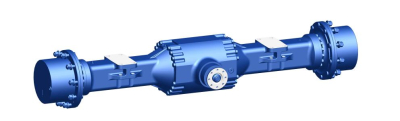

The main components of Shandong Lutong's new timber harvesting axle and fork-mounted axle have entered the precision processing stage.

July 1, 2025 - Shandong Lutong Machinery Co., Ltd. She announced that the recently developed leading axis for collecting logging material LTP75 and a special leading axis for loading the forks entered the stage of precision processing of the main components. These are two products developed for special working conditions, use a number of innovative technologies, which indicates the major achievements of the company in the field of special leading bridges.

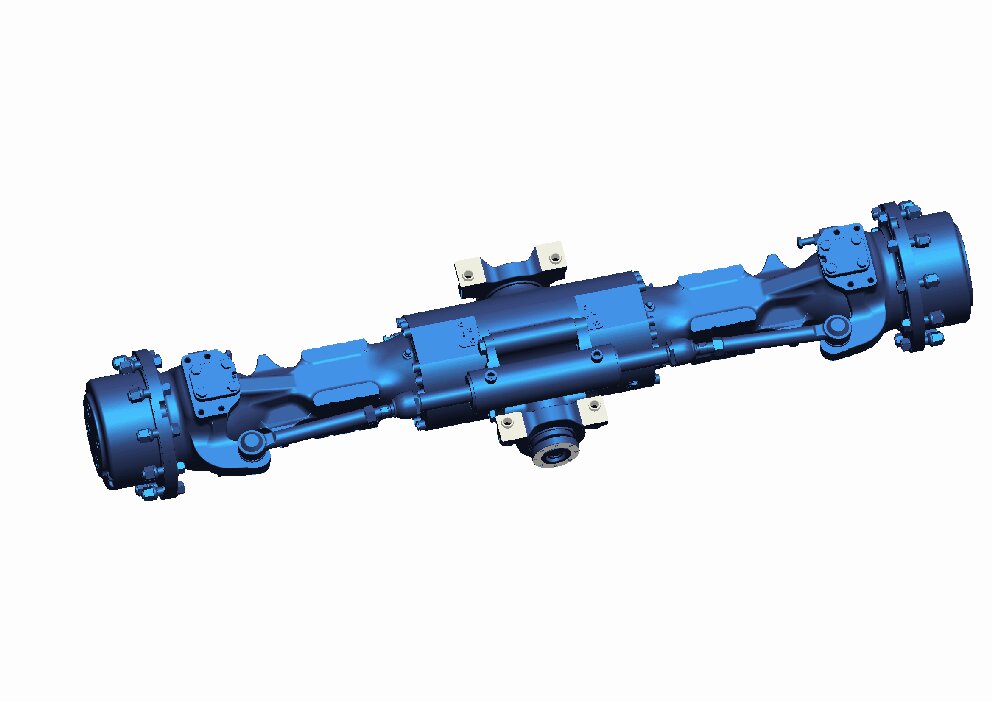

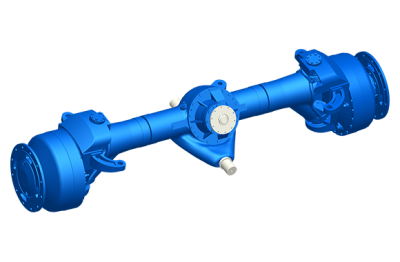

【Technical characteristics of the leading bridge of the collector of the logging material LTP75】

1.Four-stage deceleration system with large gear ratio provides excellent torque, and the traction force is 40% higher than traditional models.%

2.The power consumption offset design is matched with the rotary design of the rotary bearing, and the throughput is improved by 50%

3. Closed multi-disc wet braking system ensures stable braking.

4.The response time of the hydraulic differential lock is less than 0.3 seconds, and the anti-skid performance on complex terrain is excellent.

