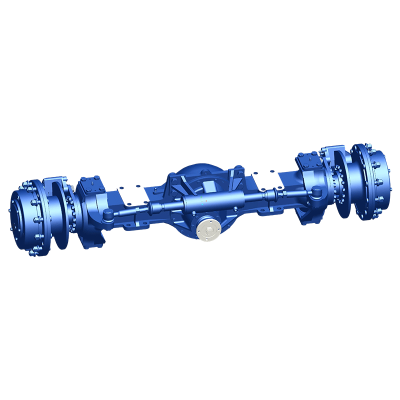

SHANDONG LUTONG introduces dual-series drive axles for forklifts, providing highly efficient and reliable power support

In the area of construction equipment, the loader is similar to a tireless steel giant, and the leading bridge is not only its "spine", which provides sustainable movement, but also the "heart", which gives powerful energy. For more than 30 years, Shandong Lutong has been working in the production of leading bridges for construction equipment, invariably adhering to the principles of “reliability, efficiency, innovation” and continuing to provide leading world manufacturers of equipment with powerful energy.

The thirty -year development path is not only the process of accumulating technologies, but also a certificate of adherence to skill. We perfectly understand the importance of the leading bridge for the loader, so each model from design to production embodies the efforts of the whole team. Thanks to many years of experience and constant innovation, our leading bridges demonstrate outstanding stability, and the level of accident rate is much lower than the average in the industry, which has gained wide recognition in the market. In China, we maintain close cooperation with the leaders of the industry, such as Sany Heavy Industry, Liugong and Longong. In the international arena, our cooperation with companies such as Amkodor, St. Petersburg PTZ and the Russian UMG, has been going on for many years, and the characteristics of products have been highly appreciated by foreign customers. Choosing our leading bridges, you choose the trouble -free operation of equipment, reliable production support and high performance.

Facing the changes in the construction machinery industry, Shandong Lutong has already prepared itself by adopting a two-series product strategy to meet the new trends.

