Shandong Lutong Introduces New Generation of Backhoe Loader Drive Axles, Setting New Standard in Russian Construction Equipment Market

(July 30, 2025, Taian) against the background of growing investments in Russia's infrastructure, demand for high-performance drive bridges for construction equipment demonstrates structural growth, especially for excavators-loaders-key equipment in the field of utilities, agriculture and mining. The company Shandunskaya company for the production of equipment for heavy industry Lutun, an LLC, a leading Chinese manufacturer of drive bridges for construction equipment, announced the access to the Russian market of new generation of leading bridges for excavators-loaders, offering breakthrough technologies to overcome industry restrictions.

1. The market of excavators-loaders in Russia: opportunities and challenges

According to the National Agency for Industrial Information (PBU), sales of excavators-loaders in Russia for the first half of 2025 increased by 42%, which made this segment one of the most dynamic in the industry of construction equipment. This growth is associated with the state program of subsidies for 7.8 billion rubles, which provides for priority purchases of domestic equipment and encouraging import substitution of key components, including drive bridges of construction equipment. However, the share of Chinese brands in the Russian market decreased from 68.9% in 2024 to 64.7%, which revealed the shortcomings of traditional drive bridges in adaptation to difficult operating conditions and high maintenance costs.

Russia's unique geographic conditions place special demands on construction equipment drive axles: the low temperatures of Siberia test the reliability of braking systems, the muddy conditions of the Caucasus require increased cross-country ability, and the high humidity of the Far East requires corrosion resistance. The new generation of drive axles from Shandong Lutong has been specially optimized to meet these challenges.

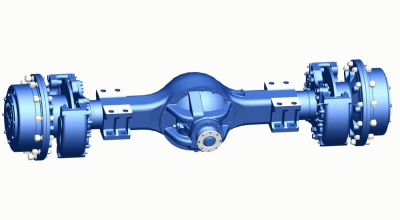

2. Shandong Lutong Drive Axles: Rethinking Backhoe Loaders

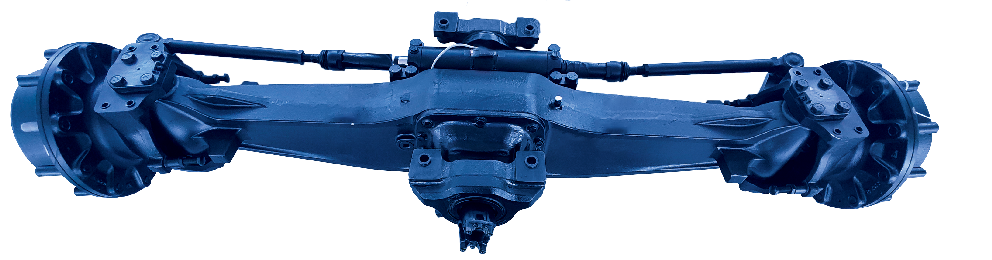

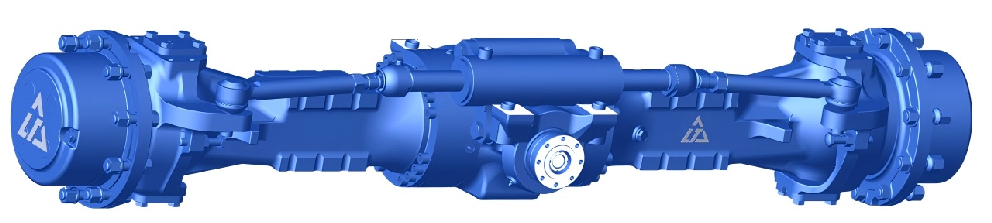

Front Drive Axle: Balancing Safety and Efficiency

One-piece body: increased load capacity for intensive use.

Power steering: fast response even at low temperatures.

One-piece frame construction: lower center of gravity and standardized mounting holes for quick installation.

Rear drive axle: reliability in difficult conditions

Multi-disc wet brakes: stability under long braking periods.

Dual-mode differential: automatic torque distribution and forced locking for off-road use.

Modular platform: compatibility with various equipment models.

3. Localization: from supplies to technology partnerships

Shandong Lutong cooperates with 20 Russian equipment manufacturers. For the local market, the drive axles were modified:

Improved frost resistance: special oils and seals.

Simplified maintenance: extended oil change intervals and quick-change filters.

Certification: Compliance with strict safety requirements.

"Our products have a zero failure rate in Russia. We have reduced delivery times by 30% while maintaining the highest quality," notes a company representative.

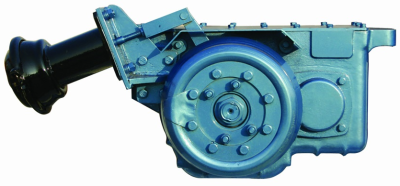

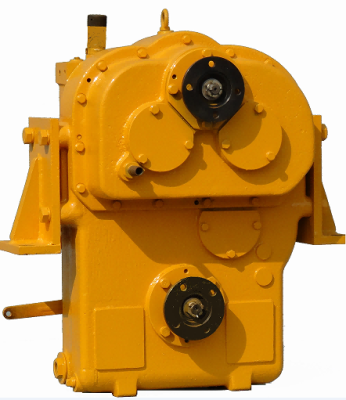

4. Technological innovation as a response to import substitution policy

Shandong Lutong focuses on innovation in the production of construction equipment drive axles. Key components such as planetary gears are produced on automated lines with strict quality control. This strategy allowed the company to strengthen its position in the premium segment market in 2025.

5. Drive axles as a key to the construction equipment market

Against the backdrop of the “Turn to the East” strategy and the “One Belt, One Road” initiative, Shandong Lutong offers proven solutions with 30 years of experience. “We do not just supply components, we set new standards for the industry,” the company says.

- Previous : Shandong Lutong Heavy Industry Equipment Co., Ltd. Introduces New Generation of Telescopic Handler Axles: Innovative Technologies for the Global Special Equipment Market

- Next : SHANDONG LUTONG introduces dual-series drive axles for forklifts, providing highly efficient and reliable power support