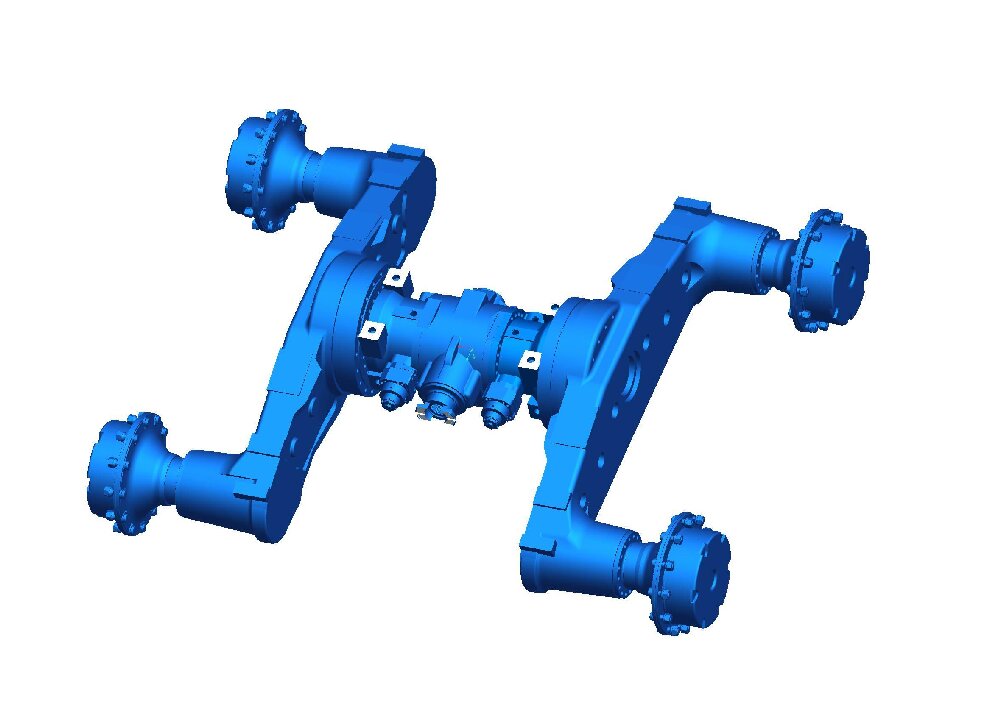

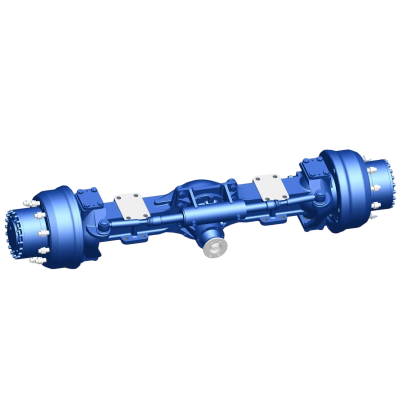

【Technological Breakthrough in the Creation of Special Forklift Drive Axle】

1.The two-stage deceleration design provides various speed ratios and the transmission efficiency is improved by 15%

2. The braking torque of the built-in wet braking system increases by 20%

3.The overall design of the swing frame reduces the car's center of gravity by 15%, and the installation efficiency is increased by 40%.

4. Intelligent differential system (self-locking differential + forced differential lock) to improve cross-country ability in difficult operating conditions by 35%

The first batch of samples is currently undergoing precision machining in the company's digital workshop, with automated machining centers used to ensure the accuracy of key components.Production

The production department, in particular, has strengthened quality control :

1. Inward the system for tracking the entire process as a whole

2.100% Operational determination of the size of the keys

3. Metallographic analysis of the organization of materials

4. Continuity of accuracy of gear engines

We will conduct three -month stand tests and verification of the actual working condition to make sure that the product characteristics meet the design requirements. At this time, key customers will be invited to conduct tests and evaluations on the spot. SHANDONG LUTONG will continue to invest in research and development to provide more professional and reliable drive solutions for users of construction equipment around the world.