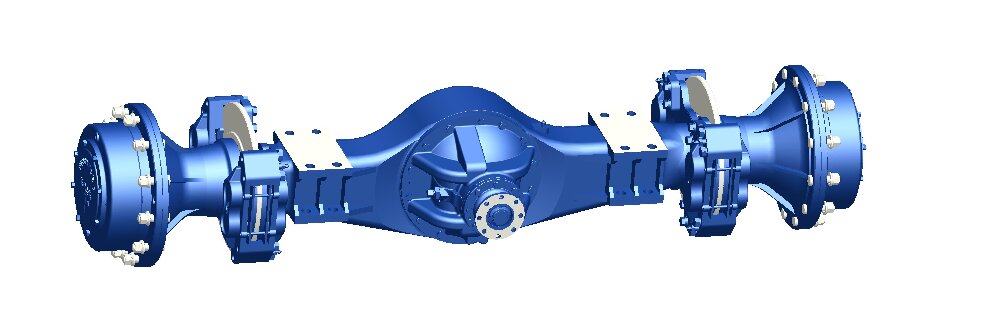

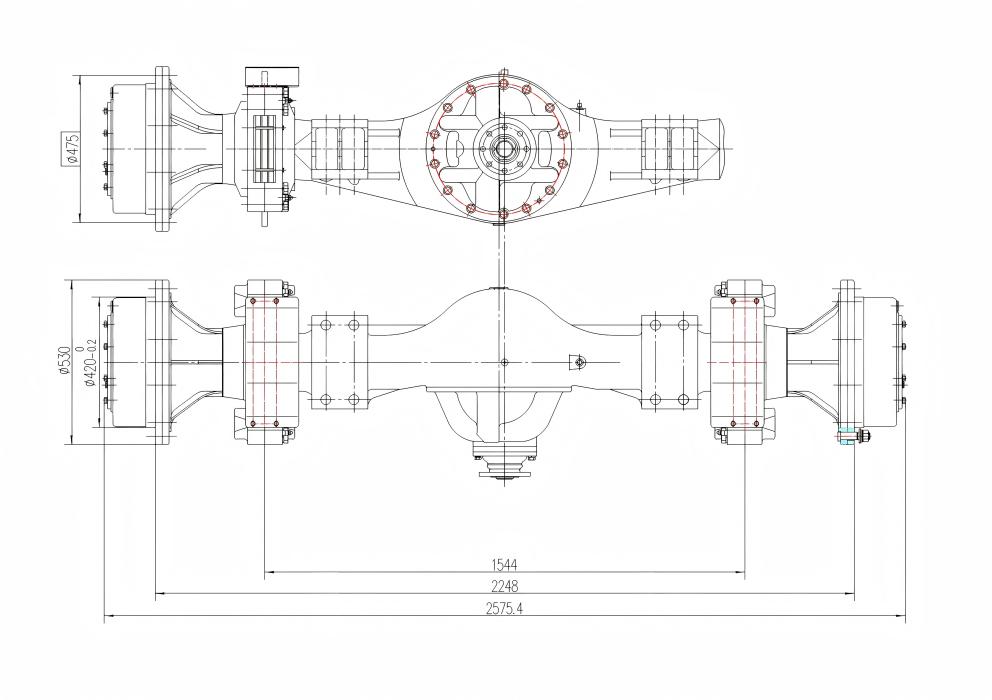

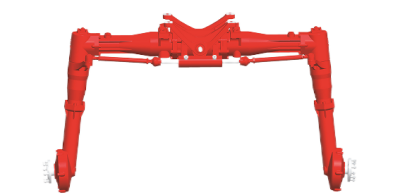

Drive axle for traditional loaders: powerful and durable

Structurally offers a choice between swinging and basic types, uses a two-stage reducer transmission, is equipped with a conventional differential or no-spin anti-circus differential for flexible satisfaction of the needs of various working scenarios. The main gear uses the spiral-conical gears Gleason, which provides a high efficiency of transmission and effectively reduces working noise. The NGW wheeled planetary gear has a rational and compact design, which additionally increases the efficiency of power transmission. The brake system uses disk brakes with a large brake point, reliable and quick operation, wet brakes with improved characteristics specially designed for loaders of the ZL50 series are available in a higher class. Whether it is difficult working conditions in mines, continuous work in ports or difficult conditions at large construction sites - he went through severe trials, demonstrating stable performance. In dusty mines, lively ports or at large -scale construction sites, it will become a reliable support for traditional loaders, ensuring their continuous and efficient work.

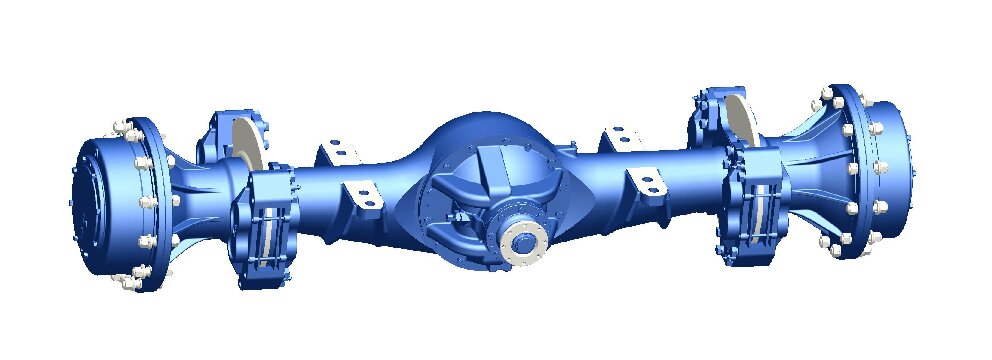

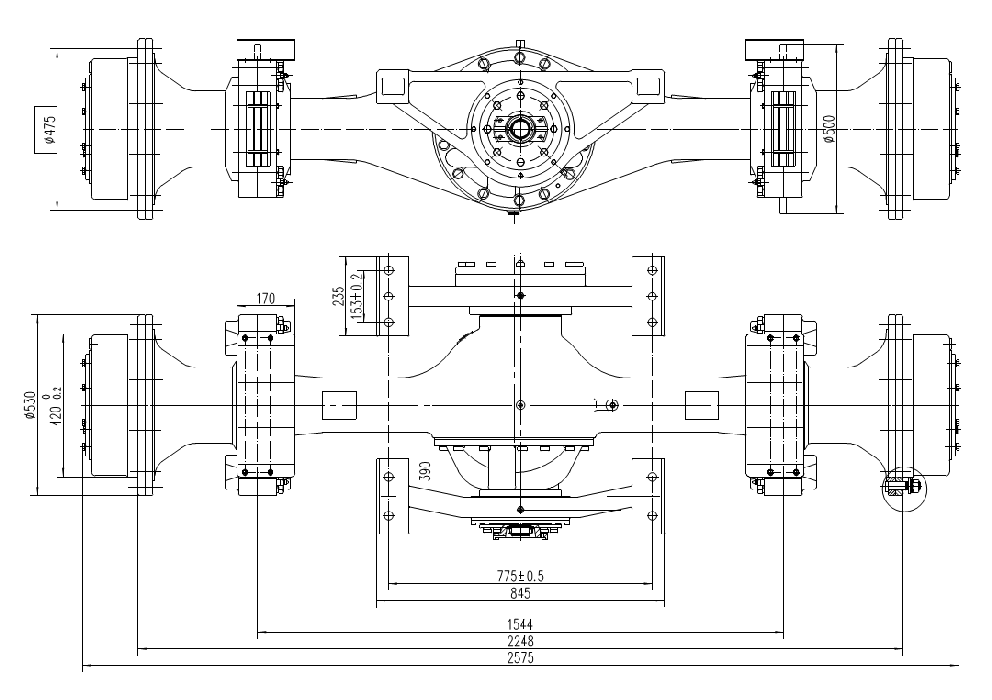

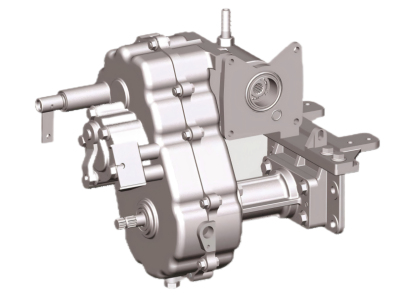

Drive axle for electric forklifts: an excellent choice for the transition of construction equipment to electric traction

The main program uses the conical oerlikon gears with high strength and low noise, which perfectly meets the requirements for the characteristics of electrical equipment. Wheel gear also uses the NGW planetary mechanism, processed by accurate grinding grinding, which provides a double advantage of high transmission strength and low noise at a compact common structure. The bridge case has a rectangular cross section and is made by steel casting method, providing good rigidity and high carrying capacity, which creates a strong basis for stable equipment. The brake system uses disc brakes with a large brake moment, smooth and reliable operation, the differential can be equipped with no-spin anti-circus system, suitable for electric loaders of the ZL50 series. It has a high torque, satisfying the needs of electric loaders in power; low noise level, showing itself perfectly in conditions sensitive to noise; As well as the simplicity of maintenance, which allows you to reduce the operational costs of equipment. Scenarios such as storage facilities, urban construction and environmentally friendly mines, where high requirements for the ecology and noise level are ideal for its use, contributing to the green development of the industry.

By choosing our drive axles, you receive the following real guarantees:

Consistent quality is our confidence

We adhere to the principles of precision manufacturing, with strict quality control at every stage - from raw material selection to production. A full cycle of testing, combined with a sophisticated material tracking system, ensures that every drive axle manufactured meets the highest standards, and the failure rate is significantly lower than the industry average.

Ultra-low accident rate ensures safety of equipment and personnel

When designing, we take into account multi-level protection, including precise overload protection, which minimizes potential risks during equipment operation and reduces operational risks.

High adaptability meets various needs

Whether traditional diesel forklifts or new energy electric forklifts, models with different load capacities or special work requirements - there is a drive axle to suit everything.

Professional service will relieve you of worries

A team with 30 years of experience provides comprehensive support at all stages: from model selection and installation to after-sales service. Technical specialists will give recommendations based on your needs, and the service team will respond promptly and promptly resolve any problems that arise.

Embrace the change, achieve success together! Whether you are using traditional power plants or switching to electric traction, Shandong Lutong is your reliable partner in the field of drive axles. Contact us today through the official website or service hotline to equip your forklift with a powerful "heart" and start a new chapter of highly efficient and reliable production together!

- Previous : Shandong Lutong Introduces New Generation of Backhoe Loader Drive Axles, Setting New Standard in Russian Construction Equipment Market

- Next : Drive axle withstands harsh high altitude tests with flying colors as loaders confidently operate at the forefront of wind power development in Yarlung Tsangpo Valley